Abstract

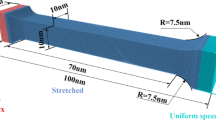

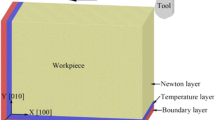

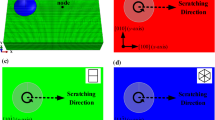

Large scale molecular dynamics simulations of nanomachining and stretching of single crystal copper are performed to analyze the machining process’ influence on the material’s mechanical properties. The simulation results show that the machining process will introduce interfacial defects inside the specimen and enhance the compressive stress beneath the surface. Generally speaking, interfacial defects lead to the decrease of the strength limit, while residue compressive stress can enhance the elastic limit and even the strength limit. Various machining parameters are adopted to investigate their influence on the mechanical behavior of machined specimen. Lower cutting speed and smaller cutting depth lead to less defects and greater residue compressive stress, which brings about better mechanical properties. The elastic limit increases by 36.8% under the cutting depth of 0.73 nm and decreases by 21.1% under the cutting depth of 1.46 nm. The strength limit increases by 7.7% under the cutting speed of 100 m/s and decreases by 28.2% under the cutting speed of 300 m/s.

Similar content being viewed by others

References

Deng C, Sansoz F. Enabling ultrahigh plastic flow and work hardening in twinned gold nanowires. Nano Lett, 2009, 9(4): 1517–1522

Dai L, Sow C H, Lim C T, et al. Numerical investigations into the tensile behavior of TiO2 nanowires: structural deformation, mechanical properties, and size effects. Nano Lett, 2009, 9(2): 576–582

Biener J, Hodge A M, Hayes J R, et al. Size effects on the mechanical behavior of nanoporous Au. Nano Lett, 2006, 6(10): 2379–2382

Schiotz J, Jacobsen K W. A maximum in the strength of nanocrystalline copper. Science, 2003, 301:1357

Li L, Ghoniem N M. Twin-size effects on the deformation of nanotwinned copper. Phys Rev B, 2009, 79: 075444

Olsson P A T, Melin S, Persson C. Atomistic simulations of tensile and bending properties of single-crystal bcc iron nanobeams. Phys Rev B, 2007, 76: 224112

Cao A J, Wei Y G, Ma E. Grain boundary effects on plastic deformation and fracture mechanisms in Cu nanowires: Molecular dynamics simulations. Phys Rev B, 2008, 77: 195429

Szlufarska I, Nakano A, Vashishta P. A cross over in mechanical response of nanocrystalline ceramics. Science, 2005, 309: 911

Chang W J. Molecular-dynamics study of mechanical properties of nanoscale copper with vacancies under static and cyclic loading. Microelectron Eng, 2003, 65: 239–246

Wu H A, Liu G R, Wang J S. Atomistic and continuum simulation on extension behaviour of single crystal with nano-holes. Modelling Simul Mater Sci Eng, 2004, 12: 225–233

Yang X H, Zhou T, Chen C Y. Effective elastic modulus and atomic stress concentration of single crystal nano-plate with void. Comput Mater Sci, 2007, 40: 51–56

Yang Y, Baker I. The influence of vacancy concentration on the mechanical behavior of Fe-40Al. Intermetallics, 1998, 6(3): 167–175

Pugno, Nicola M. Young’s modulus reduction of defective nanotubes. Appl Phys Lett, 2007, 90(4): 043106

Xu D S, Hu Q M, Lu J M, et al. Point defects and mechanical behaviour of titanium alloys and intermetallic compounds. J Phys: Confer Ser, 2006, 29: 220–227

Duan H L, Wang J, Huang Z P, et al. Size-dependent effective elastic constants of solids containing nanoinhomogeneities with interface stress. J Mech Phys Solids, 2005, 53(7): 1574–1596

Zhou T, Yang X Y, Chen C Y. Quasicontinuum simulation of single crystal nano-plate with a mixed-mode crack. Int J Solids Struct, 2009, 46(9): 1975–1980

Liang Y C, Chen J X, Chen M J, et al. Integrated md simulation of scratching and shearing of 3d nanostructure. Comput Mater Sci, 2008, 43: 1130–1140

Mishin Y, Mehl M J, Papaconstantopoulos D A, et al. Structural stability and lattice defects in copper: Ab initio, tight-binding, and embeddedatom calculations. Phys Rev B, 2001, 63: 224106

Kelchner C L, Plimpton S J, Hamilton J C. Dislocation nucleation and defect structure during surface indentation. Phys Rev B, 1998, 58: 11085

Pei Q X, Lu C, Lee H P, et al. Study of materials deformation in nanometric cutting by large-scale molecular dynamics simulations. Nanoscale Res Lett, 2009, 4: 444–451

Diao J, Gall K, Dunn M L, et al. Atomistic simulations of the yielding of gold nanowires. Acta Mater, 2006, 54: 643

Nisitani H, Noda N A. Stress concentration of a cylindrical bar with a V-shaped circumferential groove under torsion, tension or bending. Eng Fracture Mech, 1984, 20: 743–766

Gao H J, Ji B H, Jager I L, et al. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc Natl Acad Sci USA, 2003, 100: 5597–5600

Brandl C, Derlet P M, Swygenhoven H V. General-stacking-fault energies in highly strained metallic environments: Ab initio calculations. Phys Rev B, 2007, 76: 054124

Datta A, Waghmare U, Ramamurty U. Structure and stacking faults in layered Mg-Zn-Y alloys: A first-principles study. Acta Mater, 2008, 56(11): 2531–2539

Schall P, Cohen I, Weitz D A. visualizing dislocation nucleation by indenting collodial crystals. Nature, 2006, 440: 04557

Kobayashi M, Matsui T, Murakami Y. Mechanism of creation of compressive residual stress by shot peening. Int J Fatigue, 1998, 20(5): 351–357

Dahlman P, Gunnberg F, Jacobson M. The influence of rake angle, cutting feed and cutting depth on residual stresses in hard turning. J Mater Process Technol, 2004, 147(2): 181–184

Matsumoto Y, Hashimoto F, Lahoti G. Surface integrity generated by precision hard turning. Manuf Technol, 1999, 48(1): 59–62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Xiao, G., Chen, J. et al. Research on the influence of machining introduced sub-surface defects and residue stress upon the mechanical properties of single crystal copper. Sci. China Technol. Sci. 53, 3161–3167 (2010). https://doi.org/10.1007/s11431-010-4122-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-4122-1