Abstract

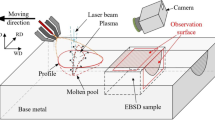

As a new direct metal prototyping technology, the hybrid plasma and laser deposition manufacturing (PLDM) is proposed in this paper. In order to figure out the characteristics of plasma arc beam and mould in the PLDM process of high temperature alloy, the high speed CCD camera is used to obtain the picture around the plasma arc. Afterwards the sketch of picture is clearly obtained. And the effect of laser parameter, such as average power, pulse width, pulse repetition frequency and the angle between laser beam and plasma arc beam on the plasma arc appearance, is studied experimentally. The results show that the modality of plasma arc beam is markedly influenced by laser beam. And the improvements of shape precision and surface state of the layer deposited by PLDM are confirmed.

Similar content being viewed by others

References

Xu, J., Yan, Y. N., Lu, W. et al., The analysis of trends on rapid prototyping, Aeronautical Manufacturing Technology, 2002, (11): 25–27.

Zhang, H. O., Wang, G. L., Luo, Y. H., Rapid hard tooling plasma spraying for injection molding and sheet metal forming, Thin Solid Films, 2001, 390: 7–11.

Allahverdi, M., Danforth, J. S. C. M., Processing of advanced electro ceramic components by fused deposition technique, Journal of the European Ceramic Society, 2001, 21: 1485–1490.

Junghoon, H., Kunwoo, Lee, Z. H., Hybrid rapid prototyping system using machining and deposition, Computer-Aided Design, 2001, 34: 741–754.

Zhang, H. O., The current situation and the trends on rapid tooling, Die and Mould Technology, 2000 (6): 84–89.

Muller, H., Sladojevic, J., Rapid tooling approaches for small lot production of sheet-metal parts, Journal of Material Processing Technology, 2001, 115: 97–103.

Wang, H. M., Research progress on laser surface modifications of metallic materials and laser rapid forming of high performance metallic components, Acta Aeronautica Etastronautica Sinca, 2002, 23(5): 473–478.

Bai, P. K., Shi, Y. H., Cheng, J. et al., Rapid manufacturing technology of 3D welding forming, Welding Technology, 1998 (6): 39–40.

Zhang, H., Xu, J., Wang, G., Fundamental study on plasma deposition manufacturing, Surface and Coating Technology, 2003, 171(1–3): 112–118.

Chen, Y. B., Chen, J., Li, L. Q. et al., Properties of arc and weld in laser-TIG hybrid process, Transactions of the China Welding Institution, 2003, 24(1): 55–56, 60.

Chen, Y. B., Li, L. Q., Chen, F. D., Effect of laser-supported combustion on laser-TIG hybrid heat source, Journal of Harbin Institute of Technology, 2003, 35(6): 695–697.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Qian, Y., Wang, G. et al. The characteristics of arc beam shaping in hybrid plasma and laser deposition manufacturing. SCI CHINA SER E 49, 238–247 (2006). https://doi.org/10.1007/s11431-006-0238-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-006-0238-8