Abstract

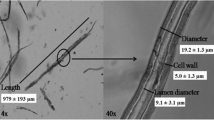

This study investigates the effects of CO2 curing on oriented cement-bonded boards. The boards comprised 35% and 45% (by mass) of strand-type particles of Eucalyptus spp. (8 × 2 × 0.1 cm) and 65% and 55% (by mass) of early high-strength Portland cement. To fabricate the boards, three layers of strands were arranged perpendicular to the previous layer, aiming for a target density of 1250 kg/m3, and the dimensions of the boards were 40 × 40 × 1 cm. The oriented cement-bonded boards underwent three different curing conditions: control, CO2 curing for 6 h, and 12 h, followed by curing in a saturated environment until the 28th day. The results indicated that CO2 curing increased the CaCO3 content in the boards, particularly when the curing period was longer (12 h). The physical and mechanical performance of the CO2-cured boards surpassed that of the control boards, with the modulus of rupture (MOR) increasing by 80% (6 h) and 84% (12 h) compared to the control. Scanning electron microscope investigations revealed that CO2 curing produced a denser matrix, leading to an improved bond between the strands and the matrix, resulting in enhanced technical performance. Based on these findings, this study suggests that CO2 curing can enhance the physical and mechanical properties of oriented cement-bonded boards, and a longer curing time (12 h) yielded superior performance.

Similar content being viewed by others

References

Almeida AEFS, Tonoli GHD, Santos SF, Savastano H (2013) Improved durability of vegetable fiber reinforced cement composite subject to accelerated carbonation at early age. Cem Concr Compos 42:49–58. https://doi.org/10.1016/j.cemconcomp.2013.05.001

Amziane S, Sonebi M (2016) Overview on biobased building material made with plant aggregate. RILEM Tech Lett 1:31. https://doi.org/10.21809/rilemtechlett.2016.9

ASTM International (2011) ASTM C150–04: standard specification for Portland cement. Am Soc Test Mater 04:1–7. https://doi.org/10.1002/jbm.b.31853

Auroy M, Poyet S, Le Bescop P et al (2018) Comparison between natural and accelerated carbonation (3% CO2): impact on mineralogy, microstructure, water retention and cracking. Cem Concr Res 109:64–80. https://doi.org/10.1016/J.CEMCONRES.2018.04.012

Benhelal E, Shamsaei E, Rashid MI (2021) Challenges against CO2 abatement strategies in cement industry: a review. J Environ Sci 104:84–101. https://doi.org/10.1016/J.JES.2020.11.020

Borges PHR, Costa JO, Milestone NB et al (2010) Carbonation of CH and C-S–H in composite cement pastes containing high amounts of BFS. Cem Concr Res 40:284–292. https://doi.org/10.1016/j.cemconres.2009.10.020

Borges PHR, Milestone NB, Costa JO et al (2012) Carbonation durability of blended cement pastes used for waste encapsulation. Mater Struct 45:663–678. https://doi.org/10.1617/s11527-011-9788-8

Brazilian Standard Technical Norms (1991) NBR 5733. High initial strength Portland cement, Rio de Janeiro

Cabral MR, Nakanishi EY, Fiorelli J (2017) Evaluation of the effect of accelerated carbonation in cement–bagasse panels after cycles of wetting and drying. J Mater Civ Eng 29. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001861

Cabral MR, Nakanishi EY, dos Santos V et al (2018a) Evaluation of accelerated carbonation curing in cement-bonded balsa particleboard. Mater Struct/Mater Constr 51. https://doi.org/10.1617/s11527-018-1179-y

Cabral MR, Nakanishi EY, Mármol G et al (2018b) Potential of Jerusalem artichoke (Helianthus tuberosus L.) stalks to produce cement-bonded particleboards. Ind Crops Prod 122:214–222. https://doi.org/10.1016/j.indcrop.2018.05.054

Cabral MRMR, Nakanishi EYEY, dos Santos V et al (2018c) Evaluation of pre-treatment efficiency on sugarcane bagasse fibers for the production of cement composites. Arch Civ Mech Eng 18:1092–1102. https://doi.org/10.1016/J.ACME.2018.02.012

Cabral MRMR, Nakanishi EYEY, dos Santos V et al (2018d) Evaluation of accelerated carbonation curing in cement-bonded balsa particleboard. Mater Struct 51:52. https://doi.org/10.1617/s11527-018-1179-y

Cabral MRMR, Nakanishi EYEY, Fiorelli J et al (2018e) Cement-bonded panels produced with sugarcane bagasse cured by accelerated carbonation. J Mater Civ Eng 30:04018103. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002301

Cabral MR, Nakanishi EY, Franco MSR et al (2020a) Treatments of residual pine strands: characterization and wood-cement-compatibility. J Wood Chem Technol. https://doi.org/10.1080/02773813.2020.1828474

Cabral MR, Nakanishi EY, Santos SF, Fiorelli J (2020b) Painéis cimento-madeira com lascas de madeira orientadas em camadas cruzadas e processo de fabricação dos painéis. 2020, Brazil. Patent: Innovation Privilege. Register number: BR1020200063103, Registration institution: INPI - National Institute of Industrial Property. Deposit: 27/03/2020. (In Portuguese)

Cabral MR, Nakanishi EY, Santos SF et al (2021) Orientation effect on the physical and mechanical properties of strand cement boards. Constr Build Mater 275:122121. https://doi.org/10.1016/J.CONBUILDMAT.2020.122121

Chen KW, Pan SY, Chen CT et al (2016) High-gravity carbonation of basic oxygen furnace slag for CO2 fixation and utilization in blended cement. J Clean Prod 124:350–360. https://doi.org/10.1016/J.JCLEPRO.2016.02.072

EN 323 (1993) Wood-based panels-determination of density. CEN, European Committee for Standardization, Brussels, Belgium

EN 317 (1993) Particleboards and fibreboards-determination of swelling in thickness after immersion in water. CEN, European Committee for Standardization, Brussels, Belgium

EN 300 (2006) Oriented Strand Boards (OSB). Definitions, classification and specifications; European Committee for Standartion, Brussels, Belgium

Fernández Bertos M, Simons SJR, Hills CD, Carey PJ (2004) A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2. J Hazard Mater 112:193–205. https://doi.org/10.1016/j.jhazmat.2004.04.019

Ferreira AM, Vikulina AS, Volodkin D (2020) CaCO3 crystals as versatile carriers for controlled delivery of antimicrobials. J Control Release 328:470–489. https://doi.org/10.1016/J.JCONREL.2020.08.061

Filomeno RH, Rodier LB, Ballesteros JEM et al (2020) Optimizing the modified atmosphere parameters in the carbonation process for improved fiber-cement performance. Journal of Building Engineering 32:101676. https://doi.org/10.1016/J.JOBE.2020.101676

Frybort S, Mauritz R, Teischinger A, Müller U (2012) Investigation of mechanical interaction at the interface of wood-cement composites by means of electronic speckle pattern interferometry. Biosourcescom 7:2483–2495

Govin A, Peschard A, Guyonnet R (2006) Modification of cement hydration at early ages by natural and heated wood. Cem Concr Compos 28:12–20. https://doi.org/10.1016/j.cemconcomp.2005.09.002

He P, Shi C, Tu Z et al (2016) Effect of further water curing on compressive strength and microstructure of CO2-cured concrete. Cem Concr Compos 72:80–88. https://doi.org/10.1016/J.CEMCONCOMP.2016.05.026

Hewlett PC (2013) Lea’s chemistry of cement and concrete

ISO 8335 (1987) Cement-bonded particleboards—boards of Portland or equivalent cement reinforced with fibrous wood particles. Switzerland

Iwakiri S, Moreira Da Silva JR, Lúcia S et al (2001) Produção de chapas de madeira aglomerada de cinco espécies de pinus tropicais. Floresta Ambiente 7:137–142

Kundu SP, Chakraborty S, Majumder SB, Adhikari B (2018) Effectiveness of the mild alkali and dilute polymer modification in controlling the durability of jute fibre in alkaline cement medium. Constr Build Mater 174:330–342. https://doi.org/10.1016/J.CONBUILDMAT.2018.04.134

Lenth RV (2009) Response-surface methods in R, using rsm. J Stat Softw 32. https://doi.org/10.18637/jss.v032.i07

Liu Z, Meng W (2021) Fundamental understanding of carbonation curing and durability of carbonation-cured cement-based composites: a review. J CO2 Utilization 44:101428. https://doi.org/10.1016/J.JCOU.2020.101428

Lu B, He P, Liu J et al (2021) Microstructure of Portland cement paste subjected to different CO2 concentrations and further water curing. J CO2 Utilization 53:101714. https://doi.org/10.1016/J.JCOU.2021.101714

Lu B, Huo Z, Xu Q et al (2023) Characteristics of CSH under carbonation and its effects on the hydration and microstructure of cement paste. Constr Build Mater 364:129952. https://doi.org/10.1016/J.CONBUILDMAT.2022.129952

Mármol G, Mattoso L, Correa AC et al (2020) Influence of cellulose pulp on the hydration followed by fast carbonation of MgO-based binders. J CO2 Utilization 41:101236. https://doi.org/10.1016/J.JCOU.2020.101236

Mohr BJ, Biernacki JJ, Kurtis KE (2007) Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem Concr Res 37:1531–1543. https://doi.org/10.1016/j.cemconres.2007.08.001

Odeyemi SO, Abdulwahab R, Adeniyi AG, Atoyebi OD (2020) Physical and mechanical properties of cement-bonded particle board produced from African balsam tree (Populous balsamifera) and periwinkle shell residues. Results Eng 6:100126. https://doi.org/10.1016/j.rineng.2020.100126

Pan X, Shi Z, Shi C et al (2017) A review on concrete surface treatment part I: types and mechanisms. Constr Build Mater 132:578–590. https://doi.org/10.1016/J.CONBUILDMAT.2016.12.025

Pipilikaki P, Papageorgiou D, Teas C et al (2008) The effect of temperature on thaumasite formation. Cem Concr Compos 30:964–969. https://doi.org/10.1016/j.cemconcomp.2008.09.004

Pizzol VDD, Mendes LMM, Frezzatti L et al (2014) Effect of accelerated carbonation on the microstructure and physical properties of hybrid fiber-cement composites. Miner Eng 59:101–106. https://doi.org/10.1016/j.mineng.2013.11.007

Rostami V, Shao Y, Boyd AJ, He Z (2012) Microstructure of cement paste subject to early carbonation curing. Cem Concr Res 42:186–193. https://doi.org/10.1016/j.cemconres.2011.09.010

Santos SF, Schmidt R, Almeida AEFS et al (2015a) Supercritical carbonation treatment on extruded fibre-cement reinforced with vegetable fibres. Cem Concr Compos 56:84–94. https://doi.org/10.1016/j.cemconcomp.2014.11.007

Santos SF, Schmidt R, Almeida AEFS et al (2015b) Supercritical carbonation treatment on extruded fibre–cement reinforced with vegetable fibres. Cem Concr Compos 56:84–94. https://doi.org/10.1016/j.cemconcomp.2014.11.007

Savastano H, Warden PG, Coutts RSP (2000) Brazilian waste fibres as reinforcement for cement-based composites. Cem Concr Compos 22:379–384. https://doi.org/10.1016/S0958-9465(00)00034-2

Scrivener K, Snellings R, Lothenbach B (2016) A practical guide to microstructural analysis of cementitious materials. CRC Press, Boca Raton, FL

Taylor HFW (1997) Cement chemistry. ThomasTelford, London

Tonoli GHDHD, Rodrigues Filho UPP, Savastano H et al (2009) Cellulose modified fibres in cement based composites. Compos Part A Appl Sci Manuf 40:2046–2053. https://doi.org/10.1016/j.compositesa.2009.09.016

Tonoli GHD, Santos SF, Joaquim AP, Savastano H (2010) Effect of accelerated carbonation on cementitious roofing tiles reinforced with lignocellulosic fibre. Constr Build Mater 24:193–201. https://doi.org/10.1016/j.conbuildmat.2007.11.018

Tonoli GHD, Pizzol VD, Urrea G et al (2016) Rationalizing the impact of aging on fiber–matrix interface and stability of cement-based composites submitted to carbonation at early ages. J Mater Sci 51:7929–7943. https://doi.org/10.1007/s10853-016-0060-z

Wang Y, Lu B, Hu X et al (2021) Effect of CO2 surface treatment on penetrability and microstructure of cement-fly ash–slag ternary concrete. Cem Concr Compos 123:104194. https://doi.org/10.1016/J.CEMCONCOMP.2021.104194

Wei J, Meyer C (2014) Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl Surf Sci 289:511–523. https://doi.org/10.1016/j.apsusc.2013.11.024

Wu F, You X, Wang M et al (2023) Increasing flexural strength of CO2 cured cement paste by CaCO3 polymorph control. Cem Concr Compos 141:105128. https://doi.org/10.1016/J.CEMCONCOMP.2023.105128

Zhang Q, Feng P, Shen X et al (2023) Utilization of solid wastes to sequestrate carbon dioxide in cement-based materials and methods to improve carbonation degree: a review. J CO2 Utilization 72:102502. https://doi.org/10.1016/J.JCOU.2023.102502

Zukowski B, dos Santos ERF, dos Santos Mendonça YG et al (2018) The durability of SHCC with alkali treated curaua fiber exposed to natural weathering. Cem Concr Compos 94:116–125. https://doi.org/10.1016/J.CEMCONCOMP.2018.09.002

Acknowledgements

The authors sincerely thank the facilities provided by the Research Nucleus on Materials for Biosystems (BioSMat) and the Laboratory of Structural Characterization at the Federal University of São Carlos for providing electron microscopy facilities.

Funding

This includes support from the Coordination for the Improvement of Higher Education Personnel (CAPES, Brazil), the São Paulo Research Foundation (FAPESP) through Grant # 2016/07372–9, and the National Council for Scientific and Technological Development (CNPq) via Grant # 312151/2016–0.

Author information

Authors and Affiliations

Contributions

MRC: conceptualization, methodology, investigation, validation, writing—original draft, writing—review and editing. EYN: conceptualization, methodology, investigation, validation, writing—review and editing. SFS: writing—review and editing, supervision, project administration. JF: resources, writing—review and editing, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cabral, M.R., Nakanishi, E.Y., Santos, S.F. et al. Enhancement of oriented cement-bonded boards’ properties through CO2 curing. Environ Sci Pollut Res 30, 117214–117224 (2023). https://doi.org/10.1007/s11356-023-30455-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-30455-2