Abstract

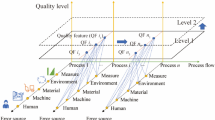

In multistage machining processes (MMPs), the final quality of a part is influenced by a series of machining processes, which are complex correlations. So it is necessary to research the rule of machining error propagation to ensure the machining quality. For this issue, a change management method of quality control nodes (i.e., QC-nodes) for machining error propagation is proposed. A new framework of QC-nodes is proposed including association analysis of quality attributes, quality closed-loop control, error tracing and error coordination optimization. And the weighted directed network is introduced to describe and analyze the correlativity among the machining processes. In order to establish the dynamic machining error propagation network (D-MEPN), QC-nodes are defined as the network nodes, and the correlation among the QC-nodes is mapped onto the network. Based on the network analysis, the dynamic characteristics of machining error propagation are explored. An adaptive control method based on the stability theory is introduced for error coordination optimization. At last, a simple example is used to verify the proposed method.

Similar content being viewed by others

References

Liu D Y, Jiang P Y, Zhang Y F. An e-quality control model for multistage machining processes of workpieces. Sci China Ser E-Tech Sci, 2008, 51(12): 2178–2194

Montgomery D C. Introduction to statistical quality control. In: 3rd ed. New York: Wiley, 1996

Luo Z B, Wang J S, Jia K, et al. Machining error flow model in manufacturing processes. Chin J Mech Eng, 1994, 30(1): 112–118

Zhang G X. A new diagnosis theory with two kinds of quality. Total Qual Manage & Business Excellence, 1990, 1(2): 249–258

Zhang G X. New type of quality control charts—cause-selecting control charts and a theory of diagnosis with control charts. In: Proceedings of the World Quality Congress’ 84. Brighton, England: Inst of Quality Assurance, 175–185

Wade M R, Woodall W H. A review and analysis of cause-selecting control charts. J Qual Tech, 1993, 25(3): 161–169

Camelio J, Hu S J, Ceglarek D. Modeling variation propagation of multi-station assembly systems with compliant parts. J Mech Des, 2003, 125(44): 673–681

Zhang L, Ni J, Lai X M. Dimensional errors of rollers in the stream of variation modeling in cold roll forming process of quadrate steel tube. Int J Adv Manuf Tech, 2008, 37(11–12): 1082–1092

Zhao J L, Guo W, Niu Z W, et al. Quality stability of multi-station assembly process based on stream of variation. Chin J Mech Eng, 2006, 42(11): 88–91

Jiang P Y. Research on implementing method and application for e-manufacturing systems (in Chinese). Comput Intrgr Manuf Syst-CIMS, 2003, 9(4): 253–259

Zhang Y F, Jiang P Y. A web-based e-formalization method for legacy CNC machine tools (in Chinese). Comput Intrgr Manuf Syst-CIMS, 2006, 10(4): 447–452

Cao G M, McHugh M. A systemic view of change management. Syst Prac Act Res, 2005, 18(5): 475–490

Stumm B. Change management in large-scale enterprise information systems. In: EDBT Workshops. Berlin: Springer, 2006. 86–96

Liu D Y, Jiang P Y. Modeling of machining error propagation network for multistage machining processes. Part II. LNAI 5315, 2008. 408–418

Jiang P Y, Liu D Y, Jia F. A change management framework: Managing the error variation in multi-stage machining processes. In: 7th World Congress on Intelligent Control and Automation. WCICA, 2008. 3660–3663

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (Grant No. 50875204) and the National Hi-Tech Research and Development Program of China (“863” Project) (Grant No. 2007AA00Z108)

Rights and permissions

About this article

Cite this article

Feng, J., Jiang, P. Method of change management based on dynamic machining error propagation. Sci. China Ser. E-Technol. Sci. 52, 1811–1820 (2009). https://doi.org/10.1007/s11431-009-0197-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0197-y