Abstract

Purpose

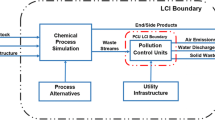

The purpose is to describe and demonstrate the applicability of a bottom-up methodology to build the lifecycle inventory of industrial equipment ubiquitous in chemical processes. The analysis describes concepts of the methodology and demonstrates its functionality in the context of carbon footprint assessment of methanol production.

Methods

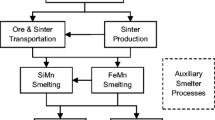

The methodology proposed assumed unit operations are composed of macroscopic components, six structural including steel, concrete, insulation (glass wool), aluminum, powering, and electronic, and one functional, catalyst. Unit operations included heat exchangers (shell-and-tube and air-cooled systems), separation units (flash tanks and distillation column), and a methanol reactor. Sets of equations were provided to estimate the lifecycle inventory (LCI), while relying on scaling parameters as reported in techno-economic assessment techniques (i.e., surface area to estimate heat exchangers costs). A Power-to-X case study (system boundary) was selected to demonstrate the methodology functionality to build the equipment LCI to estimate the CO2 equivalent emissions to produce 1.0 kg of methanol at 25 °C and 1 atm (functional unit).

Results and discussion

The case study showed emissions associated to capital goods amounted to 4146 tonnes of CO2 equivalent, with the methanol reactor having the largest share (67.9%), followed by heat exchangers (23.5%) and separation units (8.6%). Regarding components, steel and concrete comprised the largest contribution for most unit operations (> 53.8% of emissions) excluding the methanol reactor (9.9%). The share of powering and electronics was relevant in the carbon footprint (CF) exercise due to the components intrinsic CF (5.74 and 36.25 kg-CO2 eq./kg-component, respectively) when compared to other major components (i.e., steel, 0.58 kg-CO2 eq./kg-component). The component catalyst had a significant impact on the reactor emissions (80.7%) which originated from the need of being renewed every 2.5-year period. For the system boundary, capital goods only amounted to 0.221% of methanol production emissions or 0.0005 kg-CO2 eq./kg-MeOH.

Conclusion

This study described a novel methodology to estimate the LCI and subsequent CF of capital goods. This new methodology has been used in a specific case study for methanol production using PtX. Ultimately, the authors of this study seek to create the basis of a simple but comprehensive methodology to reduce data gaps associated to lifecycle inventory and assessment of industrial equipment in literature.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- BoP:

-

Balance of plant (i.e., heat exchangers, distillation columns, flash tanks)

- CoP:

-

Core of plant (i.e., electrolyzers and reactors)

- CPT95:

-

Climate protection target with 95% of electricity generated from renewable energy

- FU:

-

Functional unit

- gfi :

-

Gravimetric factor of component i

- gf-stc:

-

Steel-to-concrete gravimetric

- GHG:

-

Greenhouse gases

- GWP100:

-

Global warming potential over a period of 100 years

- HT:

-

High temperature

- kg-MeOH/[h kg-Cat]:

-

STY units in kg of Methanol produced per hour per kg of catalyst

- kg-CO2 eq./kg-component:

-

Weight ratio of kg of CO2 equivalent emitted per kg of component produced

- kg-CO2 eq./kg-MeOH:

-

Weight ratio of kg of CO2 equivalent emitted per kg of methanol produced

- LCA:

-

Lifecycle assessment

- LCI:

-

Lifecycle inventory

- LHV:

-

Low heating value

- MeOH:

-

Methanol

- PEM:

-

Proton exchange membrane

- PtX:

-

Power-to-X, where X stands for fuels or commodities

- SOEC:

-

Solid oxide electrolysis cells

- STY:

-

Space time yield

- Tonne/tonne:

-

Metric ton or 1000 kg

- UUID:

-

Universally unique identifier

References

Adolfsson M, Rashid S (2016) Life cycle assessment and life cycle cost of heat exchangers. A case for inter terminals Sweden AB located in port of Gothenburg. Dissertation, Chalmers University of Technology

Alamri BR, Alamri AR (2009) Technical review of energy storage technologies when integrated with intermittent renewable energy. In: 2009 International Conference on Sustainable Power Generation and Supply. IEEE, Nanjing, China, pp 1–5

Arasto A et al (2013) Post-combustion capture of CO2 at an integrated steel mill - Part I: Technical concept analysis. Int J Green House Gas Control 16:271–277. https://doi.org/10.1016/j.ijggc.2012.08.018

Bareiß K et al (2019) Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Appl Energy 237:862–872. https://doi.org/10.1016/j.apenergy.2019.01.001

Bergins C et al (2015) Power to methanol solutions for flexible and sustainable operations in power and process industries. Power-Gen Europe 1–18

Biswas S et al (2020) A review on synthesis of methane as a pathway for renewable energy storage with a focus on solid oxide electrolytic cell-based processes. Front Energy Res 8. https://doi.org/10.3389/fenrg.2020.570112

Brondani M et al (2020) Life cycle assessment of distillation columns manufacturing. Environ Dev Sustain 22:5925–5945. https://doi.org/10.1007/s10668-019-00459-5

Brynolf S et al (2018) Electrofuels for the transport sector: a review of production costs. Renew Sustain Energy Rev 81:1887–1905. https://doi.org/10.1016/j.rser.2017.05.288

Chen Y et al (2020) Ethylene selectivity in electrocatalytic CO2 reduction on Cu nanomaterials: a crystal phase-dependent study. J Am Chem Soc 142:12760–12766. https://doi.org/10.1021/jacs.0c04981

Chen Z et al (2019) Life cycle assessment of typical methanol production routes: the environmental impacts analysis and power optimization. J Clean Prod 220:408–416. https://doi.org/10.1016/j.jclepro.2019.02.101

de Vasconcelos BR, Lavoie JM (2019) Recent advances in power-to-X technology for the production of fuels and chemicals. Front Chem 7(392):1–24. https://doi.org/10.3389/fchem.2019.00392

Duroudier JP (2016) Distillation, 1st edn. (eBook). Elsevier, San Diego

Ghaib K, Ben-Fares FZ (2018) Power-to-methane: a state-of-the-art review. Renew Sustain Energy Rev 81:433–446. https://doi.org/10.1016/j.rser.2017.08.004

Giraldi MR et al (2015) Life cycle assessment of hydrogen production from a high temperature electrolysis process coupled to a high temperature gas nuclear reactor. Int J Hydrogen Energy 40:4019–4033. https://doi.org/10.1016/j.ijhydene.2015.01.093

Häfele S et al (2016) Life cycle assessment of the manufacture and operation of solid oxide electrolyser components and stacks. Int J Hydrogen Energy 41:13786–13796. https://doi.org/10.1016/j.ijhydene.2016.05.069

Hall PJ et al (2015) Chapter 3: CO2-derived fuels for energy storage. In: Carbon Dioxide Utilisation (eBook), Elsevier, pp 33–44

Hamelinck C, Bunse M (2022) Carbon footprint of methanol. Methanol Institute. https://www.studiogearup.com/wp-content/uploads/2022/02/2022_sGU-for-MI_Methanol-carbon-footprint-DEF-1.pdf (Accessed 22 Oct 2022)

Hoppe W et al (2018) Life cycle assessment of carbon dioxide–based production of methane and methanol and derived polymers. J Ind Ecol 22:327–340. https://doi.org/10.1111/jiec.12583

IEA (2020) Global Energy Review 2019: the latest trends in energy and emissions in 2019. OECD Publishing, Paris,. https://doi.org/10.1787/90c8c125-en. (Accessed 22 Oct 2022)

IEAGHG (2013) Iron and steel CCS study (techno-economics integrated steel mill). http://documents.ieaghg.org/index.php/s/P3rYI5vSh80SPM7 (Accessed 1 Apr 2022)

IRENA (2019) Hydrogen: a renewable energy perspective, International Renewable Energy Agency. https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Hydrogen_2019.pdf?rev=99c1fc338b5149eb846c0d84d633bccd (Accessed 3 Sep 2022)

Kakaç S et al (2020) Heat exchangers: selection, rating, and thermal design, 4th edn. CRC Press, Boca Raton

Khojasteh-Salkuyeh Y et al (2021) CO2 utilization for methanol production; Part I: process design and life cycle GHG assessment of different pathways. J CO2 Util 50:101608 (1–13). https://doi.org/10.1016/j.jcou.2021.101608

Ma W et al (2020) Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C-C coupling over fluorine-modified copper. Nat Catal 3:478–487. https://doi.org/10.1038/s41929-020-0450-0

McCabe W et al (2005) Unit operation of chemical engineering, 7th edn. McGraw Hill, New York

Michailos S et al (2019) Dimethyl ether synthesis via captured CO2 hydrogenation within the power to liquids concept: a techno-economic assessment. Energy Convers Manag 184:262–276. https://doi.org/10.1016/j.enconman.2019.01.046

Mignard D et al (2003) Methanol synthesis from flue-gas CO2 and renewable electricity: a feasibility study. Int J Hydrogen Energy 28:455–464. https://doi.org/10.1016/S0360-3199(02)00082-4

Ontario Ministry of the Environment Conservation and Parks (2021) GHG emissions performance standards and methodology. Government of Ontario. https://www.ontariocanada.com/registry/showAttachment.do?postingId=37527&attachmentId=51425 (Accessed 15 May 2022)

Palma V et al (2018) Chapter 2: state of the art of conventional reactors for methanol production. Methanol (eBook). Elsevier, pp 29–51. https://doi.org/10.1016/B978-0-444-63903-5.00002-9

Pérez-Fortes M et al (2014) CO2 capture and utilization in cement and iron and steel industries. Energy Procedia. Elsevier, pp 6534–6543. https://doi.org/10.1016/j.egypro.2014.11.689

Pérez-Fortes M et al (2016) Methanol synthesis using captured CO2 as raw material: techno-economic and environmental assessment. Appl Energy 161:718–732. https://doi.org/10.1016/j.apenergy.2015.07.067

Peters MS et al (2002) Plant design and economics for chemical engineers, 5th edn. McGraw-Hill Professional, New York

Phillips SD et al (2011) Gasoline from wood via integrated gasification, synthesis, and methanol-to-gasoline technologies. Technical report NREL/TP-5100–47594, United States. https://doi.org/10.2172/1004790

Qin Z et al (2016) Carbon footprint evaluation of coal-to-methanol chain with the hierarchical attribution management and life cycle assessment. Energy Convers Manag 124:168–179. https://doi.org/10.1016/j.enconman.2016.07.005

Schreiber A et al (2020) Life cycle assessment of power-to-syngas: comparing high temperature co-electrolysis and steam methane reforming. Front Energy Res 8:1–17. https://doi.org/10.3389/fenrg.2020.533850

Sjoberg-Elf J, Wannheden-Espinosa K (2017) Carbon capture and utilisation in the steel industry a study exploring the integration of carbon capture technology and high-temperature co-electrolysis of CO2 and H2O to produce synthetic gas. Dissertation. KTH Royal Institute of Technology

Sternberg A et al (2017) Life cycle assessment of CO2-based C1-chemicals. Green Chem 19:2244–2259. https://doi.org/10.1039/c6gc02852g

Suebsiri J, Wilson M (2011) A model of carbon capture and storage with demonstration of global warming potential and fossil fuel resource use efficiency. Energy Procedia 4:2465–2469. https://doi.org/10.1016/j.egypro.2011.02.141

Tsupari E et al (2013) Post-combustion capture of CO2 at an integrated steel mill - Part II: Economic feasibility. Int J Green House Gas Control 16:278–286. https://doi.org/10.1016/j.ijggc.2012.08.017

Wang S et al (2009) Dimethyl ether synthesis via CO2 hydrogenation over CuO-TiO2-ZrO2/HZSM-5 bifunctional catalysts. Catal Commun 10:1367–1370. https://doi.org/10.1016/j.catcom.2009.02.001

Zang G et al (2021) Technoeconomic and life cycle analysis of synthetic methanol production from hydrogen and industrial by-product CO2. Environ Sci Technol 55:5248–5257. https://doi.org/10.1021/acs.est.0c08237

Zimmermann A et al (2018) Techno-economic assessment & life cycle assessment guidelines for CO2 utilization. Front Energy Res 8(5):1–23. https://doi.org/10.3389/fenrg.2020.00005

Acknowledgements

The authors gratefully acknowledge financial support from National Science and Engineering Research Council Canada (NSERC) and the Materials for Clean Fuels (MCF) Challenge program issued by the National Research Council Canada (NRC). We appreciate the productive discussions with our colleagues Samira Lotfi, Jalil Shadbahr, Giovanna Gonzales-Calienes, and Miyuru Kannangara.

Funding

The authors acknowledge the financial support from the Materials for Clean Fuels (MCF) Challenge Program issued by the National Research Council Canada (NRC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Chris Yuan.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A novel methodology to estimate the embedded carbon of capital goods in Power-to-X systems (PtX) is proposed.

• The bottom-top methodology follows calculation procedures similar to those applied in techno-economic assessment, relying on scaling variables (i.e., area in m2 for heat exchangers).

• Unit operations are assumed to require up to seven macroscopic components to be operational on-site, including steel, concrete, powering and electronics materials, glass wool, aluminum and catalyst.

• A PtX case study is taken from literature and the methodology is applied to assess the impact of unit operation on the normalized carbon footprint of methanol production.

• The case study showcases the relative low impact of capital goods (components) on the normalized carbon footprint of methanol (0.045–0.161%), largely due to the dominance of emissions associated to plant operation.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Castellanos-Beltran, I.J., de Medeiros, F.G.M., Bensebaa, F. et al. Novel bottom-up methodology to build the lifecycle inventory of unit operations: the impact of macroscopic components. Int J Life Cycle Assess 28, 669–683 (2023). https://doi.org/10.1007/s11367-023-02165-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02165-x