Abstract

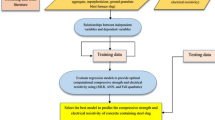

Concrete is a composite material widely used in construction. Waste slag smelting (pyrometallurgical) (steel slag (SS)) is a molten liquid melt of silicates and oxides created as a by-product of steel production. It is a complex solution of silicates and oxides. Steel slag recovery conserves natural resources and frees up landfill space. Steel slag has been used in concrete to replace fine and coarse particles (gravel). Three hundred thirty-eight data points were collected, analyzed, and modeled. It was determined which factors influenced the compressive strength of concrete with steel slag replacement in the modeling phase. Water/cement ratio was 0.3–0.872, steel slag content 0–1196 kg/m3, fine aggregate content 175.5–1285 kg/m3, and coarse aggregate content (natural aggregate) 0–1253.75 kg/m3. In addition, 134 data were collected regarding the electrical conductivity of concrete to analyze and model the effect of SS on electrical conductivity. The correlation between compressive strength and electrical conductivity was also observed. This research used a linear regression (LR) model, a nonlinear regression (NLR) model, an artificial neural network (ANN), a full quadratic model (FQ), and an M5P tree model to anticipate the compressive strength of normal strength concrete with steel slag aggregate substitution. For predicting the electrical conductivity, the ANN model was performed. The compressive strength of the steel slag was raised based on data from the literature. Statistical techniques like the dispersion index and Taylor diagram showed that the ANN model with the lowest RMSE predicted compressive strength better than the other models.

Similar content being viewed by others

Data availability

The data supporting the conclusions of this article are included in the article.

References

Adegoloye G, Beaucour A-L, Ortola S, Noumowe A (2016) Mineralogical composition of EAF slag and stabilised AOD slag aggregates and dimensional stability of slag aggregate concretes. Constr Build Mater 115:171–178

Ahmad A, Farooq F, Niewiadomski P, Ostrowski K, Akbar A, Aslam F, Alyousef R (2021) Prediction of compressive strength of fly ash based concrete using individual and ensemble algorithm. Materials 14:794

Ahmad SI, Rahman M (2018) Mechanical and durability properties of induction-furnace-slag-incorporated recycled aggregate concrete. Adv Civ Eng 2018

Ahmed HU, Mohammed AA, Rafiq S, Mohammed AS, Mosavi A, Sor NH, Qaidi S (2021) Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 13:13502

Ahmed HU, Abdalla AA, Mohammed AS, Mohammed AA, Mosavi A (2022) Statistical Methods for Modeling the Compressive Strength of Geopolymer Mortar. Materials 15:1868

Al-Shamiri AK, Yuan T-F, Kim JH (2020) Non-tuned machine learning approach for predicting the compressive strength of high-performance concrete. Materials 13:1023

Al Qadi AN, Mustapha KNB, Al-Mattarneh H, AL-Kadi QN (2009) Statistical models for hardened properties of self-compacting concrete. Am J Eng Appl Sci 2(4)

Ali B, Kurda R, Herki B, Alyousef R, Mustafa R, Mohammed A, Raza A, Ahmed H, Fayyaz Ul-Haq M (2020) Effect of varying steel fiber content on strength and permeability characteristics of high strength concrete with micro silica. Materials 13:5739

Armaghani DJ, Mohamad ET, Narayanasamy MS, Narita N, Yagiz S (2017) Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn Undergr Space Technol 63:29–43

Armaghani DJ, Asteris PG (2021) A comparative study of ANN and ANFIS models for the prediction of cement-based mortar materials compressive strength. Neural Comput Appl 33:4501–4532

Armaghani DJ, Harandizadeh H, Momeni E, Maizir H, Zhou J (2022) An optimized system of GMDH-ANFIS predictive model by ICA for estimating pile bearing capacity. Artif Intell Rev 55(3):2313–2350

Asi IM, Qasrawi HY, Shalabi FI (2007) Use of steel slag aggregate in asphalt concrete mixes. Can J Civ Eng 34:902–911

Aslam F, Farooq F, Amin MN, Khan K, Waheed A, Akbar A, Alabdulijabbar H (2020) Applications of gene expression programming for estimating compressive strength of high-strength concrete. Adv Civ Eng 2020

Badiee H, Maghsoudipour A, Raissi Dehkordi B (2008) Use of Iranian steel slag for production of ceramic floor tiles. Adv Appl Ceram 107:111–115

Ban CC, Jasme N (2018) Preliminary Study on Properties of Supersulfated Flowable Mortars Containing Electric Arc Furnace Slag as Fine Aggregate. Int J Eng Technol 7:371–374

Barzinjy AA, Abdul DA, Hussain FH, Hamad SM (2020) Green synthesis of the magnetite (Fe3O4) nanoparticle using Rhus coriaria extract: a reusable catalyst for efficient synthesis of some new 2-naphthol bis-Betti bases. Inorg Nano-Metal Chem 50:620–629

Barzinjy AA, Azeez HH (2020) Green synthesis and characterization of zinc oxide nanoparticles using Eucalyptus globulus Labill. leaf extract and zinc nitrate hexahydrate salt. SN Appl Sci 2:991

Baweja D, Roper H, Sirvivatnanon V (1996) Corrosion of steel in marine concrete: Long-term half-cell potential and resistivity data. Special Publication 163:89–110

Beshr H, Almusallam A, Maslehuddin M (2003) Effect of coarse aggregate quality on the mechanical properties of high strength concrete. Constr Build Mater 17:97–103

Bing L, Biao T, Zhen M, Hanchi C, Hongbo L (2019) Physical and chemical properties of steel slag and utilization technology of steel slag at home and abroad, IOP Conference Series: Earth and Environmental Science. IOP Publishing, pp. 032012

Bouafia A, Laouini SE, Khelef A, Tedjani ML, Guemari F (2021) Effect of Ferric Chloride Concentration on the Type of Magnetite (Fe3O4) Nanoparticles Biosynthesized by Aqueous Leaves Extract of Artemisia and Assessment of Their Antioxidant Activities. J Cluster Sci 32:1033–1041

Chavepeyr G, JM L (1979) Etude de la composition minéralogique des scories LD

Chen H, Asteris PG, Jahed Armaghani D, Gordan B, Pham BT (2019) Assessing dynamic conditions of the retaining wall: developing two hybrid intelligent models. Appl Sci 9:1042

Chi L, Wang Z, Lu S, Zhao D, Yao Y (2019) Development of mathematical models for predicting the compressive strength and hydration process using the EIS impedance of cementitious materials. Constr Build Mater 208:659–668

Chopra P, Sharma RK, Kumar M (2015) Artificial neural networks for the prediction of compressive strength of concrete. Int J Appl Sci Eng 13:187–204

Chung KL, Wang L, Ghannam M, Guan M, Luo J (2021) Prediction of concrete compressive strength based on early-age effective conductivity measurement. J Build Eng 35:101998

Cornacchia G, Agnelli S, Gelfi M, Ramorino G, Roberti R (2015) Reuse of EAF slag as reinforcing filler for polypropylene matrix composites. Jom 67:1370–1378

Crainic N, Marques AT (2002) Nanocomposites: a state-of-the-art review. Key Eng Mater 230:656

Dahish HA, Bakri M, Alfawzan MS (2021) Predicting the strength of cement mortars containing natural pozzolan and silica fume using multivariate regression analysis. Int J 20:68–76

de Grazia MT, Deda H, Sanchez LF (2021) The influence of the binder type & aggregate nature on the electrical resistivity of conventional concrete. J Build Eng 43:102540

Dhumal J, Bandgar S, Zipare K, Shahane G (2015) Fe3O4 ferrofluid nanoparticles: synthesis and rheological behavior. Int J Mater Chem Phys 1:141–145

Dong B, Zhang J, Wang Y, Fang G, Liu Y, Xing F (2016) Evolutionary trace for early hydration of cement paste using electrical resistivity method. Constr Build Mater 119:16–20

Farrand B, Emery J (1995) Recent improvements in quality of steel slag aggregate. Transp Res Rec 1468:137–141

Ferreira RM, Jalali S (2010) NDT measurements for the prediction of 28-day compressive strength. NDT and E Int 43:55–61

FM Zain M, M Abd S (2009) Multiple regression model for compressive strength prediction of high performance concrete. J Appl Sci 9:155-160

Fuente-Alonso JA, Ortega-López V, Skaf M, Aragón Á, San-Jose JT (2017) Performance of fiber-reinforced EAF slag concrete for use in pavements. Constr Build Mater 149:629–638

Furlani E, Tonello G, Maschio S (2010) Recycling of steel slag and glass cullet from energy saving lamps by fast firing production of ceramics. Waste Manage 30:1714–1719

García-Cuadrado J, Santamaría-Vicario I, Rodríguez A, Calderón V, Gutiérrez-González S (2018) Lime-cement mortars designed with steelmaking slags as aggregates and validation study of their properties using mathematical models. Constr Build Mater 188:210–220

Garcia-Guinea J, Correcher V, Recio-Vazquez L, Crespo-Feo E, Gonzalez-Martin R, Tormo L (2010) Influence of accumulation of heaps of steel slag on the environment: determination of heavy metals content in the soils. An Acad Bras Ciênc 82:267–277

García-Macías E, D’Alessandro A, Castro-Triguero R, Pérez-Mira D, Ubertini F (2017) Micromechanics modeling of the uniaxial strain-sensing property of carbon nanotube cement-matrix composites for SHM applications. Compos Struct 163:195–215

Geiseler J (1996) Use of steelworks slag in Europe. Waste Manage 16:59–63

Materials. Committee C-9 on Concrete and Concrete Aggregates (1978) Significance of tests and properties of concrete and concrete-making materials (Vol. 169). ASTM International

Hasanipanah M, Monjezi M, Shahnazar A, Armaghani DJ, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297

Hawreen A, Bogas J (2019) Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr Build Mater 198:70–81

Hekal E, Abo-El-Enein S, El-Korashy S, Megahed G, El-Sayed T (2013) Hydration characteristics of Portland cement–Electric arc furnace slag blends. HBRC Journal 9:118–124

Hong S-H, Yuan T-F, Choi J-S, Yoon Y-S (2020) Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete. Materials (basel) 13:2675

Illston JM, Domone P (2001) Construction materials: their nature and behaviour. CRC Press

Jiang S, Zhou D, Zhang L, Ouyang J, Yu X, Cui X, Han B (2018) Comparison of compressive strength and electrical resistivity of cementitious composites with different nano-and micro-fillers. Arch Civ Mech Eng 18:60–68

Jonczy I, Grzesik B, Stawowiak M, Gerle A (2020) Characteristics of selected physical and mechanical properties as well as chemical composition of aggregates based on: steel slags, porphyry and diabase. Arch Civ Eng 66(4)

Chandra S (2004) Implications of using recycled construction demolition waste as aggregate in concrete. In Sustainable Waste Management and Recycling: Construction Demolition Waste (pp. 104–114). Thomas Telford Publishing

Kalyoncu RS (2001) Slag-iron and steel. US geological survey minerals yearbook, 701–707

Khademi F, Jamal SM (2016) Predicting the 28 days compressive strength of concrete using artificial neural network. I-Manager’s J Civ Eng 6:1–7

Khaloo A, Mobini MH, Hosseini P (2016) Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr Build Mater 113:188–201

Kim H, Han G, Byun T (1999) A study on the characteristics of LD slag aggregates. Journal of RIST 13:285–289

Kohavi R (1995) A study of cross-validation and bootstrap for accuracy estimation and model selection. In Ijcai 14(2):1137–1145

Koopialipoor M, Asteris PG, Mohammed AS, Alexakis DE, Mamou A, Armaghani DJ (2022) Introducing stacking machine learning approaches for the prediction of rock deformation. Transp Geotech 100756

Kurda R, Salih A, Shakor P, Saleh P, Alyousef R, Ahmed H, Aslanif F (2022) Mix design of concrete: Advanced particle packing model by developing and combining multiple frameworks. Constr Build Mater 320:126218

Lam L, Wong Y, Poon C-S (1998) Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cem Concr Res 28:271–283

Lam MN-T, Le D-H, Jaritngam S (2018) Compressive strength and durability properties of roller-compacted concrete pavement containing electric arc furnace slag aggregate and fly ash. Constr Build Mater 191:912–922

Lateef KB, Rezan SA, Nurulakmal MS (2014) Assessment of EAF Steel Slag Solubility by Statistical Design. Adv Mater Res 858:228–235

Li C, Zhou J, Armaghani DJ, Li X (2021) Stability analysis of underground mine hard rock pillars via combination of finite difference methods, neural networks, and Monte Carlo simulation techniques. Underground Space 6:379–395

Lim J, Lee K, Chong TS, Abdullah L, Razak M, Tezara C (2017) Phosphorus removal by electric arc furnace steel slag adsorption, IOP Conference Series: Materials Science and Engineering. IOP Publishing, pp. 012063

Lim JS, Cheah CB, Ramli MB (2019) The setting behavior, mechanical properties and drying shrinkage of ternary blended concrete containing granite quarry dust and processed steel slag aggregate. Constr Build Mater 215:447–461

Lin C-J, Wu N-J (2021) An ANN Model for Predicting the Compressive Strength of Concrete. Appl Sci 11:3798

Lübeck A, Gastaldini A, Barin D, Siqueira H (2012) Compressive strength and electrical properties of concrete with white Portland cement and blast-furnace slag. Cement Concr Compos 34:392–399

MacLeod AJ, Fehervari A, Gates WP, Garcez EO, Aldridge LP, Collins F (2020) Enhancing fresh properties and strength of concrete with a pre-dispersed carbon nanotube liquid admixture. Constr Build Mater 247:118524

Mahdavi M, Ahmad MB, Haron MJ, Namvar F, Nadi B, Rahman MZA, Amin J (2013) Synthesis, surface modification and characterisation of biocompatible magnetic iron oxide nanoparticles for biomedical applications. Molecules 18:7533–7548

Maslehuddin M, Sharif AM, Shameem M, Ibrahim M, Barry M (2003) Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr Build Mater 17:105–112

Meddah MS, Zitouni S, Belâabes S (2010) Effect of content and particle size distribution of coarse aggregate on the compressive strength of concrete. Constr Build Mater 24:505–512

Miah MJ, Patoary M, Hossain M, Paul SC, Babafemi AJ, Panda B (2020) Enhancement of Mechanical Properties and Porosity of Concrete Using Steel Slag Coarse Aggregate. Materials 13:2865

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W (2020) Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J Build Eng, 101851

Mohammed N, Arun D P (2012) Utilization of industrial waste slag as aggregate in concrete applications by adopting Taguchi’s approach for optimization. Open J Civ Eng

Momeni E, Nazir R, Armaghani DJ, Maizir H (2014) Prediction of pile bearing capacity using a hybrid genetic algorithm-based ANN. Measurement 57:122–131

Monosi S, Ruello ML, Sani D (2016) Electric arc furnace slag as natural aggregate replacement in concrete production. Cement Concr Compos 66:66–72

Motevalizadeh S, Sedghi R, Rooholamini H (2020) Fracture properties of asphalt mixtures containing electric arc furnace slag at low and intermediate temperatures. Constr Build Mater 240:117965

Motz H, Geiseler J (2001) Products of steel slags an opportunity to save natural resources. Waste Manage 21:285–293

Naeej M, Bali M, Naeej MR, Amiri JV (2013) Prediction of lateral confinement coefficient in reinforced concrete columns using M5′ machine learning method. KSCE J Civ Eng 17:1714–1719

Neville A (1995) Properties of concrete (Vol. 4): Longman London

Neville AM, Brooks JJ (1987) Concrete technology. Longman Scientific & Technical England

Nili M, Ehsani A, Shabani K (2010) Influence of nano-SiO2 and micro-silica on concrete performance, Proceedings Second International Conference on Sustainable Construction Materials and Technologies, pp. 1–5

Nunes VA, Borges PH (2021) Recent advances in the reuse of steel slags and future perspectives as binder and aggregate for alkali-activated materials. Constr Build Mater 281:122605

Omale SO, Choong TS, Abdullah LC, Siajam SI, Yip MW (2019) Utilization of Malaysia EAF slags for effective application in direct aqueous sequestration of carbon dioxide under ambient temperature. Heliyon 5:e02602

Palod R, Deo S, Ramtekkar G (2020) Effect on mechanical performance, early age shrinkage and electrical resistivity of ternary blended concrete containing blast furnace slag and steel slag. Materials Today: Proceedings 32:917–922

Parsajoo M, Armaghani DJ, Mohammed AS, Khari M, Jahandari S (2021) Tensile strength prediction of rock material using non-destructive tests: A comparative intelligent study. Transp Geotech 31:100652

Piro NS, Mohammed AS, Hamad SM (2021) Multiple Analytical Models to Evaluate the Impact of Carbon Nanotubes on the Electrical Resistivity and Compressive Strength of the Cement Paste. Sustainability 13:12544

Proctor D, Fehling K, Shay E, Wittenborn J, Green J, Avent C, Bigham R, Connolly M, Lee B, Shepker T (2000) Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ Sci Technol 34:1576–1582

Qadir W, Ghafor K, Mohammed A (2019) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civ Eng 2019

Quinlan JR (1992) Learning with continuous classes, 5th Australian joint conference on artificial intelligence. World Scientific, pp. 343–348

Rahimzadeh CY, Salih A, Barzinjy AA (2022) Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages. Sustainability 14:1723

Roslan NH, Ismail M, Khalid NHA, Muhammad B (2020) Properties of concrete containing electric arc furnace steel slag and steel sludge. J Build Eng 28:101060

Salemi N, Behfarnia K (2013) Effect of nano-particles on durability of fiber-reinforced concrete pavement. Constr Build Mater 48:934–941

Saly F, Guo L, Ma R, Gu C, Sun W (2018) Properties of steel slag and stainless steel slag as cement replacement materials: a comparative study. Journal of Wuhan University of Technology-Mater. Sci Ed 33:1444–1451

Santamaría A, Orbe A, Losañez M, Skaf M, Ortega-Lopez V, González JJ (2017) Self-compacting concrete incorporating electric arc-furnace steelmaking slag as aggregate. Mater Des 115:179–193

Sarkar R, Singh N, Das Kumar S (2010) Utilization of steel melting electric arc furnace slag for development of vitreous ceramic tiles. Bull Mater Sci 33:293–298

Sharba AA (2019) The efficiency of steel slag and recycled concrete aggregate on the strength properties of concrete. KSCE J Civ Eng 23:4846–4851

Shariati M, Mafipour MS, Ghahremani B, Azarhomayun F, Ahmadi M, Trung NT, Shariati A (2020) A novel hybrid extreme learning machine–grey wolf optimizer (ELM-GWO) model to predict compressive strength of concrete with partial replacements for cement. Engineering with Computers, 1–23

Shi C (2004) Steel slag—its production, processing, characteristics, and cementitious properties. J Mater Civ Eng 16:230–236

Singh B, Sihag P, Tomar A, SEHGAL A (2019) Estimation of compressive strength of high-strength concrete by random forest and M5P model tree approaches. J Mater Eng Struct «JMES» 6, 583–592

Skaf M, Manso JM, Aragón Á, Fuente-Alonso JA, Ortega-López V (2017) EAF slag in asphalt mixes: A brief review of its possible re-use. Resour Conserv Recycl 120:176–185

Tarawneh SA, Gharaibeh ES, Saraireh FM (2014) Effect of using steel slag aggregate on mechanical properties of concrete. Am J Appl Sci 11:700

Taylor KE (2001) Summarizing multiple aspects of model performance in a single diagram. J Geophys Res.-Atmos 106:7183–7192

Tenza-Abril AJ, Villacampa Y, Solak AM, Baeza-Brotons F (2018) Prediction and sensitivity analysis of compressive strength in segregated lightweight concrete based on artificial neural network using ultrasonic pulse velocity. Constr Build Mater 189:1173–1183

Teo P-T, Anasyida AS, Basu P, Nurulakmal MS (2014) Recycling of Malaysia’s electric arc furnace (EAF) slag waste into heavy-duty green ceramic tile. Waste Manage 34:2697–2708

Ter Teo P, Anasyida AS, Kho CM, Nurulakmal MS (2019) Recycling of Malaysia’s EAF steel slag waste as novel fluxing agent in green ceramic tile production: Sintering mechanism and leaching assessment. J Clean Prod 241:118144

Vesmawala GR, Vaghela AR, Yadav K, Patil Y (2020) Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Materials Today: Proceedings 28:1170–1174

VG Vk, Prem AA (2018) Green synthesis and characterization of iron oxide nanoparticles using Phyllanthus niruri extract. Orient J Chem 34:2583

Vickers NJ (2017) Animal communication: when i’m calling you, will you answer too? Curr Biol 27:R713–R715

Vinotha G, Sundar T, Amuthalakshmi D, Vivek M (2019) Two new molecular preprocessing schemes for machine learning and their evaluation using some DT algorithms, AIP Conference Proceedings. AIP Publishing LLC, pp. 020011

Vipulanandan C, Mohammed A, Ganpatye A (2018) Smart cement performance enhancement with NanoAl2O3 for real time monitoring applications using Vipulanandan models, Offshore technology conference. OnePetro

Wee T, Suryavanshi AK, Tin S (2000) Evaluation of rapid chloride permeability test (RCPT) results for concrete containing mineral admixtures. Mater J 97:221–232

Wei X, Tian K, Xiao L (2010) Prediction of compressive strength of Portland cement paste based on electrical resistivity measurement. Adv Cem Res 22:165–170

Wei X, Xiao L, Li Z (2012) Prediction of standard compressive strength of cement by the electrical resistivity measurement. Constr Build Mater 31:341–346

Xiao L, Wei X (2011) Early age compressive strength of pastes by electrical resistivity method and maturity method. Journal of Wuhan University of Technology-Mater. Sci Ed 26:983–989

Yi H, Xu G, Cheng H, Wang J, Wan Y, Chen H (2012) An overview of utilization of steel slag. Procedia Environ Sci 16:791–801

Yildirim IZ, Prezzi M (2011) Chemical, mineralogical, and morphological properties of steel slag. Adv Civ Eng

Yousif ST, Abdullah SM (2009) Artificial Neural Network Model for Predicting Compressive. Tikrit J Eng Sci (TJES) 16:55–66

Zhang P, Wang L, Wei H, Wang J (2021) A Critical Review on Effect of Nanomaterials on Workability and Mechanical Properties of High-Performance Concrete. Adv Civ Eng

Zhou C, Zhu H, Wang Q, Wang J, Cheng J, Guo Y, Zhou X, Bai R (2017) Adsorption of mercury (II) with an Fe 3 O 4 magnetic polypyrrole–graphene oxide nanocomposite. RSC Adv 7:18466–18479

Acknowledgements

Scientific Research Centre, Soran University, supported this work.

Author information

Authors and Affiliations

Contributions

Nzar, Rawaz, and Ahmed S. Mohammed are collecting data, planning, and writing. Nzar, Samir, and Rawaz, results and analysis. Ahmed and Nzar did the conclusions and editing.

Corresponding author

Ethics declarations

Declarations

We wish to draw the attention of the editor to the following facts, which may be considered potential conflicts of interest and to significant financial contributions to this work. [OR] We wish to confirm that no known conflicts of interest are associated with this publication. There has been no significant financial support for this work that could have influenced its outcome. We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that all have approved the order of authors listed in our manuscript. We confirm that we have given due consideration to the protection of intellectual property associated with this work. There are no impediments to publication, including the timing of publication, concerning intellectual property. In so doing, we confirm that we have followed the regulations of our institutions concerning intellectual property. We further confirm that any aspect of the work covered in this manuscript that has involved either experimental animals or human patients has been conducted with the ethical approval of all relevant bodies and that such approvals are acknowledged within the manuscript. [Can be deleted if not relevant] We understand that the corresponding author is the sole contact for the editorial process (including editorial manager and direct communications with the office). They are responsible for communicating with the other authors about progress, submissions of revisions, and final approval of proofs. We confirm that we have provided a current, correct email address accessible by the corresponding author.

Consent to participate

Not applicable.

Consent for publication

The authors hereby declare that they participated in this study and the manuscript’s development models. They have read the final version and consent for the article to be published in this journal.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Piro, N.S., Mohammed, A.S., Hamad, S.M. et al. Electrical conductivity, microstructures, chemical compositions, and systematic multivariable models to evaluate the effect of waste slag smelting (pyrometallurgical) on the compressive strength of concrete. Environ Sci Pollut Res 29, 68488–68521 (2022). https://doi.org/10.1007/s11356-022-20518-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20518-1