Abstract

Purpose

Animal by-products may be increasingly relied upon to satisfy nutritional requirements of salmonids and other fed aquaculture species as demand for fish meal outpaces supply. Previous studies of aquaculture supply chains have included either no animal by-product inputs or small inputs of poultry by-products. Australian Atlantic salmon production includes high use of feed inputs derived from poultry and mammalian by-products and provides a case study to explore the environmental implications and methodological challenges associated with these inputs.

Methods

Life cycle assessment was carried out on a vertically integrated salmon production system in Tasmania, representing approximately 40% of Australian Atlantic salmon production. The system included feed production, smolt/juvenile production, farm grow-out, processing and packaging, and distribution of head-on gutted salmon to market. Impacts from animal production were allocated to by-products on a gross chemical energy basis. Scenario analyses were conducted to determine the extent to which changes in feed conversion ratio, feed composition, and other variables affect results. Sensitivity analysis was carried out on the allocation method for fishery and animal by-products.

Results and discussion

Environmental impacts associated with Tasmanian salmon fed high quantities of animal by-products were markedly higher than those of previously assessed systems. All impacts were driven by feed production with the exception of eutrophication potential, which was driven equally by feed production and nutrient loss during grow-out. Animal by-products accounted for the majority of all impacts from feed production. Adopting a feed composition without animal by-products would result in dramatic improvements, including a 70% decrease in greenhouse gas emissions. Allocation choice had a clear effect on results, with biophysical allocation methods placing much more burden from animal production on fed systems than economic or no-impact allocation methods.

Conclusions

The use of animal by-product inputs in aquaculture feeds has a substantial effect on the environmental profile of farmed salmon products. The magnitude of this effect is dependent on the allocation method chosen for the treatment of products and by-products in upstream systems. The high impact of such systems recognizes the environmental cost of future aquaculture production that may rely more on intensive and high-impact animal production inputs as more efficient fishery inputs become increasingly limited relative to demand.

Similar content being viewed by others

1 Introduction

Production of feed is a potential constraining factor in the growth of many aquaculture systems and is a significant source of environmental impact in aquaculture supply chains. Approximately half of global aquaculture production relies on the input of compound feeds (FAO 2016b). Global per capita fish consumption has increased steadily, driven largely by income growth and urbanization in developing countries (FAO 2016c), and aquaculture production will need to increase by a further 40% to satisfy the projected 186 million tonnes demand for fish by 2030 (World Bank 2012). Fed aquaculture production is currently expanding faster than non-fed production (FAO 2016b), and much of the predicted growth can be expected to come from fed species, particularly if increasing affluence in developing countries results in adoption of more western diets.

Historically, wild capture fisheries have satisfied many of the nutritional requirements of fed aquaculture species. A total of 15.8 million tonnes of wild fishery landings were destined to the production of meal and oil in 2014 (FAO 2016b). The proportion of these products directed to aquaculture has increased steadily: by 2010, 73% of fish meal was used as input to aquafeeds, up from 10% in 1980 and 28% in 1995 (Tacon and Metian 2008; Shepherd and Jackson 2013). Likewise, 80% of fish oil was destined for aquafeed input in 2010, up from 16% in 1980 and 34% in 1995 (Tacon and Metian 2008; Shepherd and Jackson 2013). Carnivorous species such as salmonids and shrimps are amongst the top consumers. Despite noticeable improvement in economic feed conversion ratios (FCRs, kg of dry feed input per kg of whole fish slaughtered) and decreasing rates of fish meal and oil in feeds over the past two decades, growth in aquaculture production has been rapid enough that demand for fish meal and oil has outpaced supply (Tacon and Metian 2008; Naylor et al. 2009; Shepherd and Jackson 2013). This has resulted in rising fish meal and oil prices, providing an economic impetus to seek alternatives. This is not a new challenge, as the aquaculture industry has been investigating opportunities to diversify feed compositions and reduce fishery input rates since the 1990s and before (Steffens 1994; Hardy 1996; El-sayed 1999).

Animal by-product feed inputs are here defined as co-products from animal production systems, excluding fish, destined for use in feeds rather than human consumption. Animal by-products that have been used to replace fish meal and fish oil include poultry meal and oil, feather meal, mammalian (e.g., bovine) meal, and blood meal (Steffens 1994; Millamena 2002; Samocha et al. 2004). Nutritionally, animal by-products have generally been favored over plant-based options as alternatives to fish inputs due to their protein content, amino acid profiles, and relative palatability and digestibility (Carter and Hauler 2000; Samocha et al. 2004). Globally, however, animal by-products still account for a relatively small portion of commercial salmon feeds. Pelletier et al. (2009), collecting data representing 70% of global salmon feed production, reported animal by-product inclusion rates of 20% in Canada, 15% in Chile, and 0% in both Norway and the United Kingdom.

Feed production typically accounts for the vast majority of environmental burden in life cycle assessments (LCAs) of salmonid systems up to the farm-gate (Pelletier et al. 2009; Aubin et al. 2009; d’Orbcastel et al. 2009; Boissy et al. 2011). This is particularly the case for salmon grown in marine net pens, as energy inputs are relatively low; electricity inputs to recirculating systems drawing upon fossil fuel-intensive generation grids have been shown to dominate LCA results in some cases (Ayer and Tyedmers 2009; Samuel-Fitwi et al. 2013b). Importantly, most LCAs of salmonid aquaculture have included little or no inputs from animal by-products. While two of the regions assessed by Pelletier et al. (2009) did include animal by-products and those products contributed disproportionately to overall impact, they still accounted for less than 20% of their respective feed compositions and did not include any mammalian by-products. To date, salmonid systems which rely heavily on animal by-product inputs as a protein source in replacement of fish inputs have received less attention.

The Australian Atlantic salmon (Salmo salar) industry began with the import of eggs from Canada to New South Wales in the 1960s for wild river stocking. Eggs from this sport fishing population were subsequently used for exploratory farming in the island state of Tasmania in the 1980s. Today, the industry is located almost exclusively in Tasmania. In 2014–15, production of Tasmanian salmonids reached 47,200 t, with a gross value of AUD $620 million (~US $465 million) (Savage 2015). Production has expanded rapidly over the past decade, growing by 330% between 2005 and 2015. Most harvested salmon is transported to mainland Australia and sold domestically, although products are also increasingly destined for international markets.

The production of Tasmanian Atlantic salmon is unique within the global industry not just in its environment and genetics, but in the amount and type of feed used. Observed FCRs have been higher than those reported in other regions, ranging from 1.4 to 1.6 in 2006, compared to a global average of 1.3 (Tacon and Metian 2008). Further, feed mixes used by the Tasmanian industry in recent years have included substantially higher inputs of animal by-products than seen in other regions. White (2013) assessed Tasmanian salmon feeds and salmon production and observed an animal by-product inclusion rate of 38%, in addition to 8% from fish by-products. Animal by-products present in Tasmanian salmon feed compositions include poultry meal, poultry oil, feather meal, mammalian (bovine- and porcine-derived) meal, and blood meal.

This paper has four objectives. First, to quantify the life cycle environmental impacts of Tasmanian-produced Atlantic salmon, including all stages up to the point of arrival at market, and to identify drivers of impact along the supply chain. Second, to model relative environmental performance achieved by diverse scenarios relating to both feed inputs and other aspects of the salmon supply chain. Third, to assess the sensitivity of LCA results for such a system to the selected method of allocating impacts from animal production to by-products. Fourth, to compare results to previous studies and discuss the methodological challenges and environmental implications associated with fed aquaculture systems which rely heavily on animal by-product inputs.

2 Methods

LCA was carried out on the operations and products of one vertically integrated Tasmanian salmon producer that operates three farming sites as well as a number of smolt production sites and a processing facility. The producer’s farms supplied roughly 40% of Australian Atlantic salmon production in 2015.

Environmental impacts were assessed for a functional unit of 1 kg of head-on gutted (HOG) salmon, processed, packaged, and distributed to domestic Australian markets. For the purpose of comparison, and because many aquaculture LCAs do not extend past the farm-gate, impacts were also quantified per tonne of whole salmon at farm-gate. The time frame of the study included calendar years 2013 to 2015, with some amendments to the time frame necessary to correct for uneven production between years.

2.1 Inventory analysis

The system boundaries encompassed feed provision, smolt production, farm grow-out, processing and packaging, and distribution to markets (Fig. 1). This followed the product to the point of departure from the producer’s influence, thus excluding sale and consumption. Inputs to feed production included: production and processing of crop, fishery, and animal by-product inputs; transportation of inputs to feed mills; energy inputs to milling; packaging; and transport of feed from manufacturers to smolt sites and farms. Inputs to smolt production included: feeds; fuels and electricity; chemicals and liquid oxygen; and smolt transport. Inputs to farm grow-out included: feeds; fuels and electricity; chemicals; nets and ropes; and net resin. Inputs to processing and packaging included: transport of slaughtered salmon to the processing facility; fuels and electricity; chemicals; salt; and polyethylene-lined polystyrene boxes for packaging. Inputs to distribution included transport via ferry (between Tasmania and Melbourne) and truck to destinations throughout Australia.

Foreground data for smolt production, farm grow-out, processing, and distribution were sourced directly from the producer. Feed composition, feed milling, and feed input source data were solicited from three feed manufacturers that together supplied all feeds used during the study period. Several smolt sites not operated by the producer also provided smolts during the study period, and data were solicited directly from these contract smolt providers. Distribution distances were calculated based on the quantity of product shipped to each state during the study period. Operational and fuel consumption data for ferry transport between Tasmania and Melbourne were supplied by the Spirit of Tasmania ferry.

Background data were sourced from the ecoinvent 3.0 (Weidema et al. 2013) and Agri-footprint 2.0 (Durlinger et al. 2014) life cycle inventory databases. All database records were amended to use relevant electricity generation mixes, transport modes, and transport distances. Annual Tasmanian electricity generation mixes were formulated based on annual generation by hydropower, natural gas, and wind, as well as imports from and exports to mainland Australia. Agri-footprint unit processes for poultry, beef, and pork production and processing were amended to reflect Australian electricity grids and transport, processing yields, and poultry feed composition and energy use (Weidemann et al. 2012). Operational inputs to fisheries were calculated from a database of species-, gear-, and country-specific rates of fuel use per tonne of round weight landings (Parker and Tyedmers 2015). Species-specific fish meal and oil yields were taken from Parker and Tyedmers (2012) and Cashion et al. (2017). Inputs to fish reduction processing included electricity, natural gas, and diesel at rates reported by Parker (2011). Transportation distances for feed inputs were estimated based on distance from country-specific production regions to major rail stations and sea ports, and sea transport distance to feed mills (S & P Global, 2017). Transport modes and routes of processed feeds were provided directly by suppliers.

Allocation of impact between co-products was required at several stages throughout the supply chain. Co-products arising from crop, fishery, and animal by-product feed inputs were allocated based on energy density, reflecting the function of those products as energy providers and following the method of previous salmon LCAs (Pelletier et al. 2009). In the case of fish mortalities and sludge from smolt production and farms used for production of compost, allocation was avoided by use of system expansion: the quantity of chemical nitrogen and phosphorus content of products was calculated to determine an offset quantity of synthetic nitrogen and phosphorus fertilizer, taking into account the use of formic acid for ensilage. Mortalities which were not destined for use as a co-product were excluded from analysis. Allocation between co-products from land-based animal production at the slaughterhouse was conducted using Australian production values reported by Weidemann and Yan (2014) (Table 1). Data were not available to sub-divide processing between HOG production and other products, and so energy inputs to processing were allocated on a mass basis between HOG and other salmon products (e.g., smoked, cured). Allocation of operational inputs to the Spirit of Tasmania ferry was allocated to trucks on the basis of vehicle length relative to total vehicle length capacity. Allocation of truck transport was conducted on a mass basis.

2.2 Impact assessment

Impact categories for assessment were selected based on their typical application in seafood LCAs. They included: global warming potential (GWP) in kg CO2-eq emissions using 100-year characterization factors; cumulative energy demand (CED) in MJ; acidification potential (AP) in kg SO2-eq emissions; eutrophication potential (EP) in kg PO4-eq emissions; ozone depletion potential (ODP) in kg CFC-11-eq emissions; and photochemical oxidation potential (POP) in kg C2H4-eq emissions. Importantly, this suite of impact categories limited analysis to energy use and emissions, excluding novel impacts assessed by some previous LCAs, such as biotic resource use (e.g., appropriation of net primary productivity), water use, and land use (Pelletier et al. 2007; Henriksson et al. 2012). Assessment was also limited to mid-point indicators, rather than end-point measures as have been applied by some studies using various techniques such as the weighted ReCiPe method (Goedkeep et al. 2009). All models were run in SimaPro 8.1 LCA software (PRé Consultants bv 2013), and characterization factors were applied using the CML-IA method baseline (Guinée, 2001).

2.3 Scenarios and sensitivity analysis

Scenario analyses were conducted to explore the effect of alternative models: following the product to an export market (Japan) using air transport; replacing feed compositions with those reported from other regions by Pelletier et al. (2009), maintaining feed source materials but amending overall ratio of crops, fishery inputs, and animal by-products; replacing the FCR with the average value of 1.3 reported by Tacon and Metian (2008); assuming optimal energy use values for all smolt producers and farms (i.e., applying the values from the most efficient smolts/farms to all locations); and assuming a hypothetical optimal scenario which includes the lowest-impact feed composition, FCR, and energy use from other scenarios. Feed composition scenarios did not consider any differences in the macro- or micro-nutrient content, digestibility, palatability, or growth rates achievable by different feed compositions. Uncertainty analysis was not undertaken, although selection of data, characterization models, and observed variation in primary data all contribute to uncertainty to varying degrees for each impact category (Geisler et al. 2005). Uncertainty in aquaculture LCAs, while not commonly quantified, has been explored in some novel applications and may be used to better contextualize future assessments (Henriksson et al. 2014).

Sensitivity of results to the choice of allocation for animal by-product inputs was explored in closer detail due to the substantial difference in economic value of co-products and the potential consideration of animal by-products as a “waste” or insignificant side-effect of animal protein production. The allocation values used for this analysis were based on data from Australian slaughter houses reported by Weidemann and Yan (2014) (Table 1). Beef, pork, and poultry were all assumed to contribute to the production of blood meal, while beef and pork were assumed to contribute to the production of mammalian meal. Energy and economic allocation values were mass-adjusted for analysis to maintain consistent slaughter yields.

3 Results

3.1 Inventory analysis results

A total of 62,500 t of whole salmon at farm-gate were produced during the three-year study period, and 43,800 t of HOG salmon, along with 10,900 t of other salmon products (e.g., smoked), were processed.

Feed inputs during the study period totaled 103,000 t. The economic FCR across all production was 1.65, including 1.61 at farm grow-out and 0.04 for smolt production. The lowest annual FCR achieved at a single farm was 1.33. Feeds were purchased from three manufacturers in Australia and the United Kingdom, and inputs were sourced from at least 13 countries worldwide. Feed composition was 28% crop inputs, 24% fishery inputs, 37% animal by-product inputs, and 7% undisclosed or technical inputs (Table 2). Average transport distance of feed ingredients from source to feed mills was 8800 km, of which 79% was by sea. Additional milling inputs per tonne of feed included 132 kWh of electricity, 9.6 m3 of natural gas, and 3.1 kg of plastic packaging materials. Average transport of feed from mills to smolt producers and farms was 3060 km, including 690 km by transoceanic ship, 1970 km by land (rail and road), and 400 km by ferry.

Energy inputs to smolt production, farm grow-out, and processing were in the form of electricity, diesel, petrol (gasoline), and liquid natural gas (Tables 3 and 4). Electricity was primarily produced by hydroelectric dams in Tasmania, although a link with mainland Australia allows for electricity imports and exports. Mainland electricity is primarily coal-generated. Tasmanian generation over the study period was 84% hydroelectric, 8% wind, and 8% natural gas. Net imports from mainland Australia were positive in one of the three years assessed, accounting for 15% of local electricity demand in 2014/15.

Transport of smolts to farms and of slaughtered salmon to processing was undertaken using specially-designed trucks which hold fish in tanks along with, in the case of slaughtered salmon, gel ice produced locally. Diesel inputs to smolt transport were 132 l per tonne of smolts. Transport of salmon to processing required 35 l of diesel and 0.6 m3 of gel ice per tonne of whole salmon.

Distribution of HOG salmon from processing to market included an average of 659 km by truck and 356 km by ferry (Table 5). Forty percent of the product was shipped to New South Wales, 25% to Victoria, and 18% to other destinations in Australia. A further 17% percent was exported, primarily to Japan; international transport was excluded from analysis here, but it was modeled as a scenario.

3.2 Impact assessment results

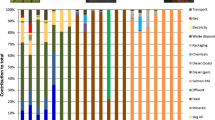

Quantified contributions of Tasmanian Atlantic salmon production to each impact category are presented in Table 6. Feed production was the primary contributing stage to all impact categories (Fig. 2). Production, processing, and transport of feed together accounted for 93% of GWP of HOG salmon at market, and an average of 81% across all impact categories. Smolt production, excluding feed, contributed less than 2% to all impacts categories for HOG salmon. Farm grow-out, excluding feed, contributed markedly (48%) to EP as a result of fish waste and uneaten feed, and noticeably to CED and ODP as a result of diesel combustion by vessels. Distribution contributed 7% to ODP and relatively little to all other impact categories.

Contribution of production stages to the environmental burden of Tasmanian Atlantic salmon. a Shows only feed-related stages, while b shows the entire life cycle up to arrival of processed HOG salmon at market. Impacts from smolt production and grow-out show contribution of all inputs to those stages excluding feed, which is reported separately

Animal by-product inputs dominated impact contributions from feed production, averaging 68% of feed-related burden across all categories and 55% of total burden of HOG salmon at market (Fig. 2). Animal by-products contributed most heavily across the entire supply chain to GWP (70%) and AP (74%). While animal by-products contributed substantially to EP relative to other feed inputs, the relative contribution across the entire supply chain was lower (41%) due to the high eutrophying emissions at grow-out. Crops and fishery inputs contributed on average 7 and 9% of feed-related impacts, while milling, packaging, and transport of feed contributed 10%.

3.3 Scenarios and sensitivity analysis results

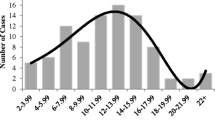

Results of scenario analyses conducted on the supply chains of salmon at farm-gate and HOG salmon at market are displayed in Tables 7 and 8. Of the scenarios considered, the most dramatic effects resulted from changing the feed composition to mirror the general feed mixes reported by Pelletier et al. (2009), in particular the feed mix reported for Norway which contains no animal by-products. GWP of Tasmanian salmon could be reduced by nearly 70% by using feeds composed entirely of crop and fish inputs rather than animal by-product inputs. Improving the FCR of Tasmanian Atlantic salmon could also achieve marked improvements across all impact categories, with a particular effect on EP due to the lower loss of nutrients during grow-out. Scenarios involving the improvement of energy use rates in smolt production and farm grow-out resulted in dramatically smaller improvements to impacts compared to feed-related scenarios. Transporting products internationally to Japan by air freight would see increases in impact between 4% (EP) and 276% (ODP), with additional dramatic increases in both GWP and CED. Overall, the optimal production scenario, including FCR, feed composition, and energy consumption rates, could hypothetically reduce the GWP of Tasmanian HOG salmon at market by 74%, and could reduce other impacts by 39–77%.

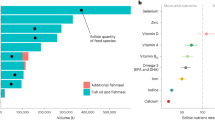

Methodological sensitivity analysis revealed that the method of allocating impacts of animal and fish production and processing to by-products of those systems had a dramatic effect on results. Use of mass allocation—which attributes less impact to high-fat co-products like oils—resulted in higher impacts for most categories, increasing the GWP of salmonid feeds by 38% and the GWP of HOG salmon at market by 36%. Economic allocation, unsurprisingly, resulted in substantial decreases in modeled impact across all categories, including a 68% lower GWP of salmonid feeds and 59% lower GWP of HOG salmon at market. Treatment of by-products as waste products and allocating no impact to them resulted in a 79% decrease in GWP of salmonid feeds and a 69% decrease in GWP of HOG salmon at market (Fig. 3). Given the low economic value of by-products compared to food-grade primary products, the results from the economic and no-impact scenarios were very similar.

Environmental burden of HOG salmon at domestic markets in Australia, modeled using alternative methods to allocate impacts from production and processing of animal by-products and fish by-products. Values are relative to the base case analysis using energy (gross nutritional energy content) allocation

4 Discussion

4.1 Comparison to previous studies

The Tasmanian production system assessed here included both the highest rate of animal by-product inputs and the highest FCR of all published salmonid LCAs to date (Table 9). In addition, it is one of only two studies to include the input of mammalian by-product inputs, the other being White’s (2013) previous assessment of Tasmanian salmon production. Accordingly, Tasmanian salmon at farm-gate had a higher GWP than most previously assessed systems, with two exceptions being land-based recirculating systems with markedly higher energy inputs than marine net pens (Samuel-Fitwi et al. 2013b; Ayer and Tyedmers 2009). The pattern of feed inputs driving impacts reflects that found in other salmonid LCAs, as does the relatively small contribution observed from processing, packaging, and distribution. The finding that air transport could dramatically increase emissions supports that of previous LCAs which assessed transport mode scenarios for high-value seafood products such as lobster (Driscoll et al. 2015; van Putten et al. 2016).

Beyond the values for Tasmanian production, there is an inconsistent relationship between the portion of feed inputs derived from animal by-products and the GWP of salmon output (Table 9). Several factors help to explain this. One previous study including animal by-products (Dekamin et al. 2015) did not specify the allocation method but it can be assumed based on the very low impact per tonne of feed that impacts were either not allocated to by-products at all or were done so based on economic value. While several other studies have examined feeds with animal by-product inputs, those inputs have been solely sourced from poultry, which is associated with a substantially lower GWP than mammalian production. Further, inputs from previous studies have typically been poultry meal rather than oil, and meal is allocated a lower impact using energy allocation due to its lower energy density (e.g., Pelletier et al. 2009). The highest rate of animal feed inputs in a salmonid LCA outside of Tasmania was in a scenario examined by Ytrestoyl and colleagues (2011) which included meals and oil from poultry; while their scenario resulted in a higher GWP than systems excluding animal inputs entirely, the modeled emissions were still much lower than those found here. The relatively high GWP of poultry meal inclusion in Chilean feeds found by Pelletier et al. (2009) was also attenuated to a degree by the low GWP of fish meal from highly efficient anchoveta (Engraulis ringens) fisheries (Fréon et al. 2014).

4.2 Present and future environmental implications

It is unclear the actual extent to which animal by-products, and mammalian by-products in particular, are used as inputs to aquafeeds globally, although there are reasons beyond just their seldom inclusion in LCAs to suspect it is relatively low. Their use in any feed is controlled and in many cases prohibited in the European Union in response to bovine spongiform encephalopathy (BSE) or mad cow disease (Regulation (EC) No. 999/2001 of the European Parliament and of the Council laying down rules for the prevention, control, and eradication of certain transmissible spongiform encephalopathies, 2001 O.J. L 147 31.5). Further, the work by Pelletier et al. (2009) yielded data accounting for 70% of global farmed salmon feeds, and they reported a relatively small amount of poultry by-product use and no mammalian by-product use. Preference for wild fish inputs is also reflected in higher commodity prices for fish meal and oil (Naylor et al. 2009); commodity prices of fish meal increased four-fold between 1999 and 2015, although they have since declined (World Bank 2017).

It can be expected that, as inputs to fisheries are constrained by wild catch, and as the redirection of fish meal and oil away from livestock production and towards aquaculture reaches a limit, future production of salmonid feeds will need to rely on an increasing rate of alternative inputs to satisfy nutritional requirements. While this may not necessarily place an increased demand on total use of animal by-products, it may shift their use away from other functions and towards aquafeed production and as such provide an economic benefit to the source systems. It can be expected, then, that the upstream supply chains of fed aquaculture will increasingly include quantifiably energy- and emissions-intensive systems where previously much more efficient systems were relied upon. Even if demand for inputs is largely satisfied by redirection of fishery by-products rather than animal by-products, the environmental burden of those systems will still be greater than that of dedicated reduction fisheries (Cashion et al. 2017).

4.3 Methodological treatment of by-products

It is evident from the sensitivity analysis undertaken here that, in cases where high animal by-product inputs are included in the formulation of feeds, the method of allocating impact from the source production system is critical in determining the relative environmental impact attributed to both the feeds and the final product. Debate regarding which allocation method is more effective at conveying environmental realities and how standards and guidelines should recommend allocation be undertaken has been an ongoing theme in seafood LCA literature. An early overview of this debate was provided by Ayer et al. (2007), and arguments have since been made for the use of biophysical, economic, and consequential approaches.

Numerous studies have, at least in the case of feed inputs, opted to apply economic allocation (Papatryphon et al. 2004; Aubin et al. 2009). The rationale behind the use of economic allocation has been that it effectively places the majority of environmental burden on the product whose demand is driving production, and that the use of by-products has an environmental benefit by reducing pressure on other systems such as forage fisheries (Torrissen et al. 2011). Support for mass- and energy-based allocation, meanwhile, stems from the argument that biophysical allocation reflects the causal relationship between inputs and outputs, and thus it better represents the static biophysical realities of the systems assessed than would the use of dynamic and potentially misleading market-based information (Pelletier and Tyedmers 2011). For example, allocating based on nutritional energy content reflects the input of energy in the form of feed for animals or photosynthetically-captured energy for crops, and the output of energy in the form of feed and food; the nature of these relationships will remain relatively constant, while the economic value of the products may increase or decrease as supply and demand shift. Chen et al. (2017) carry this concept further and propose an adapted biophysical allocation method to reflect chemical demands of different animal tissues; while this method was not explored here, it may inform future analyses depending on the availability of data from relevant systems.

Consequential LCA is an additional approach which has been employed previously instead of direct allocation. This is essentially an extension of the concept of system expansion used here to credit the system based on avoided products (synthetic fertilizers). Proponents for consequential LCA argue that, because a product could be substituted with an alternative product, and therefore its use changes the demand—and production—of that alternative, the impact of the alternative product can be substituted into the system being assessed. Samuel-Fitwi et al. (2013a), for example, substitute the impact of soymeal production in the place of fish meal production, because soy meal is a marginal alternative product and thus the use of fish meal will increase the demand for, and production of, soy meal. While the concept of consequential LCA appears to provide opportunities to measure the real-world environmental effects of production within economic systems, and its basis in system expansion certainly has merit as prescribed by ISO (2006), application of consequential LCA presents several barriers when trying to quantify the absolute and relative environmental impacts of products. First, it relies on imperfect and incomplete information on present market conditions and rates of supply and demand either regionally or globally, and thus results are essentially nullified if these conditions change. Second, it fails to recognize the difference in actual impacts from systems producing the same by-products; fish meal from a highly efficient system, for example, would be applied the same impact as fish meal from a highly inefficient system because they can be substituted with the same product. Finally, the choice of substitution product lends considerable opportunity for bias. Using processes from the Agri-footprint database, for example, the substituted soy meal could have a vastly different impact whether the increase in production is assumed to occur in the United States or in Brazil, and given the limited amount of data available globally, the determination of an average product is likely to be highly subjective.

The current set of standards and guidelines available to LCA practitioners also do little to settle the debate regarding co-product allocation. The ISO (2006) standards recommend the avoidance of allocation using division of sub-systems or system expansion and subsequently allocation based on causal relationships between inputs and outputs, but they allow for any alternative basis for allocation as well. The PAS 2050-2 (BSI 2012) standard for measuring GHG emissions of seafood products recommends the use of mass-based allocation for foreground co-products but does not directly suggest allocation methods for feed inputs. The Aquaculture Stewardship Council Salmon Standard (ASC 2012), while requiring the accounting of GHG emissions from feed production, does not make any recommendation on allocation or the treatment of by-products in feeds. Guidelines from the Livestock Environmental Assessment and Performance Partnership (FAO 2016a) recommend the use of economic allocation when biophysical relationships cannot be determined, observing that “the price of feed materials seems to be generally correlated to their nutritional value”, but they do not explicitly address systems producing both feed and food products. Regardless of the method selected, standards and guidelines often encourage the use of sensitivity analysis to determine the effect of allocation choice and the provision of the results to inform readers—a recommendation not often followed in published aquaculture LCAs.

5 Conclusions

Tasmanian Atlantic salmon products were assessed using LCA up to the point of delivery to domestic markets in Australia, representing 40% of the Australian industry. Feed production was the primary driver of all impact categories for both salmon at farm-gate and HOG salmon at market. Animal by-product production in particular was the dominant source of energy use and emissions in the supply chain. The considerable rate of animal by-product inclusion in Tasmanian aquafeeds, coupled with high FCRs, resulted in a dramatically higher environmental burden than that observed in previous studies. The method of allocating impact from animal production systems between their direct-to-human consumption products and their intermediate by-products was identified as a key determinant of the modeled environmental burden of high by-product salmonid feeds and HOG salmon at market.

The treatment of by-products in salmonid and other aquafeeds by LCA practitioners is a critical aspect of how we interpret and report the current and future sustainability of a growing global seafood industry. Previously, because of the relatively small use of by-products in assessed systems, the impact of this decision, while evident, was not as clear as in the present study. From an industrial ecology perspective, it seems intuitive that we should not explicitly discourage the use of by-products as inputs when they are encouraged as outputs, the alternative being waste. Indeed, their use in aquafeeds would seem beneficial with regards to reliance on wild fish stocks. However, the source of by-products should be reflected in the impact of the studied supply chain and there should be environmental incentives given to the use of by-products (and indeed primary products) from highly efficient systems over those from high-impact systems. Opportunities to expand production of efficient inputs from reduction fisheries are limited, and animal by-products provide nutritional advantages over crop alternatives, making them a likely source for inputs to future aquaculture production. If, in a hypothetical future scenario, sustainable world food supply includes substantially reduced dependence on livestock production in order to fit within environmental capacities, then by-products from those systems cannot be relied upon as a sustainable source of inputs to a rapidly growing aquaculture industry. If animal production does expand, facilitating the demand for their by-products for multiple uses, that expansion will have a real environmental cost which should be borne by all consumers of the outputs. In this regard, recognition of the high impact associated with animal by-product use in aquaculture is not counter-productive to broader environmental goals but is rather reflective of the environmental reality of a transitioning global food production system.

References

ASC (2012) ASC salmon standard version 1.0. Aquaculture Stewardship Council. http://www.asc-aqua.org/upload/ASC%20Salmon%20Standard_v1.0.pdf. Accessed 22 December 2015

Aubin J, Papatryphon E, van der Werf HMG, Chatzifotis S (2009) Assessment of the environmental impact of carnivorous finfish production systems using life cycle assessment. J Clean Prod 17:354–361

Ayer N, Martin S, Dwyer RL, Gace L, Laurin L (2016) Environmental performance of copper-alloy net-pens: life cycle assessment of Atlantic salmon grow-out in copper-alloy and nylon net-pens. Aquaculture 453:93–103

Ayer NW, Tyedmers PH (2009) Assessing alternative aquaculture technologies: life cycle assessment of salmonid culture systems in Canada. J Clean Prod 17:362–373

Ayer NW, Tyedmers PH, Pelletier NL, Sonesson U, Scholz A (2007) Co-product allocation in life cycle assessments of seafood production systems: review of problems and strategies. Int J Life Cycle Assess 12:480–487

Boissy J, Aubin J, Drissi A, van der Werf HMG, Bell GJ, Kaushik SJ (2011) Environmental impacts of plant-based salmonid diets at feed and farm scales. Aquaculture 321:61–70

BSI (2012) PAS 2050-2: 2012—Assessment of life cycle greenhouse gas emissions: supplementary requirements for the application of PAS 2050:2011 to seafood and other aquatic food products. British Standards Institution, London

Carter CG, Hauler RC (2000) Fish meal replacement by plant meals in extruded feeds for Atlantic salmon, Salmo salar L. Aquaculture 185:299–311

Cashion T, Tyedmers P, Parker RWR (2017) Global reduction fisheries and their products in the context of sustainable limits. Fish Fish. doi:10.1111/faf.12222

Chen X, Wilfart A, Puillet L, Aubin J (2017) A new method of biophysical allocation in LCA of livestock co-products: modeling metabolic energy requirements of body-tissue growth. In J Life Cycle Assess 22:883–895

D’Orbcastel ER, Blancheton J, Aubin J (2009) Towards environmentally sustainable aquaculture: comparison between two trout farming systems using life cycle assessment. Aquac Eng 40:113–119

Dekamin M, Veisi H, Safari E, Liaghati H, Khoshbakht K, Dekamin MG (2015) Life cycle assessment for rainbow trout (Oncorhynchus mykiss) production systems: a case study for Iran. J Clean Prod 91:43–55

Driscoll J, Boyd C, Tyedmers P (2015) Life cycle assessment of the Maine and southwest Nova Scotia lobster industries. Fish Res 172: 385-400

Durlinger B, Tyszler, Scholten J, Broekema R, Blonk H (2014) Agri-footprint; a life cycle inventory database covering food and feed production and processing. Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-food Sector, 8–10 October, 2014, San Francisco, USA

Ellingsen H, Olaussen JO, Utne IB (2009) Environmental analysis of the Norwegian fishery and aquaculture industry—a preliminary study focusing on farmed salmon. Mar Policy 33:479–488

El-sayed AM (1999) Alternative dietary protein sources for farmed tilapia, Oreochromis spp. Aquaculture 179:149–168

FAO (2016a) Environmental performance of animal feeds supply chains: guidelines for assessment. Food and Agriculture Organization of the United Nations, Rome

FAO (2016b) The state of world fisheries and aquaculture: contributing to food security and nutrition for all. Food and Agriculture Organization of the United Nations, Rome

FAO (2016c) Food outlook: biannual report on global food markets. Food and Agriculture Organization of the United Nations, Rome

Fréon P, Avadí A, Soto W, Negrón R (2014) Environmentally extended comparison table of large- versus small- and medium-scale fisheries: the case of the Peruvian anchoveta fleet. Can J Fish Aquat 71: 1459- 1474

Geisler G, Hellweg S, Hungerbühler K (2005) Uncertainty analysis in life cycle assessment (LCA): Case study on plant-protection products and implications for decision making. Int J Life Cycle Assess 10: 184-192

Goedkeep M, Heijungs R, Huijbregts M, Dr Schryver A, Stuijs J, van Zelm R (2009) ReCiPe 2008: A life cycle impact assessment method which comprises harmonized category indicators at the midpoint and the endpoint level. Ministry of Housing, Spatial Planning and Environment, Netherlands

Grönroos J, Seppälä J, Silvenius F, Mäkinen T (2006) Life cycle assessment of Finnish cultivated rainbow trout. Boreal Environ Res 11:401–414

Guinée J (2001) Handbook on life cycle assessment—operational guide to the ISO standards. Int J Life Cycle Assess 6: 255.

Hardy R (1996) Alternate protein sources for salmon and trout diets. Anim Feed Sci Tech 59:71–80

Henriksson P, Guinée J, Heijungs R, de Koning A, Green D (2014) A protocol for horizontal averaging of unit process data—including estimates for uncertainty. Int J Life Cycle Assess 19:429–436

Henriksson P, Guinée J, Kleijn R, de Snoo G (2012) Life cycle assessment of aquaculture systems—a review of methodologies. Int J Life Cycle Assess 17:304–313

ISO (2006) ISO 14044: environmental management—life cycle assessment—requirements and guidelines. International Organization for Standardization, Geneva

McGrath KP, Pelletier NL, Tyedmers PH (2015) Life cycle assessment of a novel closed-containment salmon aquaculture technology. Environ Sci Technol 49:5628–5636

Millamena OM (2002) Replacement of fish meal by animal by-product meals in a practical diet for grow-out culture of grouper Epinephelus coioides. Aquaculture 204:75–84

Naylor RL, Hardy RW, Bureau DP, Chiu A, Elliott M, Farrell AP, Forster I, Gatlin DM, Goldburg RJ, Hua K, Nichols PD (2009) Feed aquaculture in an era of finite resources. P Natl Acad Sci USA 106:15103–15110

Papatryphon E, Petit J, Kaushik SJ, van der Werf HMG (2004) Environmental impact assessment of salmonid feeds using life cycle assessment (LCA). Ambio 33:316–323

Parker, RWR (2011) Measuring and characterizing the ecological footprint and life cycle environmental costs of Antarctic krill (Euphausia superba) products. Masters thesis, Dalhousie University, Halifax, Canada

Parker RWR, Tyedmers PH (2012) Life cycle environmental impacts of three products derived from wild-caught Antarctic krill (Euphausia superba). Env Sci Technol 46:4958–4965

Parker RWR, Tyedmers PH (2015) Fuel consumption of global fishing fleets: current understanding and knowledge gaps. Fish Fish 16:684–696

Pelletier N, Ayer N, Tyedmers P, Kruse S, Flysjo A, Robillard G, Zieglers F, Scholz A, Sonesson U (2007) Impact categories for life cycle assessment research of seafood production systems: review and prospectus. Int J Life Cycle Assess 12:414–421

Pelletier N, Tyedmers P (2007) Feeding farmed salmon: is organic better? Aquaculture 272:399–416

Pelletier N, Tyedmers P (2011) An ecological economic critique of the use of market information in life cycle assessment research. J Ind Ecol 15:342–354

Pelletier N, Tyedmers P, Sonesson U, Scholz A, Ziegler F, Flysjo A, Kruse S, Cancino B, Silverman H (2009) Not all salmon are created equal: life cycle assessment (LCA) of global salmon farming systems. Environ Sci Technol 43:8730–8736

PRé Consultants bv (2013) SimaPro life cycle assessment software package, version 8. PRé Consultants, Amersfoort, Netherlands.

S & P Global (2017) Portworld Distance Calculator. http://www.portworld.com/map

Samocha TM, Davis DA, Saoud IP, DeBault K (2004) Substitution of fish meal by co-extruded soybean poultry by-product meal in practical diets for the Pacific white shrimp, Litopenaeus vannamei. Aquaculture 231:197–203

Samuel-Fitwi B, Meyer S, Reckmann K, Schroeder JP, Schulz C (2013a) Aspiring for environmentally conscious aquafeed: comparative LCA of aquafeed manufacturing using different protein sources. J Clean Prod 52:225–233

Samuel-Fitwi B, Nagel F, Meyer S, Schroeder JP, Schulz C (2013b) Comparative life cycle assessment (LCA) of raising rainbow trout (Oncorhynchus mykiss) in different production systems. Aquac Eng 54:85–92

Savage J (2015) Australian fisheries and aquaculture statistics 2015. Fisheries Research and Development Corporation project 2016-246. ABARES, Canberra

Shepherd C, Jackson A (2013) Global fishmeal and fish-oil supply: inputs, outputs and markets. J Fish Biol 83:1046–1066

Steffens W (1994) Replacing fish meal with poultry by-product meal in diets for rainbow trout, Oncorhynchus mykiss. Aquaculture 124:27–34

Tacon AGJ, Metian M (2008) Global overview on the use of fish meal and fish oil in industrially compounded aquafeeds: trends and future prospects. Aquaculture 285:146–158

Torrissen O, Olsen RE, Toresen R, Hemre GI, Tacon AGJ, Asche F, Hardy RW, Lall S (2011) Atlantic salmon (Salmo salar): the “super-chicken” of the sea? Rev Fish Sci 19:257–278

van Putten I, Farmery A, Green B, Hobday A, Lim-Camacho L, Norman-López A, Parker R (2016) The environmental impact of two Australian rock lobster fishery supply chains under a changing climate. J Ind Ecol 20: 1384-1398

Weidema BP, Bauer C, Hischier R, Mutel C, Nemecek T, Reinhard J, Vadenbo CO, Wernet G (2013) Overview and methodology: data quality guideline for the ecoinvent database version 3. Ecoinvent report no. 1(v3). The ecoinvent Centre, St. Gallen, Switzerland

Weidemann S, McGahan E, Poad G (2012) Using life cycle assessment to quantify the environmental impact of chicken meat production. Rural Industries Research and Development Corporation, Canberra

Weidemann S, Yan M (2014) Livestock meat processing: inventory data and methods for handling co-production for major livestock species and meat products. Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-food Sector, 8–10 October, 2014, San Francisco, USA

White A (2013) A comprehensive analysis of efficiency in the Tasmanian salmon industry. PhD thesis, Bond University, Gold Coast, Australia

Winther U, Ziegler F, Hognes E, Emanuelsson A, Sund V, Ellingsen H (2009) Carbon footprint and energy use of Norwegian seafood products. SINTEF Fisheries and Aquaculture, Trondheim, Norway

World Bank (2012) Fish to 2030: prospects for fisheries and aquaculture. The World Bank, Washington D.C

World Bank (2017) World Bank commodities price data (The pink sheet). http://www.worldbank.org/commodities

Ytrestoyl T, Aas T, Berge G, Hatlen B, Sørensen M, Ruyter B, Thomassen M, Hognes E, Ziegler F, Sund V, Åsgård T (2011) Resource utilization and eco-efficiency of Norwegian salmon farming in 2010. Nofima, Tromsø, Norway

Ziegler F, Nilsson P, Mattsson B, Walther Y (2003) Life cycle assessment of frozen cod fillets including fishery-specific environmental impacts. Int J Life Cycle Assess 8:39–47

Acknowledgements

RP would like to acknowledge the support of the Natural Sciences and Engineering Resarch Council of Canada (NSERC), and thank those producers, suppliers, and others who provided data and assistance contributing to this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angel Avadí

Rights and permissions

About this article

Cite this article

Parker, R. Implications of high animal by-product feed inputs in life cycle assessments of farmed Atlantic salmon. Int J Life Cycle Assess 23, 982–994 (2018). https://doi.org/10.1007/s11367-017-1340-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1340-9