Abstract

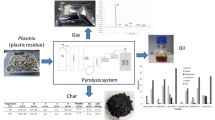

With ever-increasing plastic waste, a robust and sustainable methodology to valorize the waste and tweak, the composition of the value added product is the need of the hour. The present study describes the effect of different heterogeneous catalyst systems on the yield, composition and nature of the pyrolysis oil produced from various waste polyolefins like high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and polypropylene (PP). The waste polyolefins were subjected to thermal as well as catalytic pyrolysis. Liquid, gas, and solid products were obtained during the pyrolysis. Various catalysts such as activated alumina (AAL), ZSM-5, FCC catalyst, and halloysite clay (HNT) were used. Usage of catalysts has reduced the temperature of the pyrolysis reaction from 470 to 450 °C with better liquid product yield. PP waste generated higher liquid yield compared to LLDPE and HDPE waste. The highest liquid yield of 70.0% was achieved with PP waste using AAL catalyst at 450 °C. The sulfur and chloride content was found to be < 10 and < 20 ppm respectively in all the pyrolysis liquid. Pyrolysis liquid products were analyzed using gas chromatography (GC), nuclear magnetic resonance (NMR) spectroscopy, Fourier-transform infrared (FTIR) spectroscopy, X-ray fluorescence (XRF) spectroscopy, and gas chromatography coupled with mass spectrophotometry (GC–MS). The obtained liquid products consist of paraffin, naphthene, olefin and aromatic components. Catalyst regeneration experiments with AAL showed that the product distribution profile remains the same up to three cycles of regeneration.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Achilias DS, Roupakias C, Megalokonomos P, Lappas A, Antonakou EV (2007) Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J Hazard Mater 149:536–542. https://doi.org/10.1016/j.jhazmat.2007.06.076

Aisien ET, Otuya IC, Aisien FA (2021) Thermal and catalytic pyrolysis of waste polypropylene plastic using spent FCC catalyst. Environ Technol Innov 22:101455. https://doi.org/10.1016/j.eti.2021.101455

Almeida D, de Fátima Marques M (2016) Thermal and catalytic pyrolysis of plastic waste. Polímeros 26:44–51. https://doi.org/10.1590/0104-1428.2100

Al-Salem SM, Antelava A, Constantinou A, Manos G, Dutta A (2017) A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J Environ Manag 197:177–198. https://doi.org/10.1016/j.jenvman.2017.03.084

Bineesh KV, Kim SY, Jermy BR, Park DW (2009) Synthesis, characterization and catalytic performance of vanadia-doped delaminated zirconia-pillared montmorillonite clay for the selective catalytic oxidation of hydrogen sulfide. J Mol Catal A Chem 308:150–158. https://doi.org/10.1016/j.molcata.2009.04.002

Brydson JA (1999) Plast Mater, 7th edn, Chapter 1, The historical development of plastic materials. Butterworth-Heinemann, Copyright © Elsevier Ltd.

Butler E, Devlin G, McDonnell K (2011) Waste polyolefins to liquid fuels via pyrolysis: Review of commercial state-of-the-art and recent laboratory research. Waste Biomass Valor 2:227–255. https://doi.org/10.1007/s12649-011-9067-5

Chaianansutcharit S, Katsutath R, Chaisuwan A, Bhaskar T, Nigo A, Muto A, Sakata Y (2007) Catalytic degradation of polyolefins over hexagonal mesoporous silica: Effect of aluminum addition. J Anal Appl Pyrolysis 80:360–368. https://doi.org/10.1016/j.jaap.2007.04.009

Charitopoulou MA, Kalogiannis KG, Lappas AA, Achilias AA (2021) Novel trends in the thermo-chemical recycling of plastics from WEEE containing brominated flame retardants. Environ Sci Pollut Res 28:59190–59213. https://doi.org/10.1007/s11356-020-09932-5

Chunfei W, Williams PT (2010) Pyrolysis–gasification of plastics, mixed plastics and real-world plastic waste with and without Ni–Mg–Al catalyst. Fuel 89:3022–3032. https://doi.org/10.1016/j.fuel.2010.05.032

Cho MH, Jung SH, Kim JS (2010) Pyrolysis of mixed plastic wastes for the recovery of benzene, toluene, and xylene (BTX) aromatics in a fluidized bed and chlorine removal by applying various additives. Energy Fuels 24:1389–1395. https://doi.org/10.1021/ef901127v

Costa CS, Muñoz M, Ribeiro MR, Silva JM (2021) H-USY and H-ZSM-5 zeolites as catalysts for HDPE conversion under a hydrogen reductive atmosphere. Sustain Energy Fuels 5:1134–1147. https://doi.org/10.1039/D0SE01584A

Cullis CF, Hirschler MM (1981) The combustion of organic polymers. Oxford University Press. https://doi.org/10.1002/pol.1982.130201115

Daligaux V, Richard R, Manero MH (2021) Deactivation and regeneration of zeolite catalysts used in pyrolysis of plastic wastes—a process and analytical review. Catalysts 11:770. https://doi.org/10.3390/catal11070770

Das P, Tiwari P (2018) Valorization of packaging plastic waste by slow pyrolysis. Resour Conserv Recy 128:69–77. https://doi.org/10.1016/j.resconrec.2017.09.025

Donaj PJ, Kaminsky W, Buzeto F, Yang W (2012) Pyrolysis of polyolefins for increasing the yield of monomers’ recovery. Waste Manag 32:840–846. https://doi.org/10.1016/j.wasman.2011.10.009

Dubdub I, Al-Yaari M (2020) Pyrolysis of mixed plastic waste: I. Kinetic study. Materials 13:4912. https://doi.org/10.3390/ma13214912

Dwivedi P, Mishra PK, Mondal MK, Srivastava N (2019) Non-biodegradable polymeric waste pyrolysis for energy recovery. Heliyon 5:e02198. https://doi.org/10.1016/j.heliyon.2019.e02198

Gao F (2010) Pyrolysis of waste plastics into fuels. Ph.D.Thesis, Univ Canterbury New Zealand. https://doi.org/10.26021/3251

Guisnet M, Costa L, Ribeiro FR (2009) Prevention of zeolite deactivation by coking. J Mol Catal A Chem 305:69–83. https://doi.org/10.1016/j.molcata.2008.11.012

Hakeem IG, Aberuagba F, Musa U (2018) Catalytic pyrolysis of waste polypropylene using Ahoko kaolin from Nigeria. Appl Petrochem Res 8:203–210. https://doi.org/10.1007/s13203-018-0207-8

Hwang EY, Kim JR, Choi JK, Woo HC, Park DW (2002) Performance of acid treated natural zeolites in catalytic degradation of polypropylene. J Anal Appl Pyrolysis 62:351–364. https://doi.org/10.1016/S0165-2370(01)00134-6

Jadhao SB, Seethamraju S (2020) Pyrolysis study of mixed plastics waste. IOP Conf Ser Mater Sci Eng 736:042036. https://doi.org/10.1088/1757-899X/736/4/042036

Jahnavi N, Kanmani K, Kumar PS, Varjani S (2021) Conversion of waste plastics into low emissive hydrocarbon fuel using catalyst produced from biowaste. Environ Sci Pollut Res 28:63638–63645. https://doi.org/10.1007/s11356-020-11398-4

Jing X, Yan G, Zhao Y, Wen H, Xu Z (2014) Study on mild cracking of polyolefins to liquid hydrocarbons in a closed batch reactor for subsequent olefin recovery. Polym Degrad Stab 109:79–91. https://doi.org/10.1016/j.polymdegradstab.2014.07.003

Kaminsky W, Schlesselmann B, Simon CM (1996) Thermal degradation of mixed plastic waste to aromatics and gas. Polym Degrad Stab 53:189–197. https://doi.org/10.1016/0141-3910(96)00087-0

Kumar S, Panda AK, Singh RK (2011) A review on tertiary recycling of high-density polyethylene to fuel. Resour Conserv Recy 55:893–910. https://doi.org/10.1016/j.resconrec.2011.05.005

Larrain M, Passel SV, Thomassen G, Kresovic U, Alderweireldt N, Moerman E, Billen P (2020) Economic performance of pyrolysis of mixed plastic waste: open-loop versus closed-loop recycling. J Clean Prod 270:122442. https://doi.org/10.1016/j.jclepro.2020.122442

Lee KH (2009) Thermal and catalytic degradation of pyrolytic oil from pyrolysis of municipal plastic wastes. J Anal Appl Pyrolysis 85:372–379. https://doi.org/10.1016/j.jaap.2008.11.032

Lee KH, Jeon SG, Kim KH, Noh NS, Shin DH, Park J, Seo Y, Yee JJ, Kim GT (2003) Thermal and catalytic degradation of waste high-density polyethylene (HDPE) using spent FCC catalyst. Korean J Chem Eng 20:693–697

Lee KH, Noh NS, Shin DH, Seo Y (2002) Comparison of plastic types for catalytic degradation of waste plastics into liquid product with spent FCC catalyst. Polym Degrad Stab 78:539–544. https://doi.org/10.1016/S0141-3910(02)00227-6

Lin YH, Yang MH, Yeh TF, Ger MD (2004) Catalytic degradation of high density polyethylene over mesoporous and microporous catalysts in a fluidised-bed reactor. Polym Deg Stabil 86:121–128. https://doi.org/10.1016/j.polymdegradstab.2004.02.015

Lopez G, Artetxe M, Amutio M, Bilbao J, Olazar M (2017) Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals. A review. Renew Sustain Energy Rev 73:346–368. https://doi.org/10.1016/j.rser.2017.01.142

Lopez A, Marco ID, Caballero BM, Laresgoiti MF, Adrados A, Aranzabal A (2011a) Catalytic pyrolysis of plastic wastes with two different types of catalysts: ZSM-5 zeolite and Red Mud. Appl Catal B Environ 104:211–219. https://doi.org/10.1016/j.apcatb.2011.03.030

López A, Marco ID, Caballero BM, Laresgoiti MF, Adrados A (2011b) Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem Eng J 173:62–71. https://doi.org/10.1016/j.cej.2011.07.037

Lopez A, Marco ID, Caballero BM, Laresgoiti MF, Adrados A (2012) Catalytic stepwise pyrolysis of packaging plastic waste. J Anal Appl Pyrolysis 96:54–62. https://doi.org/10.1016/j.jaap.2012.03.004

Ma X, Park C, Moultrie J (2020) Factors for eliminating plastic in packaging: the European FMCG experts’ view. J Clean Prod 256:120492. https://doi.org/10.1016/j.jclepro.2020.120492

Manos G, Garforth A, Dwyer J (2000) Catalytic degradation of high-density polyethylene over different zeolitic structures. Ind Eng Chem Res 39:1198–1202. https://doi.org/10.1021/ie990512q

Manos G, Yusof IY, Papayannakos N, Gangas NH (2001) Catalytic cracking of polyethylene over clay catalysts. Comparison with an ultrastable Y zeolite. Ind Eng Chem Res 40:2220–2225. https://doi.org/10.1021/ie001048o

Miandad R, Barakat MA, Aburiazaiza AS, Rehan M, Nizami AS (2016) Catalytic pyrolysis of plastic waste: a review. Process Saf Environ Prot 102:822–838. https://doi.org/10.1016/j.psep.2016.06.022

Miskolczi N, Angyal A, Bartha L, Valkai I (2009) Fuels by pyrolysis of waste plastics from agricultural and packaging sectors in a pilot scale reactor. Fuel Process Technol 90:1032–1040. https://doi.org/10.1016/j.fuproc.2009.04.019

Miskolczi N, Bartha L, Deáka G, Jóverb B, Kalló D (2004) Thermal and thermo-catalytic degradation of high-density polyethylene waste. J Anal Appl Pyrolysis 72:235–242. https://doi.org/10.1016/j.jaap.2004.07.002

Olazar M, Lopez G, Amutio M, Elordi G, Aguado R, Bilbao J (2009) Influence of FCC catalyst steaming on HDPE pyrolysis product distribution. J Anal Appl Pyrolysis 85:359–365. https://doi.org/10.1016/j.jaap.2008.10.016

Ofoma I (2006) Catalytic pyrolysis of polyolefins. Ph.D.Thesis, Georgia Insti Tech United States

Ohkita H, Nishiyama R, Tochihara Y, Mizushima T, Kakuta N, Morioka Y, Ueno A, Namiki Y, Tanifuji HKS, Sunazuka H, Nakayam R, Kuroyanagi T (1993) Acid properties of silica-alumina catalysts and catalytic degradation of polyethylene. Ind Eng Chem 32:3112–3116. https://doi.org/10.1021/ie00024a02

Palos R, Gutierrez A, Vela FJ, Mana JA, Asueta IHA, Arnaiz S, Arandes JM, Bilbao J (2019) Assessing the potential of the recycled plastic slow pyrolysis for the production of streams attractive for refineries. J Anal Appl Pyrolysis 142:104668. https://doi.org/10.1016/j.jaap.2019.104668

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel: a suitable method for plastic waste management and manufacture of value added products - a world prospective. Renew Sustain Energy Rev 14:233–248. https://doi.org/10.1016/j.rser.2009.07.005

Park DW, Hwanga EY, Kim JR, Choi JK, Kim YA, Woo HC (1999) Catalytic degradation of polyethylene over solid acid catalysts. Polym Degrad Stab 65:193–198. https://doi.org/10.1016/S0141-3910(99)00004-X

Park SS, Seo DK, Lee SH, Yu TU, Hwang J (2012) Study on pyrolysis characteristics of refuse plastic fuel using lab-scale tube furnace and thermogravimetric analysis reactor. J Anal Appl Pyrolysis 97:29–38. https://doi.org/10.1016/j.jaap.2012.06.009

Patni N, Shah P, Agarwal S, Singhal P (2013) Alternate strategies for conversion of waste plastic to fuels. Renew Energy. https://doi.org/10.1155/2013/902053

Pinto F, Costa P, Gulyurtlu I, Cabrita I (1999) Pyrolysis of plastic wastes. 1. Effect of plastic waste composition on product yield. J Anal Appl Pyrolysis 51:39–55. https://doi.org/10.1016/S0165-2370(99)00007-8

Rajamohan S, Marshal JJ, Suresh S (2021) Derivation of synthetic fuel from waste plastic: investigation of engine operating characteristics on DI diesel engine. Environ Sci Pollut Res 28:11976–11987. https://doi.org/10.1007/s11356-020-08625-3

Ratnasari DK, Nahil MA, Williams PT (2017) Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils. J Anal Appl Pyrolysis 124:631–637. https://doi.org/10.1016/j.jaap.2016.12.027

Rehan M, Miandad R, Barakat MA, Ismail IMI, Almeelbi T, Gardy J, Hassanpour A, Khan MZ, Demirbas A, Nizami AS (2017) Effect of zeolite catalysts on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:162–175. https://doi.org/10.1016/j.ibiod.2016.11.015

Rowatt RJ (1993) The plastic waste problem. ChemTech 23:56–60

Saha D, Sinha A, Roy B (2021) Critical insights into the effects of plastic pyrolysis oil on emission and performance characteristics of CI engine. Environ Sci Pollut Res 28:44598–44621. https://doi.org/10.1007/s11356-021-14919-x

Sarker M, Kabir A, Rashid MM, Molla M, Mohammad ASMD (2011) Waste polyethylene terephthalate (PETE-1) Conversion into liquid Fuel. J Fundam Renew Energy Appl 1:1–5. https://doi.org/10.4303/jfrea/R101202

Serrano DP, Aguado J, Escola JM, Rodriguez JM, Peral A (2010) Catalytic properties in polyolefin cracking of hierarchical nanocrystalline HZSM-5 samples prepared according to different strategies. J Catal 276:152–160. https://doi.org/10.1016/j.jcat.2010.09.008

Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK (2016) A review on pyrolysis of plastic wastes. Energy Convers Manag 115:308–326. https://doi.org/10.1016/j.enconman.2016.02.037

Siddiqui MN, Redhwi HH (2009) Pyrolysis of mixed plastics for the recovery of useful products. Fuel Process Technol 90:545–552. https://doi.org/10.1016/j.fuproc.2009.01.003

Singh B, Sharma N (2008) Mechanistic implications of plastic degradation. Polym Degrad Stab 93:561–584. https://doi.org/10.1016/j.polymdegradstab.2007.11.008

Soni VK, Singh G, Vijayan BK, Chopra A, Kapur GS, Ramakumar SSV (2021) Thermochemical recycling of waste plastics by pyrolysis: a review. Energy Fuels 35:12763–12808. https://doi.org/10.1021/acs.energyfuels.1c01292

Tekin K, Akalın MK, Kadı Ç, Karagöz S (2012) Catalytic degradation of waste polypropylene by pyrolysis. J Energy Inst 85:150–155. https://doi.org/10.1179/1743967112Z.00000000029

Uemichi Y, Hattori M, Itoh T, Nakamura J, Sugioka M (1998) Deactivation behaviors of zeolite and silica-alumina catalysts in the degradation of polyethylene. Ind Eng Chem Res 37:867–872. https://doi.org/10.1021/ie970605c

Vasile C, Pakdel H, Mihai B, Onu P, Darie H, Ciocalteu S (2001) Thermal and catalytic decomposition of mixed plastics. J Anal Appl Pyrolysis 57:287–303. https://doi.org/10.1016/S0165-2370(00)00151-0

Williams PT, Williams EA (1999) Fluidised bed pyrolysis of low density polyethylene to produce petrochemical feedstock. J Anal Appl Pyrolysis 51:107–126. https://doi.org/10.1016/S0165-2370(99)00011-X

Author information

Authors and Affiliations

Contributions

Bineesh Vijayan Kanattukara conceptualized the work, conducted experiments, and drafted the original manuscript. Gurmeet Singh checked and reviewed the manuscript. Preetom Sarkar assisted in conducting the experiments, interpretation of the data, and drafting of manuscript. Anju Chopra reviewed the manuscript. Dheer Singh conducted the gas chromatography experiments. Sujit Mondal conducted the NMR experiments. Gurpreet Singh Kapur and Sankara Sri Venkata Ramakumar reviewed the manuscript. All the authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanattukara, B.V., Singh, G., Sarkar, P. et al. Catalyst-mediated pyrolysis of waste plastics: tuning yield, composition, and nature of pyrolysis oil. Environ Sci Pollut Res 30, 64994–65010 (2023). https://doi.org/10.1007/s11356-023-27044-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-27044-8