Abstract

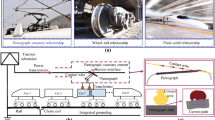

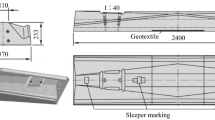

Nowadays, the sleeper, railroad bed, welding technology and materials of the high-speed & heavy-load Continuous Welded Rail (CWR) have been improved greatly. However, the orientation relationship between welding surface and rail is still orientation structure, which appeared 185 years ago in UK, namely, the welding surface is normal to the longitudinal direction of the rail. Thus rail welds are subject to vertical pure shear stress, lateral pure shear stress and axial pure tensile stress. Pure shear stress and pure tensile stress are both dangerous stresses, which result in failure of welds under high-speed & heavy-load condition for a long time. When the wheels pass rail welds, it is difficult to avoid vertical bumping and lateral vibration. In order to solve these problems, in this paper we put forward the single inclined welding surface having dip angle α with the lateral rail or dip angle β with the vertical rail and analyze the position geometry and stress state. Thus the vertical bumping and lateral vibration are basically eliminated, then the bearing capacity of the welding surface is significantly improved, and the stress of axial pure tensile and lateral pure shear of the welding surface is reduced.

Similar content being viewed by others

References

Shen Z Y. On the study of high-speed railways and trains (in Chinese). J Vib Meas Diagn, 1998, 18(1): 1–7

Jin X S, Wen Z F, Zhang W H, et al. Development status of world railway and its key mechanics problem (in Chinese). Eng Mech, 2004, (21): 90–104

Wen Z F. Study on rail corrugation (in Chinese). Doctoral Thesis. Chengdu: Southwest Jiaotong University, 2006

Mutton P J, Alvarez E F. Failure modes in aluminothermic rail welds under high axle load conditions. Eng Failure Anal, 2004, 11(2): 151–166

Li Z I, Zhao X, Esveld C, et al. An investigation into the causes of squats-correlation analysis and numerical modeling. Wear, 2008, 265(9–10): 1349–1355

Song Y Q, Tao Y, Luo W W, et al. Welding structure of CWR with good running regularity and high bearing capacity (in Chinese). Chinese Patent, 200920249624.1

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Y., Luo, W. & Tao, Y. Static mechanics analysis of no bumping or vibration welding structure applied in high-speed & heavy-load CWR with single inclined surface. Sci. China Technol. Sci. 53, 3153–3160 (2010). https://doi.org/10.1007/s11431-010-4151-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-4151-9