Abstract

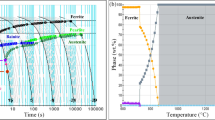

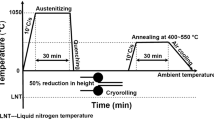

Ultrafine grained ferrite was obtained through tempering cold rolled martensite with an average grain size of 200–400 nm in a low carbon and a microalloyed steel. Thermal and mechanical stability of the two steels was studied. Due to the pinning effect of microalloyed precipitates on the movement of dislocations and grain boundaries, the recrystallization and grain growth rate were retarded, and the thermal stability of ultrafine grained microstructure was improved. The ultrafine grained ferritic steel was strengthened, but its strain hardening rate was reduced. It seems that the tiny carbide precipitates have no significant effect on work hardening rate. The ultrafine grained ferrite+martensite dual phase microstructure was obtained in the microalloyed steel through intercritically annealing cold rolled martensite. The resulting multiphase microstructure has a tensile strength higher than 1.0 GPa with a yield ratio lower than 0.7. Another type of multiphase microstructure with nanoscaled lath bainite+retained austenite was obtained through an isothermal heat treatment in low temperature bainite transformation region in high carbon steel. The tensile strength was as high as 1.64 GPa with a yield ratio of 0.84.

Similar content being viewed by others

References

Yuntian T Z, Terry C L. Observations and issues on mechanisms of grain refinement during ECAP process. Mater Sci Eng A, 2000, 291: 46–53

Horita Z, Fujinami T, Langdon T G. The potential for scaling ECAP-Effect of sample size on grain refinement and mechanical properties. Mater Sci Eng A, 2001, 318: 34–41

Saito Y, Tsuji N, Utsunomiya H, et al. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding(ARB) process. Scr Mater, 1998, 39(9): 1221–1227

Tsuji N, Saito Y, Utsunomiya H, et al. Ultra-fine grained bulk steel produced by accumulative roll-bonding (ARB) process. Scr Mater, 1999, 40(7): 795–800

Tsuji N, Ueji R, Minamino Y, et al. A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr Mater, 2002, 46: 305–310

Ueji R, Tsuji N, Minamino Y, et al. Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite. Acta Mater, 2002, 50: 4177–4189

Ueji R, Tsuji N, Minamino Y, et al. Effect of rolling reduction on ultrafine grained structure and mechanical properties of low-carbon steel thermomechanically processed from martensite starting structure. Sci Technol Adv Mater, 2004, 5: 153–162

Kitahara H, Ueji R, Tsuji N, et al. Crystallographic features of lath martensite in low-carbon steel. Acta Mater, 2006, 54: 1279–1283

Lan H F, Liu W J, Liu X H. Ultrafine ferrite grains produced by tempering cold-rolled martensite in low carbon and microalloyed steels. ISIJ Int, 2007, 47(11): 1652–1657

Lian J, Baudelet B, Nazarov A A. Model for the prediction of the mechanical behavior of nanocrystalline materials. Mater Sci Eng A, 1993, 172: 23–29

Lian J, Baudelet B. A modified Hall-Petch relationship for nanocrystalline materials. Nanostruc Mater, 1993, 2: 415–419

Valiev R Z, Ivanisenko Y V, Rauch E F, et al. Structure and deformation behavior of Armco iron subjected to severe plastic deformation. Acta Mater, 1996, 44(12): 4705–4712

Morris J W. The influnce of grain size on the mechanical properties of steel. Fundamental research of new generation steels. Foreign References Compilation of Fundamental Research of New Generation Steels (in Chinese). Beijing: China Metal Society, 2001. 163–170

Takaki S, Morris J W. The influnce of grain size on the mechanical properties of steel. fundamental research of new generation steels. Foreign References Compilation of Fundamental Research of New Generation Steels (in Chinese). Beijing: China Metal Society, 2001. 171–179

Fang X F, Dahl W. Strain hardening of steels at large strain deformation. Part 1: Relationshop between strain hardening and microstructures of b.c.c. steels. Mater Sci Eng A, 1995, 203: 14–25

Park K T, Lee C S, Shin D H. Strain hardenability of ultrafine grained low carbon steels processed by ECAP. Rev Adv Mater Sci, 2005, 10: 133–137

Bhadeshia H K D H. 52nd Hatfield memorial lecture: large chunks of very strong steel. Mater Sci Technol, 2005, 21(11): 1293–1302

Takahashi M, Bhadeshia H K D H. Model for transition from upper to lower bainite. Mater Sci Technol, 1990, 6: 592–603

Song H W, Shi B, Wang X F, et al. Characterization of a low carbon low alloy steel by nanoindentation (in Chinese). Acta Metall Sin, 2005, 41(3): 287–290

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Fundation of China (Grant No. 50634030)

Rights and permissions

About this article

Cite this article

Liu, X., Lan, H., Du, L. et al. High performance low cost steels with ultrafine grained and multi-phased microstructure. Sci. China Ser. E-Technol. Sci. 52, 2245–2254 (2009). https://doi.org/10.1007/s11431-009-0218-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0218-x