Abstract

Many planar 2-DOF translational parallel robots which were invented for the simple industrial tasks are easy to suffer the problem of the poor intrinsic stiffness along the normal direction to the plane of motion. To solve this problem, the passive limbs can be introduced into the design of parallel mechanisms to increase the stiffness and stability of the robots. Besides the capability of stiffness increasing, the passive limbs can also provide constraints, generate decoupled configuration, bear full or partial weights and/or payloads, liberate constraints from the actuations, and even decrease the required actuating forces of active limbs. However, there is still no systematic study on the utilization of passive limbs to date. In this paper, the stiffness–robust 2-DOF translation parallel robots with passive limbs are investigated in terms of type synthesis. Based on the distribution of wrench system among the active limbs and passive limbs, a full-scale criterion is developed for effectively and efficiently synthesizing all kinds of 2-DOF translational parallel mechanisms with one or more passive limbs. All 14 types of the 2-DOF translational parallel mechanisms with passive limbs are synthesized and exemplified through kinematic diagrams. A qualitative stiffness index is purposed to evaluate the stiffness performance of all of the synthesized configurations directly and rapidly. Finally, an optimized configuration of stiffness-enhanced 2T PM is derived and exhibits the best stiffness performance.

Similar content being viewed by others

1 Introduction

Many 2-DOF translational (2T) parallel mechanisms (PMs) were invented for the simple industrial tasks such as pick-and-place operation [1,2,3]. In particular, for industrial robots where the primary target is the precise manipulation of a technological tool, the manipulator stiffness defines the positioning errors due to the external loading arising during the workpiece processing [4]. And the industrial pick-and-place applications are also intended for simple but fast manipulations. It requires the reduction in the weight of the robots to achieve high acceleration. Frankly speaking, the primary planar 2T parallel mechanism is easy to suffer the problem of the poor intrinsic stiffness along the normal to the plane of motion [5, 6]. This problem may cause deformations of the robot by an external force or torque applied to the end effector. The main target of this paper is to design a stiffness-directed (norm to plane of motion)-enhanced 2T parallel robot.

To enhance the stiffness of norm direction of the 2T parallel robot, the hybrid legs were introduced into the design to transform the configuration from planar one to spatial one [6,7,8]. However, the hybrid architectures introduced overconstraints and made the configuration complicated. No general type synthesis has been proposed for the hybrid structures that make them relatively difficult to be synthesized or derived. Also the hybrid configurations are space-consumed that was difficult to be implemented in space-limited circumstance. Surprisingly, the introduction of passive limbs (PLs) may solve all the aforementioned problems for the 2T PMs simultaneously.

PL is an auxiliary limb that occasionally introduced into the design of PMs for various purposes. Indeed, PLs can be utilized more often in PM designs if necessary as they may liberate the constraints from the active limbs, generate decoupled configuration, bear full or partial weights and/or payloads, decrease the required actuating forces of active limbs, and/or even increase the stiffness and accuracy of the whole system. For example, a fully decoupled 2-DOF parallel wrist was introduced involving a passive universal (U) joint that provides a fixed rotation center for the moving platform [9]. A passive limb consisted of a spherical (S) joint was introduced for a 3-SPS parallel manipulator design to define a rotation center [10]. Not only does the passive spherical joint limb carry the full/partial weights (depends on whether or not the passive joints locates on the center of mass of the moving platform), it also decrease the required actuating forces by liberating the effective inertial forces from the gravity forces [11] and reducing the friction originally existed in the ALs. A family of N-DOF PMs with a passive constraining leg was also proposed by Zhang and Gosselin [12, 13]. The kinetostatic analysis proved the positive effect to the structural rigidity. In particular, the 3-DOF Tricept robot, one of the most successful commercial robots, contained a passive constraining leg that permitted a separation of the function of constraint from that of actuation [14, 15]. Hence, a systematic study on the PMs with one or more PLs is necessary for the structural design of the stiffness-directed-enhanced 2T parallel robots.

However, the general type synthesis of PMs with PLs has not been well summarized. Though PMs have been and are being used in a wide variety of applications such as motion simulators and parallel manipulators and even micro- and nano-manipulators [16], from the well-known Gough–Stewart platform to the Delta robot to the Agile Eye and many other designs, PMs have been largely synthesized using intuition and ingenuity. To invent new PMs in an operational way, several type synthesis methods have been published in the last decade based on various mathematical tools, such as screw theory [16, 17], Lie Group and Lie algebra [18, 19], linear transformation [20], position and orientation characteristics equation [21], and generalized function (\(\hbox {G}_{\mathrm{F}})\) set theory [22]. Nevertheless, attentions were mostly paid to those PMs that are composed of active limbs (ALs).

Therefore, 2T PMs with PLs are investigated systematically in terms of topological design. Based on the distribution of constraints among ALs and PLs, a type synthesis method is presented and a family of novel 2T PMs with PLs is proposed. Although some types of 2T PMs with one PL have been synthesized [20], much more kinematic structures of the PLs can be developed. Since the variety performances brought by the PLs come from their unique configurations, the work that reported in this paper aims to develop an effective and efficient approach that is capable of synthesizing all kinds of 2T PMs with PLs.

The primary goal of this paper is to design the stiffness-directed enhanced 2T PMs. Therefore, after a number of configurations being synthesized, the stiffness analysis needs to be performed to evaluate the performance of the newly designed PMs. The state of art of the stiffness analysis approach may be roughly divided into three main groups: the finite element analysis, the matrix structural analysis, and the virtual joint method [23]. They usually analyze the stiffness of a mechanism based on its pre-derived Jacobian and detailed scale of each components. With the increase in the limbs in the configurations of the stiffness-directed-enhanced 2T PM, even the simplest conventional stiffness modeling approaches are too slow and too high-computation-expended to efficiently evaluate the stiffness performance of the new configurations. In a word, there is no stiffness analysis that can directly evaluate the stiffness of a configuration without given the size/scale parameters of its components. Therefore, the rapid stiffness estimation is presented to evaluate each configuration directly.

The industrial pick-and-place applications are also intended for fast manipulations [6]. Consequently, the weight of a manipulator must also be taken into account in the comprehensive evaluations of a configuration. A simple stiffness over mass index, so-called configuration stiffness efficiency (denoted as \(\hbox {E}_{\mathrm{CS}})\), is therefore purposed to further evaluate the composite performance of the stiffness-directed-enhanced 2T parallel robots.

2 Configuration stiffness qualitative estimation

The robot stiffness analysis evaluates the manipulator resistance to the deformations caused by an external force or torque applied to the end effector [24]. Numerically, this property is usually defined through the stiffness matrix, which is incorporated in a linear relation between the translational/rotational displacement and static forces/torques causing this transition [4]. The existing approaches for the manipulator stiffness modeling may be roughly divided into three main groups: the finite element analysis (FEA), the matrix structural analysis (MSA), and the virtual joint method (VJM) [23]. The most accurate approach is the FEA-based stiffness modeling [25,26,27]. However, the FEA model has to be remeshed over and over again because of the motion of the components. The MSA [28] operates with rather large elements—3D flexible beams that are presented in the manipulator structure that could reduce the computational expenses in parametric stiffness analysis. It usually makes this approach be applied at the final design stage. On the contrary, the VJM technique is widely used at the pre-design stage [4]. The VJM method is based on the extension of the traditional rigid model by adding the virtual joints (localized springs), which describes the elastic deformations of the links, joints, and actuators [4, 23, 29].

All these methods establish the stiffness model based on the accurate size/scale parameters of the components of a configuration. Sometimes, the Jacobian that is derived from the kinematic analysis is taken into account too. Obviously, the state of art of the stiffness analysis is performed at the parameter design stage instead of the conceptual design stage. With the increase in the limbs in the configurations of the stiffness-directed-enhanced 2T PM, the conventional stiffness modeling approaches are too slow and too high-computation-expended to evaluate the stiffness performances of so much newly synthesized configurations. In this paper, a new fast stiffness evaluation method is developed for the conceptual design stage that can estimate the stiffness of a configuration directly and efficiently according the configurations.

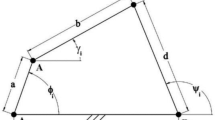

The direct configuration stiffness estimation is proposed based on a few presuppositions. The equivalent stiffness \(k_{z}\) should be introduced to facilitate the estimation since the aim direction of the stiffness enhancing is the along z-axis direction (norm to the plane of motion). Because the desired direction of stiffness is not along any direction of the motions, the stiffness difference of a configuration at different positions and orientations could be ignored to simplify analysis. The stiffness of actuation could be ignored too. The Jacobian and the kinematic analysis could be skipped in the stiffness estimation consequently. The configuration stiffness is therefore mainly contributed from the structure constraint. The limbs which provide corresponding structure constraint are called supportive limbs. The dimensions of each type of components should be defined equally. For an example, the length of every linkage applied in the configuration is l. Therefore, the stiffness influenced by dimensions can be eliminated. The stiffness estimation could be focused on the configuration consequently.

The whole process of the configuration stiffness estimation, as shown in Fig. 1, can be described as follows. The first step is to define the theoretical dimension of each component of the supportive limbs. Then the second step comes to calculate the axial deformation or bending deflection of the components and derive the resultant deformation of each limb. And then derive their equivalent stiffness, respectively, at the third step. Finally the configuration stiffness equals to the sum of the equivalent stiffness of the supportive limbs.

The existing stiffness models are all based on the size/scale parameter of components. Therefore, these approaches cannot estimate the configuration stiffness directly. By defining the qualitative components stiffness which derived from the theoretical dimensions, at the beginning of the stiffness analysis, we can focus our attentions on evaluating the stiffness of the structure/architecture of the mechanism itself. Without loss of generality, the rigidities of the platform, carriage, and base are assumed much higher than those of the other components. The deformation of each limb mainly comes from the deflection/deformation by the bending of the links of the limbs that provides z-axis constraint force. According to the mechanics of materials, the deformation \(\delta _{i,j}\) of a cantilever j of limb i, which is commonly found in stiffness analysis for 2T PM, under the external force F, is:

If the components are serially connected, the resultant deformation of a limb equals to the sum of each \(\delta _{i,j}\). Then the resultant rigidity of the limb i is:

If the components are connected in parallel, the equivalent stiffness of a limb can be added directly:

The estimated configuration stiffness can also be derived by adding the equivalent stiffness of each limb directly since the limbs are connected to the platform in parallel:

Based on the stiffness estimation above, it is obvious to conclude that the more supportive limbs a configuration consists of, the better stiffness performance it owns. However, more limbs increase the inertia of the manipulator that may decrease its mobility performance. A simple stiffness over mass index is therefore proposed to evaluate the composite performance of the stiffness-directed-enhanced 2T parallel robots. It is defined by the configuration stiffness over the total mass of the movable components. This comprehensive evaluation is therefore so-called configuration stiffness efficiency index (\(\hbox {E}_{CS})\) which is defined as follows:

3 Type synthesis of 2T PMs with PLs using independent constraints

To design a stiffness-enhanced 2T PM by using PL, the first thing is the proposition of the general type synthesis for 2T PMs with PLs. To facilitate the discussion, the two orthogonal translation directions are used to define the x-axis and y-axis of a Cartesian coordinate system. The wrench system of a 2T PM is then a 4-system [16] which consists of z-axis constraining force (CF), and x-axis, y-axis, as well as z-axis constraining couples (CCs). Then all of the wrenches are distributed into both active limbs and passive limbs, respectively. The kinematic chains of each limb can be constructed according to the its own wrench [30, 31]. A configuration is finally conducted by assembling all of the synthesized limbs.

To seek all kinds of stiffness-enhanced 2T PM, this section demonstrates 14 types of 2T PMs with PLs. Each kind of newly synthesized 2T PM has enhanced the normal-direction stiffness more or less. To illustrate the constraints clearly and intuitively, each limb in the following PMs is supposed to be composed by revolute (R) joints, spherical joint, and prismatic joint. The constraints are denoted by the symbols as shown in Table 1 in all of the configuration figures below.

3.1 Type synthesis of 2T PMs with Zero constraint from ALs

This category of 2T PMs is such a kind of PMs whose ALs provide no constraint. This means all constraints are provided by PLs. The wrench distributions of each configuration are listed in Table 2.

For a 3-limb-PM with none constraint from ALs, the only PL has to provide four-dimensional constraints. An example of the synthesized PM is shown in Fig. 2.

This type of PMs represents the most common PMs that contain one passive constraining limb. The biggest advantage of this kind of PMs is the simple and straightforward design process of the configuration.

There are two kinds of 4-limb-PMs with two PLs. The wrench system of the first kind of PM corresponds to the second row of the wrench distribution of Table 2, as shown in Fig. 3(a–d). Their wrench system consists of three constraints from PL1 and one additional independent constraint from PL2. The second kind of PMs is shown in Fig. 4 whose wrench system consists of two constraints from PL1 and two different constraints from PL2.

As shown in Fig. 3, the four mechanisms are good examples that illustrate all four possible combinations of constraints which are equivalent in the type synthesis. The other possible combinations of constraints can be enumerated by the same way that will not be listed here for readability. Hence, a total of 22 different configurations could be discovered completely that identically consist of three constraints from PL1 and one additional independent constraint from PL2. This will be detailed discussed by the end of this section.

Afterward, the examples of 5-limb-PM and 6-limb-PM with zero constraints from ALs are illustrated in Figs. 5 and 6. All the wrenches from limbs are independent.

3.2 Type synthesis of 2T PMs with one constraint from ALs

This category of 2T PMs is a kind of PMs whose ALs provide one constraint. Their wrench distributions are demonstrated in Table 3.

Because the only one constraint contributed by AL1 is a CC along z-axis, the AL1 can be constructed by the kinematic chain of PPPRxRy, or some other kinematic chains with the identical wrench system. The other AL remains a 6-DOF with a UPS kinematical structure. Three configurations of 2T PM without redundant constraints can be synthesized as shown in Figs. 7, 8, and 9.

3.3 Type synthesis of 2T PMs with two constraints from ALs

This category of 2T PMs is a kind of PMs which ALs provide two independent constraints. Their wrench distributions are listed in Table 4.

Four configurations of 2T PM without redundant constraints can be synthesized and illustrated in Figs. 10, 11, 12, and 13. Since the number of linearly independent wrenches from ALs is two, there are two subclasses of wrench distribution for ALs. For one subclass, each AL provides one independent constraints. For the other, there is only one constraining AL which provides both two independent constraints.

3.4 Type synthesis of 2T PMs with three constraints from ALs

The ALs of this category of 2-DOF PMs provide three independent constraints and only one PL. The wrench system are demonstrated in Table 5.

Two examples are given as the result of type synthesis shown in Figs. 14 and 15.

3.5 Modified decomposition of wrench system

After enumerating 14 types of 2T PM with PLs, the wrench distribution rules can be summarized in this subsection. The conventional decomposition of the wrench system allocates the wrenches among ALs [16]. By introducing PLs, this paper modifies the type synthesis method and the wrenches are distributed among ALs and PLs. It can also be found that the basic function of the PLs is to provide independent wrench to the wrench system of a 2T PM. At the same time, the ALs can provide no structural constraints at all. The distribution of the independent wrenches among ALs and PLs of the 14 prior configurations is listed in Table 6, while six basic rules can be summarized consequently:

-

(a)

Suppose, without loss of generality, the number of wrenches provides from AL1 is greater than AL2, and similarly for PLs as \(\hbox {PL}1\ge \hbox {PL}2\ge \hbox {PL}3\ge \hbox {PL}4\).

-

(b)

If the number of the wrenches of an AL equals to zero, it means that the AL is a 6-DOF limb providing no constraints to the PM.

-

(c)

If the wrenches of a PL is denoted as “–,” it implies that the PM has no corresponding PL.

-

(d)

In this table, the listed wrenches provided by AL2, or PL2, PL3, and PL4 only represent the independent wrenches comparing to AL1 or PL1, not including the possible same wrenches as other limbs, vice versa.

-

(e)

The last column of Table 6 denotes the number of all possible combinations of independent wrenches. Some cases of the calculation of the constraint combinations are enumerated in the following Sect. 3.6.

-

(f)

The wrench distribution enumerated in Table 6 is an example. It is one of the simplest combinations with independent constraints instead of redundant ones. Also the wrench type setting for ALs and PLs is exchangeable. Another example is given to illustrate a complete combination of wrenches in Sect. 3.6.

3.6 Combinations of constraints

Table 6 presents a complete record of total 14 types of the independent wrenches distribution among the ALs and PLs. But it only enumerated one of the simplest combinations of the wrenches without redundant wrenches. Indeed, AL2 or each PL may contain some additional/overlapping/dependent wrenches same as that from other limbs besides its own independent wrenches. Such introduction of dependent wrenches leads to redundant constraints, i.e., overconstraints [22]. That means the number of overconstraints can be designated according to the design requirement through proper arrangement of additional wrenches in the concept design stage.

An example is given here to illustrate the complete combinations of independent and dependent wrenches for designated distribution of the number of constraints among different limbs. As shown in Table 7, all the possible combinations of the constraints can be found that are identical to the distribution corresponding to the case of the second row of Table 6. Firstly, four kinds of wrenches combination of PL1 are calculated using formula \(C_{4}^{3}\), according to rule (f). \(\hbox {C}_{\mathrm{j}}^{\mathrm{i}}\) represents the number of combinations which can derived by choosing i objects from total j candidates. The expression of \(\hbox {C}_{\mathrm{j}}^{\mathrm{i}}\) can be defined as follows:

With respect to the PL1, one or two redundant constraints can be allocated to PL2 according to rules (d) and (e). Finally, a total of 22 possible combinations of the constraints can be listed for the type synthesis.

The detailed process of the discovery of all 22 possible combinations can be described as follows. After finding the four kinds of combinations of PL1, there is only one remaining independent wrench for PL2. This process could be calculated by \(C_{1}^{1}\) in Eq. (7). Three subclasses of the wrenches of PL2, \(\textcircled {1}\)PL2, \(\textcircled {2}\)PL2, and \(\textcircled {3}\)PL2 are discovered according to the number of redundant constraints which come from the rule (d). Specifically, if there is no redundant constraint in PL2, only one possible \(\textcircled {1}\)PL2 generated from \(C_{3}^{0}\). If there is only one redundant constraint in PL2, three different \(\textcircled {2}\)PL2 are generated by choosing one existing constraints from the three constraints of PL1, calculated in formula \(C_{3}^{1}\). If there are two redundant constraints in PL2, three different \(\textcircled {3}\)PL2 are generated by choosing two existing constraints, calculated through formula \(C_{3}^{2}\). There is an interesting fact that PL2 will be the same as PL1 when it provides the same number of constraints as PL1 does. To avoid repeating, the third subclass of PL2 needs to be divided by two. Moreover, there is no PL2 which is able to contain all three redundant constraints of PL1 according to the rule (a). Finally, the 22 different combinations of the constraints can be calculated using the following combination formula (7):

Several PMs corresponding to Table 7 will be illustrated with configuration figures in Sect. 3.1

Another aspect of rule (d) works when the following situation occurs. For an example, the distribution corresponding to the sixth row of Table 6 has 16 combinations of constraints according to rule (d). Although the number of independent constraints provided from AL2 is zero, the actual constraints of AL2 may be the same as that of AL1. Similarly, the actual wrench system of PL1 may include an overlapping constraint of AL1. Therefore, combinations of constraints which are identical to the wrench system of the sixth row of Table 6 are enlarged to a total of 16 combinations enumerated in Table 8 and calculated through Eq. (8):

The most complicated situation occurs when the combinations are calculated for the distributions which are identical to the 11th row of Table 6. There are 384 different kinds of combinations of constraints found by Eq. (9). The AL2, PL1, and PL2 may contain zero, one or two overlapping constraints of AL1. Since the number of independent constraint provided from PL1 is equal to that from PL2, there is no need to distinct which PL is PL1.

From those discussions above, the whole wrench distributions can be determined according to the proposed modified decomposition of wrench system over both ALs and PLs. The foundation of type synthesis of PMs with PLs has been established systematically.

4 Rough stiffness efficiency evaluation of 14 types 2T PMs

In previous sections, the basic idea of the type synthesis for 2T PMs with PLs is exemplified and detailed using some ideal topologies with independent constraints and fundamental joints. According to Sect. 2, the stiffness estimation of configurations is based on the bending stiffness of each supportive limb. At the same time, the total movable mass of a parallel robot must be taken into account in the comprehensive evaluation. To fairly compare the stiffness efficiency of all the 14 types of configurations, the parameter of each component, such as bending stiffness, length, and mass, is set equally. Since all of the configurations synthesized above are non-overconstrained mechanism, the resultant stiffness along normal direction of every configuration equals to 1, the stiffness efficiency is then actually depended on the sum of movable mass, as shown in Table 9. Consequently, the configurations that apply 3-limb structure exhibit the better stiffness performance than all the other configurations. There are 6 optional types of configurations, so-called 6 candidates, which can be applied in design of the stiffness-enhanced 2T parallel robots.

5 Optimized configurations with higher stiffness performance

5.1 Configuration optimization process

The real pick-and-place parallel robot always demands higher acceleration for manipulations and stiffer structure for control accuracy. By replacement with limbs of equivalent independent constraints, introduction of overconstraints, or even utilization of parallel constraint forces instead of couples properly, more practical and higher-performed designs of the 2T PMs can be achieved.

For example, the UPS&PPPU&PPR candidate configuration was optimized to become a PPaU-PSS-RRR mechanism as shown in Fig. 16. The PPPU kinematic chain (KC) of AL1 was optimized as a PPaU (Pa stands for parallelogram kinematic pair which generate translational motion with a circular trajectory) architecture. For one thing, the introduction of z-axis overconstraint force into other limbs improves the resultant stiffness by separating the external force and decreasing the deformation of each supportive limb. For another thing, the PPa KC enhanced the z-axis stiffness by introducing parallelogram structure to resist the deformation. The last but not the least, the UPS limb were replaced by a PSS limb in order to install the actuation (P kinematic pair is most likely being actuated) at the base. Therefore, the total weight of moving parts could be reduced a lot. Similarly, the PPR limb was replaced by RRR limb which possess the same workspace but half mass when it compares with the PPR structure as shown in Fig. 16.

According to the three limb optimization approaches above, the limbs implemented in 2T PM were redesigned. The parameter of each component, such as material, moment of inertia of the cross section (the section of every linkage kept constant), length, and mass, was equally set to keep the comparison fair. The guide should be installed on the basement and seemed as a rigid body. The equivalent theoretical stiffness of each optimized limb that is applied in the synthesis of the stiffness-enhanced 2T parallel robots was then derived and listed in the following Table 10 to demonstrate the improvement of stiffness performance.

5.2 Optimized 2T PMs using stiffer limbs

After replacing the optimized limbs, the redesigned aforementioned 6 candidate types of the stiffness-enhanced 2T PMs were synthesized.

For the 2T PM shown in Fig. 1, a new design was attained as shown in Fig. 17 by replacing the PP passive limb with a PPa structure that keeps the same kinematic constraints. In this design, the original two UPS-type ALs were substituted by two PSS limbs in order to locate the linear actuators on the base. Therefore, the total movable mass of the redesigned 2T PM weight was much less than before (Table 11).

The second candidate 2T PM, shown in Fig. 7, had already been redesigned and been shown in Fig. 16. The third/sixth candidate that was originally illustrated in Fig.9/14 obtained the same configuration as shown in Fig. 16 in redesign process.

The fourth candidate 2T PM that was originally shown in Fig. 11 experienced a large modification. The redesigned 2T PM, shown in Fig. 18, consisted of three identical PPaU limbs. The z-axis overconstraint was designed into the ALs, respectively. The PPaU KC independently contributes a z-axis CF and a z-axis CC to the wrench system. As mentioned before, two parallel CFs make up a CC forming a 2-system. Therefore, when three PPaU limbs are assembled on each side of a triangle, two independent CCs are composed to the wrench system of the mechanism. Consequently, this configuration owns an isotropic kinematic and dynamic performance. What’s more, the entire architecture of this 2T PM is extremely rigid in the direction perpendicular to the moving plane.

Otherwise, the fifth candidate 2T PM that was originally shown in Fig. 14 experienced a trivial modification. The redesigned 2T PM, shown in Fig. 19, consisted of two PRS KCs and one PRRR limb. The PRS architecture individually contributes one z-axis constraint force to the wrench system, while two parallel CFs that will make up a constraint couple to form a 2-system. Therefore, two PRS-type ALs each provide one independent constraint to the wrench system of the mechanism. Then a PRRR-type PL provides the remaining two independent CCs for the wrench system.

5.3 Stiffness performance evaluation of the optimized configurations

Given the standard stiffness performance of each type of limb, the resultant stiffness can be derived by the external force over the resultant deformation. Notice that the external force is averagely borne by each supportive limb, the actual deflection of each limb will be less or equal to the magnitude listed in Table 11. Taken the movable mass of each limb into account, the stiffness efficiency of all optional stiffness-enhanced 2T PM can be fairly evaluated.

6 Conclusion

The introduction of passive limbs into the design of parallel mechanisms provides one more option for the designers to enhance the particular-direction stiffness of a 2T parallel robot. To fast evaluate the stiffness performance of a configuration, the configuration stiffness estimation and stiffness efficiency index were proposed. This paper also investigated the 2-DOF translational parallel mechanisms with passive limbs in terms of type synthesis. Based on the distribution of wrench system among the ALs and PLs, an effective and efficient type synthesis method was presented. All the 14 types of 2T PM with one or more passive constraining limbs were enumerated. Meanwhile, several optional stiffness-enhanced 2T PMs with one passive constraining limb are selected through rough stiffness efficiency evaluation. The candidate configurations were then optimized by three limb optimization approaches: introduction of overconstraints, using stiffer structures and the reduction in the weights of movable parts. After performing the rapid stiffness estimation for each optional configuration, the 3PPaU PM exhibited the best stiffness efficiency in design of stiffness-enhanced 2T parallel robot. What’s more, the proposal of configuration estimation largely reduced the cost of stiffness analysis through the limb stiffness equivalent model. Tens of hours were saved from the endless remeshing of FEA elements, dimension design of components and kinematic analysis.

Abbreviations

- 2T:

-

2 degree of freedom translational

- PM:

-

Parallel mechanism

- PL:

-

Passive limb

- AL:

-

Active limb

- KC:

-

Kinematic chain

- U:

-

Universal joint

- P:

-

Prismatic joint

- R:

-

Revolute joint

- S:

-

Spherical joint

- Pa:

-

Parallelogram kinematic pair

- FEA:

-

Finite element analysis

- MSA:

-

Matrix structural analysis

- VJM:

-

Virtual joint method

- \(\hbox {E}_{\mathrm{CS}}\) :

-

Configuration stiffness efficiency index

- CF:

-

Constraining force

- CC:

-

Constraining couple

References

Brogårdh T, Smede J (2002) Device for relative movement of two elements. US

Chung YH, Lee JW (2001) Design of a new 2 DOF parallel mechanism. In: IEEE/ASME International Conference on Advanced Intelligent Mechatronics Proceedings 2001

Huang T, et al. (2006) Planar parallel robot mechanism with two translational degrees of freedom. US

Pashkevich A, Klimchik A, Chablat D (2011) Enhanced stiffness modeling of manipulators with passive joints. Mech Mach Theory 46(5):662–679

Peng B, et al. (2009) A novel high rigid 2-DOF parallel translating robot. In: International conference on intelligent computation technology and automation

Germain C, et al. (2011) IRSBot-2: a novel two-dof parallel robot for high-speed operations. In: ASME 2011 international design engineering technical conferences and computers and information in engineering conference

Company O et al (2011) Par2: a spatial mechanism for fast planar two-degree-of-freedom pick-and-place applications. Meccanica 46(1):10

Nurahmi L, Caro SP, Briot SB (2013) Type synthesis of two DOF translational parallel manipulators with hybrid legs. In: Computational Kinematics. Barcelona, Spain

Carricato M, Parenti-Castelli V (2004) A novel fully decoupled two-degrees-of-freedom parallel wrist. Int J Robot Res 23(6):661–667

Alici G, Shirinzadeh B (2004) Topology optimisation and singularity analysis of a 3-SPS parallel manipulator with a passive constraining spherical joint. Mech Mach Theory 39(2):215–235

Hirose S (1984) A study of design and control of a quadruped walking vehicle. Int J Robot Res 3(2):113–133

Zhang D, Gosselin CM (2002) Kinetostatic modeling of N-DOF parallel mechanisms with a passive constraining leg and prismatic actuators. J Mech Des 123(3):375–381

Zhang D, Gosselin CM (2002) Kinetostatic modeling of parallel mechanisms with a passive constraining leg and revolute actuators. Mech Mach Theory 37(6):599–617

Joshi SA, Tsai LW (2002) The kinematics of a class of 3-DOF 4-legged parallel manipulators. J Mech Design 125(1):325–334

Siciliano B (1999) The Tricept robot: inverse kinematics, manipulability analysis and closed-loop direct kinematics algorithm. Robotica 17:437–445

Kong X, Gosselin C (2007) Type synthesis of parallel mechanisms. Springer, Berlin Heidelberg

Stawell Ball R (1900) Scientific books: a treatise on the theory of screws. Science 12:1001–1003

Murray RM, et al. (1994) A mathematical introduction to robotic manipulation. CRC Press

Selig JM (2005) Geometric fundamentals of robotics. Springer, New York

Gogu G (2009) Structural synthesis of parallel robots. Springer, Netherlands

Yang T (2004) Topology structure design of robot mechanisms. Chinese Machine Press, Beijing

Gao F, Yang J, Ge QJ (2011) Type synthesis of parallel mechanisms having the second class G(F) sets and two dimensional rotations. J Mech Robot 3(1):895–902

Huang T, Zhao X, Whitehouse DJ (2002) Stiffness estimation of a tripod-based parallel kinematic machine. IEEE Trans Robot Autom 18(1):50–58

Duffy J (1996) Statics and kinematics with applications to robotics. Cambridge University Press, Cambridge

Hu X (2007) Finite element analysis of a six-component force sensor for the trans-femoral prosthesis. Springer, Berlin

Piras G, Cleghorn WL, Mills JK (2005) Dynamic finite-element analysis of a planar high-speed, high-precision parallel manipulator with flexible links. Mech Mach Theory 40(7):849–862

Zhu DC et al (2012) Research of the Stiffness and structure design for 2RPU-2SPS whole compliant parallel manipulator. J Jiangxi Univ Sci Technol 33(5):44–50

Deblaise D, Hernot X, Maurine P (2006) A systematic analytical method for PKM stiffness matrix calculation. In: IEEE International conference on robotics and automation

Pinto C et al (2010) A methodology for static stiffness mapping in lower mobility parallel manipulators with decoupled motions. Robotica 28(5):719–735

Yu J et al (2011) Screw Theory based methodology for the deterministic type synthesis of flexure mechanisms. J Mech Robot 3(3):1194–1204

Yu JJ, et al. (2011) Mobility and singularity analysis of a class of 2-DOF rotational parallel mechanisms using a visual graphic approach. In: ASME 2011 international design engineering technical conferences and computers and information in engineering conference

Acknowledgements

The author thanks the partial financial supports under the projects from the National Natural Science Foundation of China (Grant Nos. 51275284, 51323005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, W., Guo, W. Structural design of a novel family of 2-DOF translational parallel robots to enhance the normal-direction stiffness using passive limbs. Intel Serv Robotics 10, 333–346 (2017). https://doi.org/10.1007/s11370-017-0229-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11370-017-0229-6