Abstract

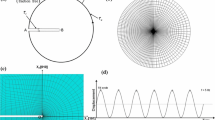

The tension necking of FCC copper single crystal specimen with a square cross section was analyzed under the slip deformation mechanism. The actual clamp manner of the specimen was modeled by setting correlative boundary condition, and the small angle deflection between tension loading axis and crystallography axis [100] was taken into account. The finite deformation numerical analysis of three-dimensional necking deformation for the specimen was performed by applying crystal plasticity theory associated with a numerical algorithm suggested by the first author. According to the comparison with experimental observation, the fact was confirmed that the numerical results could describe the loading elongation curve of the copper single crystal specimen under large strain tension reasonably, and the method could be used to investigate the necking characteristic in neck shape and the effect due to the small angle deflection. Further, the investigation into the influence of specimen cross-section shape on necking was also performed; the results on mechanical response and neck profile evolution obtained through modeling of cylindrical specimen were compared with those obtained with square cross-section specimen.

Similar content being viewed by others

References

Hill R, Rice J R. Constitutive analysis of elastic-plastic crystal at arbitrary strain. J Mech Phys Solids, 1972, 20: 401–13

Asaro R J, Rice J R. Strain localization in ductile single crystals. J Mech Phys Solids, 1977, 25: 309–338

Peirce D, Asaro R J, Needleman A. Material rate dependence and localized deformation in crystalline solids. Acta Metall, 1983, 31: 1951–1976

Kalidindi S R, Bronkhorst C A, Anand L. Crystallographic texture evolution in bulk deformation processing of FCC metals. J Mech Phys Solids, 1992, 40: 537–569

Maniatty A M, Dawson P R, Lee Y S. A time integration algorithm for elasto-viscoplastic cubic crystals applied to modeling polycrystalline deformation. Inter J Num Meth Engrg, 1992, 35: 1565–1588

Sarma G, Zacharia G. Integration algorithm for modeling the elastoviscoplastic response of polycrystalline materials. J Mech Phys Solids, 1999, 47: 1219–1238

Asaro R J, Needleman A. Texture development and strain hardening in rate dependent polycrystals. Acta Metall, 1985, 33: 923–953

Needleman A, Asaro R J, Lemonds J, et al. Finite element analysis of crystalline solids. Comp Methods Appl Mech Eng, 1985, 52: 689–708

Watanabe O, Zbib H M, Takenouchi E. Crystal plasticity: micro-shear banding in polycrystals using Voronoi tessellation. Int J Plas, 1998, 14: 771–788

Kuroda M, Tvergaard V. Shear band development predicted by a non-normality theory of plasticity and comparison to crystal plasticity predictions. Int J Solids Struct, 2001, 38: 8945–8960

Hutchinson J W. Elastic-plastic behavior of polycrystalline metals and composites. Phil Proc R Soc London, 1970, A318: 247–272

Zhang K S. Microscopic heterogeneity and macroscopic mechanical behavior of a polycrystalline material. Acta Sin Mech (in Chinese), 2004, 36: 714–723

Hutchinson J W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc Roy Soc Lond, 1976, 348A: 101–127

Peirce D, Shih C F, Needleman A. A tangent modulus method for rate dependent solids. Comput Struct, 1984, 18: 875–887

Zhang K S. A finite element algorithm for frystal viscoplastic finite deformation. Mech Sci Tech (in Chinese), 2001, 20(suppl.): 1–4

Xu Z M, Li L, Li J G, et al. Orientation and competitive growth of single crystal copper by continuous casing. J Synth Cryst (in Chinese), 1999, 28: 188–192

Hirth J P, Lothe J. Theory of Dislocations. 2nd ed. New York: John Wiley and Sons, 1982

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (Grant Nos. 10472092 and 10662001) and the Aviation Science Foundation of China (Grant No. 04C53027)

Rights and permissions

About this article

Cite this article

Zhang, K., Geng, X., Li, J. et al. On the tension necking of copper single crystal specimen under slip deformation mechanism. SCI CHINA SER E 50, 308–318 (2007). https://doi.org/10.1007/s11431-007-0038-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11431-007-0038-9