Abstract

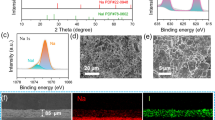

Efficient plating/stripping of Na metal is critical to stable operation of any rechargeable Na metal battery. However, it is often overlooked or misunderstood in electrochemical measurements using thick Na electrodes with large excess of Na reserves. Herein, we report two crucial aspects, which have generally been ignored in previous studies, in the development of more practical capacity-controlled Na metal electrodes that can be efficiently cycled at 100% depth. We find that common carbonate electrolytes induce severe side reaction and highly irreversible Na plating/stripping, whereas ether electrolytes without any additive support thick Na metal electrodes operating at a high average Coulombic efficiency of 99.6% for over 300 cycles. We further show that to realize such high efficiency in thin Na metal electrodes, it is necessary to ensure strong adhesion between the thin Na layer and the Cu current collector, which we solve by introducing an Au interlayer. The resulting transferable thin Na metal electrodes enable high-energy-density, high-efficiency and reasonably stable-cycling Na∥Na3V2(PO4)3 batteries.

Similar content being viewed by others

References

Pan H, Hu YS, Chen L. Energy Environ Sci, 2013, 6: 2338–2360

Kim SW, Seo DH, Ma X, Ceder G, Kang K. Adv Energy Mater, 2012, 2: 710–721

Hwang JY, Myung ST, Sun YK. Chem Soc Rev, 2017, 46: 3529–3614

Luo W, Shen F, Bommier C, Zhu H, Ji X, Hu L. Acc Chem Res, 2016, 49: 231–240

Zhao Y, Adair KR, Sun X. Energy Environ Sci, 2018, 11: 2673–2695

Lee B, Paek E, Mitlin D, Lee SW. Chem Rev, 2019, 119: 5416–5460

Shi Q, Zhong Y, Wu M, Wang H, Wang H. Angew Chem Int Ed, 2018, 57: 9069–9072

Seh ZW, Sun J, Sun Y, Cui Y. ACS Cent Sci, 2015, 1: 449–455

Choudhury S, Wei S, Ozhabes Y, Gunceler D, Zachman MJ, Tu Z, Shin JH, Nath P, Agrawal A, Kourkoutis LF, Arias TA, Archer LA. Nat Commun, 2017, 8: 898

Zhang Y, Zhong Y, Shi Q, Liang S, Wang H. J Phys Chem C, 2018, 122: 21462–21467

Chen S, Niu C, Lee H, Li Q, Yu L, Xu W, Zhang JG, Dufek EJ, Whittingham MS, Meng S, Xiao J, Liu J. Joule, 2019, 3: 1094–1105

Zhong Y, Xie Y, Hwang S, Wang Q, Cha JJ, Su D, Wang H. Angew Chem Int Ed, 2020, doi: https://doi.org/10.1002/anie.202004477

Zhang W, Wu Q, Huang J, Fan L, Shen Z, He Y, Feng Q, Zhu G, Lu Y. Adv Mater, 2020, 32: 2001740

Cohn AP, Muralidharan N, Carter R, Share K, Pint CL. Nano Lett, 2017, 17: 1296–1301

Tang S, Qiu Z, Wang XY, Gu Y, Zhang XG, Wang WW, Yan JW, Zheng MS, Dong QF, Mao BW. Nano Energy, 2018, 48: 101–106

Wang C, Wang H, Matios E, Hu X, Li W. Adv FunctMater, 2018, 28: 1802282

Lu K, Gao S, Li G, Kaelin J, Zhang Z, Cheng Y. ACS Mater Lett, 2019, 1: 303–309

Zhu M, Wang G, Liu X, Guo B, Xu G, Huang Z, Wu M, Liu HK, Dou SX, Wu C. Angew Chem Int Ed, 2020, 59: 6596–6600

Luo W, Lin CF, Zhao O, Noked M, Zhang Y, Rubloff GW, Hu L. Adv Energy Mater, 2017, 7: 1601526

Li P, Xu T, Ding P, Deng J, Zha C, Wu Y, Wang Y, Li Y. Energy Storage Mater, 2018, 15: 8–13

Zhao Y, Goncharova LV, Zhang Q, Kaghazchi P, Sun Q, Lushington A, Wang B, Li R, Sun X. Nano Lett, 2017, 17: 5653–5659

Zhu M, Li S, Li B, Gong Y, Du Z, Yang S. Sci Adv, 2019, 5: eaau6264

Zheng X, Fu H, Hu C, Xu H, Huang Y, Wen J, Sun H, Luo W, Huang Y. J Phys Chem Lett, 2019, 10: 707–714

Chi SS, Qi XG, Hu YS, Fan LZ. Adv Energy Mater, 2018, 8: 1702764

Zhang Y, Zhong Y, Liang S, Wang B, Chen X, Wang H. ACS Mater Lett, 2019, 1: 254–259

Rodriguez R, Loeffler KE, Nathan SS, Sheavly JK, Dolocan A, Heller A, Mullins CB. ACS Energy Lett, 2017, 2: 2051–2057

Zhang XQ, Cheng XB, Chen X, Yan C, Zhang Q. Adv Funct Mater, 2017, 27: 1605989

Deng Y, Zheng J, Warren A, Yin J, Choudhury S, Biswal P, Zhang D, Archer LA. Adv Energy Mater, 2019, 9: 1901651

Fang C, Li J, Zhang M, Zhang Y, Yang F, Lee JZ, Lee MH, Alvarado J, Schroeder MA, Yang Y, Lu B, Williams N, Ceja M, Yang L, Cai M, Gu J, Xu K, Wang X, Meng YS. Nature, 2019, 572: 511–515

Gu Y, Wang WW, Li YJ, Wu QH, Tang S, Yan JW, Zheng MS, Wu DY, Fan CH, Hu WQ, Chen ZB, Fang Y, Zhang QH, Dong QF, Mao BW. Nat Commun, 2018, 9: 1339

Tang S, Zhang YY, Zhang XG, Li JT, Wang XY, Yan JW, Wu DY, Zheng MS, Dong QF, Mao BW. Adv Mater, 2019, 31: 1807495

Louli AJ, Genovese M, Weber R, Hames SG, Logan ER, Dahn JR. J Electrochem Soc, 2019, 166: A1291–A1299

Weber R, Genovese M, Louli AJ, Hames S, Martin C, Hill IG, Dahn JR. Nat Energy, 2019, 4: 683–689

Yin X, Tang W, Jung ID, Phua KC, Adams S, Lee SW, Zheng GW. Nano Energy, 2018, 50: 659–664

Acknowledgements

This work was supported by the U.S. National Science Foundation (CBET-1903342). Zhang Y acknowledges an exchange graduate student scholarship from the China Scholarship Council. Zhong Y acknowledges the Link Foundation Energy Fellowship. Wang H acknowledges the Sloan Research Fellowship. We thank Bingchen Deng in the Department of Electrical Engineering at Yale University for help with Au deposition on Cu. We also thank Dr. Xinxin Cao at Central South University for providing the Na3V2(PO4)3 material.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Supporting Information

Rights and permissions

About this article

Cite this article

Zhang, Y., Shi, Q., Zhong, Y. et al. Intrinsically high efficiency sodium metal anode. Sci. China Chem. 63, 1557–1562 (2020). https://doi.org/10.1007/s11426-020-9808-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-020-9808-6