Abstract

Purpose

The food processing industry is a major consumer of energy and water, the consumption of which has environmental impacts. This work develops a method to determine process-specific water use and utilizes an existing energy use toolbox to calculate the energy and water required for each step of food processing. A life cycle assessment (LCA) is conducted to determine how much processing contributes to a particular product’s cradle to gate impacts for two impact categories.

Methods

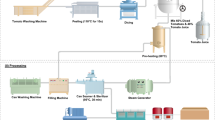

A method to determine water use at each unit process was developed, and in conjunction with an already developed energy use unit process toolbox, the methods were tested using two case studies. Processing data such as flow rates, operation temperatures, and food losses were used from two Swiss food production facilities. Calculation results were compared to measured facility data such as yearly energy and water use. Results were then used to develop LCAs for a total of seven food products, including five types of juice and two types of potato products.

Results and discussion

The toolboxes were able to calculate the water use of both facilities within 25%, the thermal energy use within 9%, and electricity use within 24%. Impacts from processing were particularly important for the potato products, particularly potato flakes, due to impacts stemming from thermal energy use. For juices, impacts due to raw material growth dominate the LCA, and impacts due to processing are much less significant. A unit process analysis may not be necessary when there is little variation in the unit processes between the different products. In this case, a simple allocation of measured facility energy and water data may be sufficient for calculating the impacts associated with processing. However, products with largely varying unit processes may have very different impacts. Impacts are sensitive to the type of energy required (thermal or electrical) and the sources of electricity and water.

Conclusions

These water and energy toolboxes can improve transparency in processing and identify the most water- and energy-intensive steps; however, in facilities with similar products, such an extensive analysis may not be necessary. Results from these calculations are useful in developing food product LCAs.

Similar content being viewed by others

References

Accorsi R, Versari L, Manzini R (2015) Glass vs. plastic: life cycle assessment of extra-virgin olive oil bottles across global supply chains. Sustainability 7:2818–2840

Berk Z (2009) Food process engineering and technology. Academic Press, Burlington

Boema. http://www.boema.com. Accessed 1 Feb 2016

BREF (2006) Reference document on the best available techniques in the food, drink and milk industries. European Commission, Seville

Buchli J (2013) Energiesparen durch Energiebenchmark. Zürcher Hochschule für Angewandte Wissenschaften. Inst für Leb und Getränkeinnovation Transfer Newsletter, Feb 2013

Camperos R, Nacheva M, Diaz T (2004) Treatment techniques for the recycling of bottle washing water in the soft drinks industry. Water Sci Technol 50:107–112

Canning P, Charles A, Huang S, Polenske K, Waters Arnold (2010). Energy use in the U.S. food system. United States Department of Agriculture Economic Research Report Number 24. Washington, DC

Cappelletti G, Ioppolo G, Nicoletti G, Russo C (2014) Energy requirement of extra virgin olive oil production. Sustainability 6:4966–4974

Carlsson-Kanyama A, Faist M (2000) Energy use in the food sector: a data survey. Environmental Strategies Research Group, Stockholm, Sweden. Retrieved from: http://citeseerx.ist.psu.edu/viewdoc/download?rep=rep1&type=pdf. Accessed 13 Jan 2015

Center for Food Safety and Applied Nutrition (U.S.) (1998) Guide to minimize microbial food safety hazards for fresh fruits and vegetables: guidance for industry. U.S. Dept. of Health and Human Services, Food and Drug Administration, Center for Food Safety and Applied Nutrition

Cleland DJ, Valentas KJ (1997) Prediction of freezing time and design of food freezers. In: Valentas K, Rotstein E, Singh RP (eds) Handbook of food engineering practice. CRC Press, Boca Raton, p 698

Colston NV, Smallwood C, Whitaker RS (1974) Waste control and abatement in the processing of sweet potatoes. Environmental Protection Technology Series December 1974, EPA-660/2-73-021. National Environmental Research Center Office of Research and Development U.S. Environmental Protection Agency, Corvalis, Oregon 97330. Downloaded from: https://nepis.epa.gov. Accessed 3 Sept 2015

Cooke P (2008) Legislation and economic issues regarding water and energy management in food processing. In: Klemes J, Kim J-K, Smith R (eds) Handbook of water and energy management in food processing. CRC Press, Boca Raton

East Bay Municipal Utility District (2008) Watersmart guidebook: a water-use efficiency plan, Review Guide for New Businesses. Retrieved from: http://www.ebmud.com/. Accessed 29 Jan 2015

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess 21(9):1218–1230. Available at http://link.springer.com/10.1007/s11367-016-1087-8. Accessed 21 Jan 2015

Fellows P (2009) Food processing technology principles and practices, 3nd edn. CRC Press, Boca Raton

Fulgoni VL, Keast DR, Drewnowski A (2009) Development and validation of the nutrient-rich foods index: a tool to measure nutritional quality of foods. J Nutr 139:1549–1554

Gil MI, Selma MV, López-Gálvez F, Allende A (2009) Fresh-cut product sanitation and wash water disinfection: problems and solutions. Int J Food Microbiol 134:37–45

Haroon H, Waseem A, Mahmood Q (2013) Treatment and reuse of wastewater from beverage industry. J Chem Soc Pak 35:5–10

Heller MC, Keoleian GA, Willett WC (2013) Toward a life cycle-based, diet-level framework for food environmental impact and nutritional quality assessment: a critical review. Environ Sci Technol 47:12632–12647

ILSI Europe Environmental and Health Task Force Report Series (2008). Considering water quality for use in the food industry. International Life Sciences Institute, Brussels Retrieved from: http://ilsi.org/publication/considering-water-quality-for-use-in-the-food-industry/

ILSI Research Foundation Center for Risk Science and Innovation Application (2013) Guideline for safe application of water conservation methods in beverage production and food processing: water recovery and reuse. Washington, D.C. Retrieved from: http://ilsi.org/publication/water-recovery-and-reuse-guidelines-for-safe-application-of-water-conservation-methods-in-beverage-production-and-food-processing/. Accessed 10 Aug 2015

International Dairy Federation (2010) Bulletin of the IDF N° 479/ 2015: A common carbon footprint approach for dairy: the IDF guide to standard lifecycle assessment methodology for the dairy sector. Retrieved from: http://store.fil-idf.org/product/a-common-carbon-footprint-approach-for-the-dairy-sector-the-idf-guide-to-standard-life-cycle-assessment-methodology/. Accessed 10 Aug 2015

IPCC (2006) 2006 IPCC Guidelines for National Greenhouse Gas Inventories. The National Greenhouse Gas Inventories Programme, The Intergovernmental Panel on Climate Change

James C, Purnell G, James SJ (2014) Seafood processing. In: Tiwari K, Norton T, Holden NM (eds) Sustainable food processing, 1st edn. John Wiley & Sons, Ltd, Chichester

Jeswani HK, Burkinshaw R, Azapagic A (2015) Environmental sustainability issues in the food-energy-water nexus: breakfast cereals and snacks. Sustain Prod Consum 2:17–28

Kader AA (2002) Postharvest technology of horticultural crops, 3rd edn. University of California Agriculture and Natural Resources. Publication 3529 ISBN-13:978-60107-743-1 Library of Congress Control Number: 2001087610 2011. The Regents of the University of California Agriculture and Natural Resources Richmond, CA

Kozempel ME, Sullivan JF, Craig JC (1985) Modelling and simulating commercial hot water blanching of potatoes. Am Potato J 62:69–82

Lehto M, Sipilä I, Alakukku L, Kymäläinen H (2014) Water consumption and wastewaters in fresh-cut vegetable production. Agric Food Sci 23:246–256

Marcotte M, Grabowski S (2008) Minimising energy consumption associated with drying, baking and evaporation. In: Klemes J, Smith R, Kim J (eds) Handbook of water and energy management in food processing. CRC Press Woodhead Publishing Limited, Cambridge

Masanet E (2008) Energy efficiency improvement and cost saving opportunities for the fruit and vegetable processing industry. An ENERGY STAR guide for energy and plant managers. Lawrence Berkeley National Laboratory. Retrieved from: https://escholarship.org/uc/item/8h25n5pr. Accessed 7 Jan 2015

Moerman F, Rizoulières P, Majoor FA (2014) Cleaning in place (CIP) in food processing. In: Lelieveld HLM, Holah JT, Napper D (eds) Hygiene in food processing principles and practice, Second. Woodhead Publishing Limited, Cambridge

Nemecek T, Bengoa X, Lansche J, Mouron P, Rossi V, Humbert S (2014) Methodological guidelines for the life cycle inventory of agricultural products. Version 2.0, July 2014. World Food LCA Database (WFLDB). Quantis and Agroscope, Lausanne and Zurich

Notarnicola B, Salomone R, Petti L et al (eds) (2015) Life cycle assessment in the agri-food sector: case studies, methodological issues and best practices. Springer, London

Okos M, Rao N, Drecher S, Rode M, Kozak J (1998) Energy use in the food industry. American council for an energy-efficient economy. Retrieved from: http://aceee.org/research-report/ie981. Accessed 23 Jan 2015

Ölmez H (2014) Water consumption, reuse and reduction strategies in food processing. In: Tiwari BK, Norton T, Holden NM (eds) Sustainable food processing. John Wiley & Sons, Ltd, Chichester, pp 401–434

Ozilgen M (1998) Handbook of food process modeling and statistical quality control. CRC Press Taylor & Francis Group, Boca Raton

Pardo G, Zufía J (2012) Life cycle assessment of food-preservation technologies. J Clean Prod 28:198–207

Pfister S, Koehler A, Hellweg S (2009) Assessing the environmental impacts of freshwater consumption in LCA. Environ Sci Technol 43:4098–4104

Reddy MB, Love M (1999) The impact of food processing on the nutritional quality of vitamins and minerals. In: Jackson et al. (eds) Impact of processing on food safety. Kluwer Academic, Plenum Publishers, New York

Ridoutt BG, Pfister S (2013) A new water footprint calculation method integrating consumptive and degradative water use into a single stand-alone weighted indicator. Int J Life Cycle Assess 18:204–207

Roy P, Nei D, Orikasa T et al (2009) A review of life cycle assessment (LCA) on some food products. J Food Eng 90:1–10

Sanjuán N, Ribal J, Clemente G, Fenollosa ML (2011) Measuring and improving eco-efficiency using data envelopment analysis: a case study of Menorca cheese. J Ind Ecol 15:614–628

Sanjuán N, Stoessel F, Hellweg S (2014) Closing data gaps for LCA of food products: estimating the energy demand of food processing. Environ Sci Technol 48:1132–1140

Singh RP (1987) Energy in food processing. In: Energy in world agriculture series, 1st edn. Elsevier Science, Amsterdam

Sinha N (2012) Handbook of fruits and fruit processing, 2nd edn. Wiley-Blackwell, Ames, Iowa, USA, West Sussex, UK, and Oxford, UK

SPX White Paper (2013) CIP and sanitation of process plant. Document ID: 22003-05-02-2013-GB Retrieved from: http://www.spxflow.com/en/assets/pdf/CIP_Systems_22003_05_02_2013_GB_tcm11-7665.pdf. Accessed 10 Aug 2015

Stoessel F, Juraske R, Pfister S, Hellweg S (2012) Life cycle inventory and carbon and water foodprint of fruits and vegetables: application to a Swiss retailer. Environ Sci Technol 46:3253–3262

Tokos H, Glavič P (2007) Minimisation of freshwater consumption in brewery. University of Maribor, Chemical Engineering Department, Slovenia. Retrieved from: http://folk.ntnu.no/skoge/prost/proceedings/icheap8-pres07/pres07webpapers/93%20Tokos.pdf. Accessed 10 Aug 2015

Vionnet S, Lessard L, Offutt A et al (2012) Quantis water database technical report

Wang L (2008) Energy efficiency and management in food processing facilities. CRC Press Taylor & Francis Group, Boca Raton

Wild Y (2008) Container handbook. Cargo loss prevention information from German marine insurers. www.containerhandbuch.de/chb_e/index.html. Accessed 1 Dec 2014

US Department of Agriculture (2015) Agricultural Research Service, Nutrient Data Laboratory. USDA National Nutrient Database for Standard Reference, Release 28. Version Current: September 2015. Internet:/nea/bhnrc/ndl https://www.ars.usda.gov/nea/bhnrc/ndl. Accessed May 2016

Acknowledgements

We thank the two facilities for offering their data, time, and knowledge in order to build the case studies and ETH Zurich for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Serenella Sala

Electronic supplementary material

ESM 1

(DOCX 370 kb)

Rights and permissions

About this article

Cite this article

Walker, C., Beretta, C., Sanjuán, N. et al. Calculating the energy and water use in food processing and assessing the resulting impacts. Int J Life Cycle Assess 23, 824–839 (2018). https://doi.org/10.1007/s11367-017-1327-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1327-6