Abstract

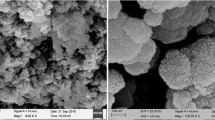

In this study, a kind of CexFeyOz composite with oxygen vacancy structure and strong oxygen storage capacity was prepared by coprecipitation method. Under the condition of no HCl of flue gas, the Hg0 in the flue gas of cement kiln was efficiently and economically removed by using 6–8% oxygen. The results showed that the optimum preparation conditions of the catalyst were Ce-Fe molar ratio of 1–11 and calcination temperature of 550 °C. In addition, the reaction temperature, space velocity, the concentration of O2, SO2, and NO had significant effects on the removal efficiency of Hg0 at different rates. More precisely, at the reaction temperature of 350 °C, low airspeed, high concentration of O2, and low concentration of SO2 and NO, the efficiency reached the highest value. According to XPS results, the elemental valence of the CexFeyOz composite changed after the reaction. The redox pairs of Ce3+-Ce4+ and Fe3+-Fe2+ had the ability to transfer electrons, which enabled more oxygen adsorbed on the catalyst surface to be converted into O2−, leading to the improvement of the oxidation efficiency of Hg0.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

An D, Sun X, Cheng X, Cui L, Zhang X, Zhao Y, Dong Y (2020) Investigation on mercury removal and recovery based on enhanced adsorption by activated coke. J Hazard Mater 384:121354

Cai X, Cai B, Zhang H, Chen L, Zheng C, Tong P, Wang X (2020) Establishment of high-resolution atmospheric mercury emission inventories for Chinese cement plants based on the mass balance method. Environ Sci Technol 54(21):13399–13408

Chen W, Pei Y, Huang W, Qu Z, Hu X, Yan N (2016) Novel effective catalyst for elemental mercury removal from coal-fired flue gas and the mechanism investigation. Environ Sci Technol 50(5):2564–2572

Chen Y, Guo X, Wu F (2020) Development and evaluation of magnetic iron-carbon sorbents for mercury removal in coal combustion flue gas. J Energy Inst 93(4):1615–1623

Coasne B, Grosman A, Ortega C, Simon M (2002) Adsorption in noninterconnected pores open at one or at both ends: a reconsideration of the origin of the hysteresis phenomenon. Phys Rev Lett 88(25):256102

Dastidar MG, Bhattacharyya A, Sarkar BK, Dey R, Mitra MK, Schenk J (2020) The effect of alkali on the reaction kinetics and strength of blast furnace coke. Fuel 268:117388

Gao X, Du XS, Cui LW, Fu YC, Luo ZY, Cen KF (2010) A Ce–Cu–Ti oxide catalyst for the selective catalytic reduction of NO with NH3. Catal Commun 12(4):255–258

George A, Shen B, Kang D, Yang J, Luo J (2020) Emission control strategies of hazardous trace elements from coal-fired power plants in China. J Environ Sci 93:66–90

Guo X, Qiu Z, Mao J, Zhou R (2018) Doping effect of transition metals (Zr, Mn, Ti and Ni) on well-shaped CuO/CeO2 (rods): nano/micro structure and catalytic performance for selective oxidation of CO in excess H2. Phys Chem Chem Phys 20(40):25983–25994

He C, Shen B, Chi G, Li F (2016) Elemental mercury removal by CeO2/TiO2-PILCs under simulated coal-fired flue gas. Chem Eng J 300:1–8

Hills L, Stevenson R (2006) Mercury and lead content in raw materials. PCAR & D Serial No. 2888

Hutson ND, Attwood BC, Scheckel KG (2007) XAS and XPS characterization of mercury binding on brominated activated carbon. Environ Sci Technol 41(5):1747–1752

Jampaiah D, Tur KM, Venkataswamy P, Ippolito SJ, Sabri YM, Tardio J, Reddy BM (2015) Catalytic oxidation and adsorption of elemental mercury over nanostructured CeO2-MnOx catalyst. RSC Adv 5(38):30331–30341

Li H, Lu G, Qiao D, Wang Y, Guo Y, Guo Y (2011a) Catalytic methane combustion over Co3O4/CeO2 composite oxides prepared by modified citrate sol-gel method. Catal Lett 141:452–458

Li K, Wang H, Wei Y, Yan D (2011b) Partial oxidation of methane to syngas with air by lattice oxygen transfer over ZrO2-modified Ce-Fe mixed oxides. Chem Eng J 173(2):574–582

Li F, Xie J, Fang D, He F, Qi K, Gong P (2017) Mechanistic study of Ce-modified MnOx/TiO2 catalysts with high NH3-SCR performance and SO2 resistance at low temperatures. Res Chem Intermed 43(10):5413–5432

Li Y, Dang L, Yang H, Li J, Hu H (2020) Removal of elemental mercury in flue gas by Cu-Fe modified magnetosphere from coal combustion fly ash. Fuel 271:117668

Liu F, He H (2010) Structure-activity relationship of iron titanate catalysts in the selective catalytic reduction of NOx with NH3. J Phys Chem C 114(40):16929–16936

Liu T, Xue L, Guo X, Liu J, Huang Y, Zheng C (2016) Mechanisms of elemental mercury transformation on α-Fe2O3 (001) surface from experimental and theoretical study: influences of HCl, O2, and SO2. Environ Sci Technol 50(24):13585–13591

Liu K, Wu Q, Wang L, Wang S, Liu T, Ding D, Hao J (2019) Measure-specific effectiveness of air pollution control on China’s atmospheric mercury concentration and deposition during 2013–2017. Environ Sci Technol 53(15):8938–8946

Liu J, Shi X, Liu H, Dong L, Li B (2020) Study on the performance of magnetic Co3O4/γ-Fe2O3 catalyst in NO+CO reaction. Appl Surf Sci 533:147498

Ma J, Li C, Zhao L, Zhang J, Song J, Zeng G, Xie Y (2015) Study on removal of elemental mercury from simulated flue gas over activated coke treated by acid. Appl Surf Sci 329:292–300

Ma Y, Zhang D, Sun H, Wu J, Liang P, Zhang H (2018) Fe-Ce mixed oxides supported on carbon nanotubes for simultaneous removal of NO and Hg0 in flue gas. Ind Eng Chem Res 57(9):3187–3194

Schafer S, Hoenig V (2001) Operational factors affecting the mercury emissions from rotary kilns in the cement industry. ZKG INT 54(11):591–601

Shang D, Qin Z, Wei C (2015) Influence of the preparation method on the catalytic activity of Co/Zr1-xCexO2 for NO oxidation. J Mol Catal a: Chem 399:18–24

Sood S, Umar A, Mehta SK, Kansal SK (2015) Highly effective Fe-doped TiO2 nanoparticles photocatalysts for visible-light driven photocatalytic degradation of toxic organic compounds. J Colloid Interface Sci 450:213–223

Tomova D, Iliev V, Eliyas A, Rakovsky S (2015) Promoting the oxidative removal rate of oxalic acid on gold-doped CeO2/TiO2 photocatalysts under UV and visible light irradiation. Sep Purif Technol 156:715–723

United Nations Environment Programme, Global mercury assessment 2019. UN Environment Programme Chemicals and Health Branch Geneva: Switzerland: 2019

Wan Q, Duan L, Li J, Chen L, He K, Hao J (2011) Deactivation performance and mechanism of alkali (earth) metals on V2O5-WO3/TiO2 catalyst for oxidation of gaseous elemental mercury in simulated coal-fired flue gas. Catal Today 175(1):189–195

Wang B, Li J, Ding N, Mei D, Zhao H, Zheng C (2017) Chemical looping combustion of a typical lignite with a CaSO4-CuO mixed oxygen carrier. Energy Fuels 31(12):13942–13954

Wei L, Cui S, Guo H, Ma X, Wan Y, Yu S (2019) The mechanism of the deactivation of MnOx/TiO2 catalyst for low-temperature SCR of NO. Appl Surf Sci 483:391–398

Xu J, Harmer J, Li G, Chapman T, Collier P, Longworth S, Tsang S (2010) Size dependent oxygen buffering capacity of ceria nanocrystals. Chem Commun 46(11):1887–1889

Yang S, Yan N, Guo Y, Wu D, He H, Qu Z, Jia J (2011) Gaseous elemental mercury capture from flue gas using magnetic nanosized (Fe3-xMnx)1-δO4. Environ Sci Technol 45(4):1540–1546

Yang W, Liu Y, Wang Q, Pan J (2017a) Removal of elemental mercury from flue gas using wheat straw chars modified by Mn-Ce mixed oxides with ultrasonic-assisted impregnation. Chem Eng J 326:169–181

Yang Y, Liu J, Zhang B, Zhao Y, Chen X, Shen F (2017b) Experimental and theoretical studies of mercury oxidation over CeO2-WO3/TiO2 catalysts in coal-fired flue gas. Chem Eng J 317:758–765

Yang S, Liu Z, Yan X, Liu C, Zhang Z, Liu H, Chai L (2019) Catalytic oxidation of elemental mercury in coal-combustion flue gas over the CuAlO2 catalyst. Energy Fuels 33(11):11380–11388

Zhang T, Hing P, Huang H, Kilner J (2001) Densification, microstructure and grain growth in the CeO2-Fe2O3 system(0≤Fe/Ce≤20%). J Eur Ceram Soc 21(12):2221–2228

Zhang N, Li X, Ye H, Chen S, Ju H, Liu D, Xiong Y (2016) Oxide defect engineering enables to couple solar energy into oxygen activation. J Am Chem Soc 138(28):8928–8935

Zhang H, Zhao X, Wang S, Zeng S, Su H (2018a) Change of Cu+ species and synergistic effect of copper and cerium during reduction-oxidation treatment for preferential CO oxidation. Appl Surf Sci 441:754–763

Zhang X, Dong Y, Cui L, An D, Feng Y (2018b) Removal of elemental mercury from coal pyrolysis gas using Fe-Ce oxides supported on lignite semi-coke modified by the hydrothermal impregnation method. Energy Fuels 32(12):12861–12870

Zhang H, Wang T, Zhang Y, Wang J, Sun B, Pan WP (2020a) A review on adsorbent/catalyst application for mercury removal in flue gas: effect of sulphur oxides (SO2, SO3). J Clean Prod 276:124220

Zhang L, Yang S, Lai Y, Liu H, Fan Y, Liu C, Chai L (2020b) In-situ synthesis of monodispersed CuxO heterostructure on porous carbon monolith for exceptional removal of gaseous Hg0. Appl Catal B 265:118556

Zhang X, Han X, Wei Y, Wang X, Zhang N, Bao J, He G (2022) Single-atom Co-NC catalyst for efficient Hg0 oxidation at low temperature. Chem Eng J 428:132660

Zhao H, Yang G, Gao X, Pang C, Kingman S, Lester E, Wu T (2016a) Hg0-temperature-programmed surface reaction and its application on the investigation of metal oxides for Hg0 capture. Fuel 181:1089–1094

Zhao L, Li C, Li S, Wang Y, Zhang J, Wang T, Zeng G (2016b) Simultaneous removal of elemental mercury and NO in simulated flue gas over V2O5/ZrO2-CeO2 catalyst. Appl Catal B 198:420–430

Zhao H, Ezeh CI, Yin S, Xie Z, Pang CH, Zheng C, Wu T (2020) MoO3-adjusted δ-MnO2 nanosheet for catalytic oxidation of Hg0 to Hg2+. Appl Catal B 263:117829

Zhou J, Hou W, Qi P, Gao X, Luo Z, Cen K (2013) CeO2-TiO2 sorbents for the removal of elemental mercury from syngas. Environ Sci Technol 47(17):10056–10062

Zhou M, Xu Y, Luo G, Zhang Q, Du L, Li Z (2022) Removal of elemental mercury from coal combustion flue gas using bentonite modified with Ce-Fe binary oxides. Appl Surf Sci 590:153090

Zhu H, Song X, Han X, Zhang X, Bao J, Zhang N, He G (2020) Co3O4 nanosheets preferentially growing (220) facet with a large amount of surface chemisorbed oxygen for efficient oxidation of elemental mercury from flue gas. Environ Sci Technol 54(14):8601–8611

Funding

Financial supports for this project provided by the Science and Technology Department of Sichuan Province (no. 2022JDRC0101), National Natural Science Foundation of China (no. 21676032), Chengdu University of Information Technology (no. KYTZ202014), Education Department of Sichuan Province (no. 14TD0020), Chengdu Science and Technology Bureau (nos. 2016-GH02-00032-HZ and 2015-HM01-00127-SF), and Chengdu University of Information Technology (no. J201513) are greatly acknowledged.

Author information

Authors and Affiliations

Contributions

Yiting Yang: investigation and writing; Junyuan Guo: writing and editing; Ziyu Zhao and Jie Yang: editing; Jing Cao and Qiang Zhang: investigation; Shengyu Liu: supervision.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: George Z. Kyzas

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Y., Guo, J., Zhao, Z. et al. Efficient removal of Hg0 from cement kiln flue gas using CexFeyOz composite catalyst. Environ Sci Pollut Res 30, 79821–79834 (2023). https://doi.org/10.1007/s11356-023-27781-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-27781-w