Abstract

Purpose

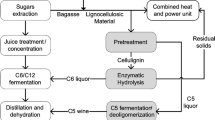

Bioethanol demands for transport face uncertainty; additionally, the emergence of electric vehicles is raising concerns among the ethanol producers towards the future demand and viability of the industry. Thus, there is a need to look for new pathways of sugar and ethanol utilization. However, the environmental and economic implications of the existing and proposed systems must be assessed to ensure sustainability. The study aims to evaluate and compare the environmental and economic performances of sugarcane for three new sugar-electricity-polylactic acid (PLA) systems with the existing sugar-electricity-ethanol system. The environmental hotspots of the existing and proposed sugarcane biorefinery systems are investigated and potential measures for enhancing environmental sustainability of the new systems identified.

Methods

Life cycle assessment (LCA) is used for evaluating the environmental sustainability assessment of the sugarcane biorefinery and the eco-efficiency indicator, combining both the economic and environmental performances. The ReCiPe method with the hierarchist perspective at midpoint and the endpoint levels is used for quantifying the environmental impact scores. The reference unit is a tonne of cane processed at the biorefinery. The eco-efficiency is calculated based on the ReCiPe endpoint single score (“Pt”) and the values in “US$” of products from the different biorefinery systems.

Results and discussion

The results reveal that the PLA pathways to substitute ethanol and sugar production (PLA scenarios 1–3) can generate product values of about 83–220 US$/t cane processed leading to increased eco-efficiency values for all three PLA scenarios as compared to the existing sugar-electricity-ethanol system. The highest eco-efficiency (22 US$/Pt) is obtained for the pathways of PLA (scenario 3) and sugar-PLA (scenario 2). However, the LCA results show increased environmental impacts for all three PLA biorefinery scenarios. This implies that the new PLA pathways do not lead to “strong” eco-efficiency improvement, i.e., the improvement is not in both environmental and economic dimensions. Recommendations are provided to improve the environmental performances of both the existing and the new PLA biorefinery systems.

Conclusions

The sugarcane-based PLA biorefinery could be an option for the case that the existing sugar-electricity-ethanol faces an uncertainty on ethanol demand. Nevertheless, there is a trade-off between the increased environmental impacts and the higher price. Strong eco-efficiency improvement must be encouraged to the sugarcane-based PLA biorefinery systems. Using high-pressure boilers at the mills and changing cultivation practices to avoid the cane trash burning are recommended for the better decoupling of the environmental and economic performance of the sugarcane biorefinery systems.

Similar content being viewed by others

References

Alibaba (2017) PLA price. https://www.alibaba.com/showroom/pla.html. Accessed 10 Dec 2017

Alvarenga RAF, Dewulf J (2013) Plastic vs. fuel: which use of the Brazilian ethanol can bring more environmental gains? Renew Energy 59:49–52

BOT (2017) Ethanol situation report year 2016. Bank of Thailand, Bangkok [in Thai]. https://www.bot.or.th/Thai/MonetaryPolicy/NorthEastern/Pages/commodities.aspx. Accessed 20 July 2018

Braunbeck OA, Magalhães PSG (2014) Technological evaluation of sugarcane mechanization. Sugarcane Bioethanol-R&D for Productivity and Sustainability. Editor Edgard Blücher, São Paulo, pp 451–464

Changwichan K, Silalertruksa T, Gheewala SH (2018) Eco-efficiency assessment of bioplastics production systems and end-of-life options. Sustainability 10:952

Christofoletti CA, Escher JP, Correia JE, Marinho JFU, Fontanetti CS (2013) Sugarcane vinasse: environmental implications of its use. Waste Manag 33:2752–2761

DEDE (2017) Ethanol production statistics. Department of Alternative Energy Development and Efficiency. http://www.dede.go.th/more_news.php?cid=81&filename=index. Accessed 1 May 2017

Dias MOS, Junqueira TL, Cavalett O, Cunha MP, Pavanello LG, Cunha MP, Jesus CDF, Filho RM, Bonomi A (2013) Biorefineries for the production of first and second generation ethanol and electricity from sugarcane. Appl Energy 109:72–78

Ecoinvent (2012) Swiss Centre for Life Cycle Inventories. Ecoinvent Data v3.0. Swiss Centre for Life Cycle Inventories

European-Bioplastics (2018) Bioplastics market data. Available online: http://www.european-bioplastics.org/market/. Accessed 20 Dec 2018

FAOSTAT (2018) Food and Agriculture Organization of the United Nations: Statistics Division. http://www.fao.org/faostat/en/#data/QC. Accessed 22 Sept 2018

Fito J, Tefera N, Van Hulle SWH (2019) Sugarcane biorefineries wastewater: bioremediation technologies for environmental sustainability. Chem Biol Technol Agric 6:9

Groot WJ, Borén T (2010) Life cycle assessment of the manufacture of lactide and PLA biopolymers from sugarcane in Thailand. Int J Life Cycle Assess 15:970–984

Huijbregts MAJ, Steinmann ZJN, Elshout PMF, Stam G, Verones F, Vieira MDM, Hollander A, Zijp M, Zelm RV (2016) ReCiPe 2016: a harmonized life cycle impact assessment method at midpoint and endpoint level. Report I: characterization. RIVM Report 2016-0104

Huppes G, Ishikawa M (2009) Eco-efficiency guiding micro-level actions towards sustainability: ten basic steps for analysis. Ecol Econ 68:1687–1700

ISO 14045 (2012) Environmental management—eco-efficiency assessment of product systems—principles, requirements and guideline. Geneva

Jenjariyakosoln S, Gheewala SH, Sajjakulnukit B, Garivait S (2014) Energy and GHG emission reduction potential of power generation from sugarcane residues in Thailand. Energy Sustain Dev 23:32–45

Khatiwada D, Seabra J, Silveira S, Walter A (2012) Power generation from sugarcane biomass—a complementary option to hydroelectricity in Nepal and Brazil. Energy 48:241–254

Long X, Zhao X, Cheng F (2015) The comparison analysis of total factor productivity and eco-efficiency in China’s cement manufactures. Energy Policy 81:61–66

Madival S, Auras R, Singh SP, Narayan R (2009) Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J Clean Prod 17:1183–1194

Moncada J, Matallana LG, Cardona CA (2013) Selection of process pathways for biorefinery design using optimization tools: a Colombian case for conversion of sugarcane bagasse to ethanol, poly-3-hydroxybutyrate (PHB), and energy. Ind Eng Chem Res 52(11):4132–4145

MTEC (2014) Thailand national LCI database. National Metal and Materials Technology Center, Bangkok

Nishihara Hun AL, Mele FD, Pérez GA (2017) A comparative life cycle assessment of the sugarcane value chain in the province of Tucumán (Argentina) considering different technology levels. Int J Life Cycle Assess 22:502–515

Nonato RV, Mantelatto PE, Rossell CEV (2001) Integrated production of biodegradable plastic, sugar and ethanol. Appl Microbiol Biotechnol 57(1–2):1–5

OCSB (2014) Production report on sugar and sugarcane (Season 2013/2014). Office of the Cane and Sugar Board, Bangkok

OCSB (2017) Production report on sugar and sugarcane (season 2016/2017). Office of the Cane and Sugar Board, Bangkok

Pereira LG, Chagas MF, Dias MOS, Cavalett O, Bonomi A (2015) Life cycle assessment of butanol production in sugarcane biorefineries in Brazil. J Clean Prod 96:557–568

Plastics Insight (2019) Polylactic acid properties, production, price, market and uses. https://www.plasticsinsight.com/resin-intelligence/resin-prices/polylactic-acid/#price. Accessed 10 Feb 2019

Pongpat P, Gheewala SH, Silalertruksa T (2017) An assessment of harvesting practices of sugarcane in the central region of Thailand. J Clean Prod 142:1138–1147

Ragauskas AJ, Williams CK, Davisons BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ, Hallett JP, Leak DJ, Liotta CL, Mielenz JR, Murphy R, Templer R, Tschaplinski T (2006) The path forward for biofuels and biomaterials. Science 311:484–489

Renó MLG, Olmo OA, Palacio JCE, Lora EES, Venturini OJ (2014) Sugarcane biorefineries: case studies applied to the Brazilian sugar-alcohol industry. Energy Convers Manag 86:981–991

Renouf MA, Pagan RJ, Wegener MK (2011) Life cycle assessment of Australian sugarcane products with a focus on cane processing. Int J Life Cycle Assess 16:125–137

Renouf MA, Pagan RJ, Wegener MK (2013) Bio-production from Australian sugarcane: an environmental investigation of product diversification in an agro-industry. J Clean Prod 39:87–96

Saling P (2016) Eco-efficiency assessment. In: Finkbeiner M (ed) Special types of life cycle assessment. LCA Compendium – The Complete World of Life Cycle Assessment. Springer, Dordrecht

Seabra JEA, Macedo IC, Chum HL, Faroni CE, Sarto CA (2011) Life cycle assessment of Brazilian sugarcane products: GHG emissions and energy use. Biofuel Bioprod Biorefin 5(5):519–532

Silalertruksa T, Gheewala SH, Pongpat P (2015) Sustainability assessment of sugarcane biorefinery and molasses ethanol production in Thailand using eco-efficiency indicator. Appl Energy 160:603–609

Silalertruksa T, Pongpat P, Gheewala SH (2017) Life cycle assessment for enhancing environmental sustainability of sugarcane biorefinery in Thailand. J Clean Prod 140(Part 2):906–913

Smeets E, Junginger M, Faaij A, Walter A, Dolzan P, Turkenburg W (2008) The sustainability of Brazilian ethanol—an assessment of the possibilities for certified production. Biomass Bioenergy 32:781–813

Sriroth K (2017) Thailand’s Bioeconomy & Biorefinery Development and Roles of Mitr Phol R&D. Presentation of the conference on “Biomass to Energy, Chemicals and Functional Materials”. Japan-ASEAN Science, Technology and Innovation Platform (JASTIP), Bangkok

Statista (2018) Average annual OPEC crude oil price from 1960 to 2018. https://www.statista.com/statistics/262858/change-in-opec-crude-oil-prices-since-1960/. Accessed 20 Sept 2018

Suwanmanee U, Varabuntoonvit V, Chaiwutthinan P, Tajan M, Mungcharoen T, Leejarkpai T (2013) Life cycle assessment of single use thermoform boxes made from polystyrene (PS), polylactic acid, (PLA), and PLA/starch: cradle to consumer gate. Int J Life Cycle Assess 18:401–417

Tsiropoulos I, Faaij APC, Lundquist L, Schenker U, Briois JF, Patel MK (2015) Life cycle impact assessment of bio-based plastics from sugarcane ethanol. J Clean Prod 90:114–127

van den Wall Bake JD, Junginger M, Faaij A, Poot T, Walter A (2009) Explaining the experience curve: cost reductions of Brazilan ethanol from sugarcane. Biomass Bioenergy 33:644–658

Verfaillie HA, Bidwell R (2000) Measuring eco-efficiency: a guide to reporting company performance. World Business Council for Sustainable Development, Geneva

Acknowledgments

The authors acknowledge the financial support from the King Mongkut’s University of Technology Thonburi through the “KMUTT 55th Anniversary Commemorative Fund” and the National Science and Technology Development Agency (NSTDA) through the Research Chair Grant 2559 (RD&E Fund: FDA-CO-2559-3268-TH).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Hayo M.G. van der Werf

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silalertruksa, T., Gheewala, S.H. Competitive use of sugarcane for food, fuel, and biochemical through the environmental and economic factors. Int J Life Cycle Assess 25, 1343–1355 (2020). https://doi.org/10.1007/s11367-019-01664-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-019-01664-0