Abstract

Purpose

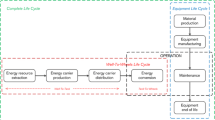

The goal of this study is to develop an estimate of water use and consumption in automotive manufacturing to enhance the data quality of vehicle life cycle assessments that include life cycle water impacts. A benchmark is developed to compare water resources across manufacturing and nonproduction-related manufacturing processes, including an indication whether indirect water consumption due to electricity generation is significant.

Methods

Data from 12 original equipment manufacturers’ (OEM’s) sustainability reports are examined for the years 2006 to 2010. Distinctions are made between “water use” and “water consumption.” These factors are divided by total reported production to develop use and consumption values in cubic meter/vehicle for comparison. Additionally, total energy consumption is converted to indirect water consumption based on the water consumed in the generation of electricity for the electricity grid mix.

Results and discussion

Excluding outliers, average direct water use is 5.20 and 5.95 m3/vehicle for manufacturing and company-wide activities, respectively, with corresponding standard deviations of 1.42 and 1.20 m3/vehicle. Average direct water consumption was calculated to be 1.25 and 4.29 m3/vehicle for manufacturing and company-wide activities, respectively, with corresponding standard deviations of 0.52 and 1.56 m3/vehicle. Average indirect water consumption due to electricity consumption is found to be 2.21 m3/vehicle. Variability arises through different understandings on the words “consumption” and “use,” reporting continuity between years and in classification of data as it relates to manufacturing, nonmanufacturing, or company-wide activities.

Conclusions

These water values show that needs vary widely across OEMs. Additionally, the magnitude of the indirect water consumption results indicates that OEMs should focus on both indirect and direct water consumption to reduce their overall water footprint. The results also highlight the potential for significance and variability in indirect water consumption, in particular for “cradle-to-gate” type of impact assessments, dependent on electricity generation water consumption assumptions. It is hoped that with the introduction of water reporting standards like the International Organization of Standardization 14046, manufacturers will provide a more comprehensive summary of their water use and consumption in the future.

Similar content being viewed by others

Abbreviations

- LCA:

-

Life cycle assessment

- OEM:

-

Original equipment manufacturer

- ISO:

-

International Organization of Standardization

- VMA:

-

Vehicle manufacturing and assembly

References

Berger M, Warsen J, Krinke S, Bach V, Finkbeiner M (2012) Water footprint of European cars: potential impacts of water consumption along automobile life cycles. Environ Sci Technol 46:4091–4099

Blackhurst M, Hendrickson C, Sels I, Vidal J (2010) Direct and indirect water withdrawals for U.S. industrial sectors. Environ Sci Technol 44:2126–2130

BMW Group (2010) Sustainability value report 2010. Bayerische Motoren Werke, AG, Munich

BMW Group (2011) Annual report 2010. Bayerische Motoren Works, Munich

EIA (2011) International energy outlook 2011. EIA, Washington, DC

Feeley TJ III, Skone TJ, Stiegel GJ Jr, McNemar A, Nemeth M, Schimmoller B, Murphy JT, Manfredo L (2008) Water: a critical resource in the thermoelectric power industry. Energy 33(1):1–11

Fthenakis V, Kim HC (2010) Life-cycle uses of water in U.S. electricity generation. Renew Sust Energ Rev 14(7):2039–2048

General Motors Company (2011) Sustainability in motion: general motors sustainability report. General Motors Company, Detroit

Gleick PH (1994) Water and energy. Annu Rev Energ Env 19(1):267–299

Harto C, Meyers R, Williams E (2010) Life cycle water use of low-carbon transport fuels. Energ Policy 38(9):4933–4944

Honda (2011) Global environmental impact. http://world.honda.com/environment/currentinitiatives/impact.html. Accessed 15 Nov 2011

ISO (2011) ISO14046 water footprint working draft 2.1-17. ISO, Geneva

Mazda Motor Corporation (2011) Sustainability report 2011. CSR and Environment Department, Hiroshima

Owens JW (2002) Water resources in life-cycle impact assessment. J Ind Ecol 5(2):37–54

Pfister S, Koehler A, Hellweg S (2009) Assessing the environmental impacts of freshwater consumption in LCA. Environ Sci Technol 43(11):4098–4104

Raimbault M, Humbert S (2011) ISO considers potential standard on water footprint. International Organization for Standardization. http://www.iso.org/iso/isofocusplus_bonus_water-footprint. Accessed February 18 2012

Schweimer GW, Levin M (2000) Sachbilanz des Golf A4 (life cycle inventory for the Golf A4). Volkswagen AG, Wolfsburg

Sullivan JL, Burnham A, Wang M (2010) Energy-consumption and carbon-emission analysis of vehicle and component manufacturing (trans: Division ES). Argonne National Laboratory, Argonne

Tejada F, Bras B, Guldberg T (2012a) Direct and indirect water consumption in vehicle manufacturing. In: ASME 2012 international design engineering technical conferences and computers and information in engineering conference, Chicago, IL

Tejada F, Zullo J, Yen J, Guldberg T, Bras B (2012b) Quantifying the life cycle water consumption of a passenger vehicle. In: Proceedings of 2012 SAE world congress conference and exposition. SAE International, Troy

Torcellini P, Long N, Judkoff R (2003) Consumptive water use for U.S. power production. National Renewable Energy Laboratory, Golden

Wu M, Peng MJ (2011) Developing a tool to estimate water use in electric power generation in the United States (trans: Division ES). Argonne National Laboratory, Argonne

Yen J, Bras B (2012) A system model for assessing vehicle use-phase water consumption in urban mobility networks. Energ Policy 51:474–492

Acknowledgments

The material presented in this manuscript is based on research done within the Sustainable Design and Manufacturing Program of the Manufacturing Research Center at the Georgia Institute of Technology. The authors would like to thank all those who have contributed their invaluable input and support, including but not limited to David Berdish, Thomas Niemann, Tim Wallington, Sherry Mueller, Hyung Chul Kim, and Wulf-Peter Schmidt from the Ford Motor Company.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Adriana Del Borghi

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 65.8 kb)

Rights and permissions

About this article

Cite this article

Semmens, J., Bras, B. & Guldberg, T. Vehicle manufacturing water use and consumption: an analysis based on data in automotive manufacturers’ sustainability reports. Int J Life Cycle Assess 19, 246–256 (2014). https://doi.org/10.1007/s11367-013-0612-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-013-0612-2