Abstract

Purpose

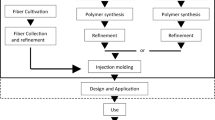

Biopolymers are considered to be environmentally friendlier than petroleum-based polymers, but little is known about their environmental performance against petroleum-based products. This paper presents the results of a life cycle assessment (LCA) of two prototype biocomposite formulations produced by extrusion of wood fibre with either polylactic acid (PLA) or a blend of PLA and locally produced thermoplastic starch (TPS).

Methods

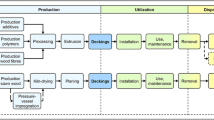

The study followed the LCA methodology outlined in the two standards set out by the International Organization for Standardization (ISO): ISO 14040 and ISO 14044 of 2006. A life cycle inventory (LCI) for the biocomposite formulations was developed, and a contribution analysis was performed to identify the significant inputs. Environmental performances of the two formulations were then compared with each other and polypropylene (PP), a petroleum-based polymer. The US Environmental Protection Agency’s impact assessment method, “TRACI: The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts”, was combined with Cumulative Energy Demand (a European method) in order to characterize the inventory flows. Environmental impact categories chosen for the analysis were the following: global warming, stratospheric ozone depletion, acidification of land and water, eutrophication, smog, human health (respiratory, carcinogenic, and non-carcinogenic) effects and ecotoxicity.

Results and discussion

We found that PLA is the significant input which contributes mostly to fossil fuel consumption, acidification and respiratory and smog effects. Impacts from PLA transport from the faraway source significantly added more burden to its contributions. TPS causes less environmental burden compared to PLA; the environmental performance of the biocomposite improved when a blend of PLA and TPS is used in formulating the biocomposite. The two formulations performed better than PP in all the environmental impact categories except eutrophication effects, which is important on a regional basis.

Conclusions

The following conclusions were drawn from this study:

-

PLA is the environmentally significant input among the three raw materials.

-

TPS causes less environmental burden than PLA. Environmental performance of the biocomposite improves in the life cycle energy consumption, fossil energy use, ozone depletion and non-carcinogenic impact categories when a blend of PLA and TPS is used.

-

The biocomposite can outperform PP in all the impact categories except eutrophication effects if manufactured using hydroelectricity.

The biopolymer could be a potential alternative to PP as it could cause less of a burden to the environment on a cradle-to-gate basis. Environmental impacts at the complete life cycle levels should be looked into in order to fully understand its potential.

Similar content being viewed by others

References

Almeras X, Le Bras M, Hornsby P, Bourbigot S, Gy M, Keszei S, Poutch F (2003) Effect of fillers on the fire retardancy of intumescent PP compounds. Polym Degrad Stabil 82(2):325–331

Assamoi B, Lawryshyn Y (2012) The environmental comparison of landfilling vs. incineration of municipal solid waste accounting for waste diversion. Waste Manage 32:1019–1030

ASTM D 5229/D5229M-92 (Reapproved 2004), Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials

ASTM D256-10, Standard test methods for determining the Izod pendulum impact resistance of plastics

ASTM D5338-98 (Reapproved 2003), Standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions

ASTM D570-98 (Reapproved 2005), Standard test method for water absorption of plastics

ASTM D638-10, Standard test methods for tensile properties of plastics

Athena Institute (2009a) A cradle-to-gate life cycle assessment of Canadian softwood lumber. Ottawa. http://www.athenasmi.org/publications/docs/CIPEC_Lumber_LCA_Final_Report.pdf

Athena Institute (2009b) A cradle-to-gate life cycle assessment of Canadian medium density fiber board. Ottawa. http://www.athenasmi.org/publications/docs/CIPEC_Canadian_MDF_LCA_final_report.pdf

Butylina S, Hyvarinen M, Karki T (2012) Accelerated weathering of wood-polypropylene composites containing minerals. Composites Part A: Appl Sci & Manuf 43(11):2087–2094

Diagne M, Gueye M, Vidal L, Tidjani A (2005) Thermal stability and fire retardant performance of photo-oxidized nanocomposites of PP-grafted-maleic anhydride/clay. Polym Degrad Stabil 89(3):418–426

Hermann GH, Blok K, Patel MK (2010) Twisting biomaterials around your little finger: environmental impacts of bio-based wrappings. Int J Life Cycle Assess 15(4):346–358

ISO 14040 (2006) Environmental management—life cycle assessment—principles and framework

ISO 14044 (2006) Environmental management—life cycle assessment—requirements and guidelines

Legros N, Mihai M, Iordan A, Alemdar A (2011) Wood fibers reinforced PLA and PLA/TPS biocomposites: processing, formulation and mechanical properties 3rd International Conference on Biodegradable and Biobased Polymers, BioPol

Mihai M, LegrosN, Iordan A, Alemdar A (2011) New wood fiber biocomposites based on polylactide and polylactide/thermoplastic starch blends. From Annual Technical Conference—Society of Plastics Engineers, 69th (2):1065–1071

Mihai M, Legros N, Alemdar A (2012) Wood fiber biocomposites based on polylactic acid and its blends with thermoplastic starch, Polymer Processing Society—PPS Americas Conference

Mihai M, Legros N, Alemdar A (2013) Formulation-properties versatility of wood fiber biocomposites based on polylactide and polylactide/thermoplastic starch blends. Polymer Eng & Sci. doi:10.1002/PEN.23681

Sain M, Balatinecz J, Law S (2000) Creep fatigue in engineered wood fibre and plastic compositions. J Appl Sci 77:260–268

Skog K (2008) Sequestration of carbon in harvested wood products for the United States. Forest Prod J 58:56–72

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Holger Wallbaum

Rights and permissions

About this article

Cite this article

Mahalle, L., Alemdar, A., Mihai, M. et al. A cradle-to-gate life cycle assessment of wood fibre-reinforced polylactic acid (PLA) and polylactic acid/thermoplastic starch (PLA/TPS) biocomposites. Int J Life Cycle Assess 19, 1305–1315 (2014). https://doi.org/10.1007/s11367-014-0731-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-014-0731-4