Abstract

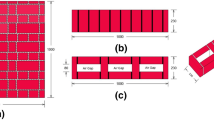

This work aims to enhance the energy cost-saving potential of conventional mud-brick by including natural waste materials as insulators. The solid waste materials considered for mud bricks are rice husk, sawdust, coir pith, and fly ash. This work investigates the structural and thermoeconomic performance of four types of insulated mud bricks and three roofs of ferrocement, clay, and ceramic materials. The thermal properties of walls and roofs were measured as per ASTM D 5334 standards. The utilization of solid waste in mud bricks enhanced the structural properties and air-conditioning cost-saving potential of the mud bricks. The results also showed the mitigation of greenhouse gas emissions with the usage of insulated bricks for buildings. The rice husk mud-brick wall showed better results of higher time lag, lower decrement factor, higher air-conditioning cost-savings, acceptable payback periods, and higher annual carbon mitigation values of 11.11 h, 0.24, 1.74 $/m2, 1.17 years, and 33.35 kg/kWh, respectively, among all the studied multilayer walls. Among the roofs, clay tile roof showed a lower decrement factor (0.989), higher time lag (0.73 h), higher air-conditioning cost-savings (2.58 $/m2), lower payback periods (0.61 years), and higher annual carbon mitigation (21.73 kg/kWh). The results are in designing eco-friendly and energy-efficient envelopes for buildings.

Similar content being viewed by others

Data availability

Not applicable

Abbreviations

- Cp :

-

specific heat (J/kg K)

- Cs :

-

total air-conditioning cost saving ($/m2)

- k :

-

thermal conductivity (W/mK)

- U :

-

transmittance (W/m2K)

- Z :

-

admittance (W/m2K)

- CoV:

-

coefficient of variance

- CPMBW:

-

coir pith mud-brick wall

- FAMBW:

-

fly ash mud-brick wall

- HCM:

-

heating carbon mitigation (kg/kWh)

- HCS:

-

heating cost-saving ($/m2)

- HDD:

-

heating degree-days (°C-days)

- MBWWI:

-

mud-brick wall without insulator

- MCPMBW:

-

multilayer coir pith mud-brick wall

- MFAMBW:

-

multilayer fly ash brick wall

- MRHMBW:

-

multilayer rice husk mud-brick wall

- MSWMBW:

-

multilayer sawdust mud-brick wall

- PB:

-

payback period (years)

- CCM:

-

cooling carbon mitigation

- CCS:

-

cooling cost-saving ($/m2)

- CDD:

-

cooling degree-days (°C-days)

- CETR:

-

ceramic tile roof

- CLTR:

-

clay tile roof

- CM:

-

carbon mitigation (kg/kWh)

- RHMBW:

-

rice husk mud-brick wall

- SD:

-

standard deviation

- SWMBW:

-

sawdust mud-brick wall

- TCM:

-

total carbon mitigation (kg/kWh)

- α :

-

thermal diffusivity (m2/s)

- μ :

-

decrement factor (-)

- ρ :

-

density (kg/m3)

- Φ :

-

time lag (h)

References

Al-Fakih A, Mohammed BS, Liew MS, Nikbakht E (2019) Incorporation of waste materials in the manufacture of masonry bricks: An update review. J Build Eng 21:37–54. https://doi.org/10.1016/j.jobe.2018.09.023

Asan H (2006) Numerical computation of time lags and decrement factors for different building materials. Build Environ 41:615–620. https://doi.org/10.1016/j.buildenv.2005.02.020

ASHRAE (2009) Climatic design information. ASHRAE Fundam Handbook,CHAPTER 14 Clim Des Inf Clim 128. https://doi.org/10.1016/0140-7007(79)90114-2

ASTM:C618-12a (2010) Standard specification for coal fly ash and raw or calcined natural pozzolan for use. 3–6. 10.1520/C0618-19.2

ASTM:C1167-11 (2017) Standard specification for clay roof tiles. 11:1–7. 10.1520/C1167-11R17.Copyright

ASTM:D5334-14 (2016) Standard test method for determination of thermal conductivity of soil and soft rock by Thermal needle probe procedure. 04:6–13. 10.1520/D5334-0814.2

Balaji NC, Mani M, Venkatarama Reddy BV (2019) Dynamic thermal performance of conventional and alternative building wall envelopes. J Build Eng 21:373–395. https://doi.org/10.1016/j.jobe.2018.11.002

Brasileiro GAM, Vieira JAR, Barreto LS (2013) Use of coir pith particles in composites with Portland cement. J Environ Manage 131:228–238. https://doi.org/10.1016/j.jenvman.2013.09.046

Chel A, Tiwari GN (2009) Performance evaluation and life cycle cost analysis of earth to air heat exchanger integrated with adobe building for New Delhi composite climate. Energy Build 41:56–66. https://doi.org/10.1016/j.enbuild.2008.07.006

Chel A, Tiwari GN (2009) Thermal performance and embodied energy analysis of a passive house - case study of vault roof mud-house in India. Appl Energy 86:1956–1969. https://doi.org/10.1016/j.apenergy.2008.12.033

Chen S, Yang Y, Olomi C, Zhu L (2020) Numerical study on the winter thermal performance and energy saving potential of thermo-activated PCM composite wall in existing buildings. Build Simul 237–256

Chiang K, Yen H, Lu C (2019) Recycled gypsum board acted as a mineral swelling agent for improving thermal conductivity characteristics in manufacturing of green lightweight building brick. Environ Sci Pollut Res 34205–34219

CIBSE (2006) CIBSE Environmental Design Guide A. The Chartered Institution of; Building Services Engineers London

Collet F, Serres L, Miriel J, Bart M (2006) Study of thermal behaviour of clay wall facing south. Build Environ 41:307–315. https://doi.org/10.1016/j.buildenv.2005.01.024

Dalkılıç N, Nabikoğlu A (2017) Traditional manufacturing of clay brick used in the historical buildings of Diyarbakir (Turkey). Front Archit Res 6:346–359. https://doi.org/10.1016/j.foar.2017.06.003

Daouas N (2011) A study on optimum insulation thickness in walls and energy savings in Tunisian buildings based on analytical calculation of cooling and heating transmission loads. Appl Energy 88:156–164. https://doi.org/10.1016/j.apenergy.2010.07.030

Davies M (2004) Building Heat Transfer. John Wiley & Sons Ltd,

De Silva GHMJS, Perera BVA (2018) Effect of waste rice husk ash (RHA) on structural, thermal and acoustic properties of fired clay bricks. J Build Eng 18:252–259. https://doi.org/10.1016/j.jobe.2018.03.019

De Silva GHMJS, Surangi MLC (2017) Effect of waste rice husk ash on structural, thermal and run-off properties of clay roof tiles. Constr Build Mater 154:251–257. https://doi.org/10.1016/j.conbuildmat.2017.07.169

Demirboǧa R (2003) Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build 35:189–192. https://doi.org/10.1016/S0378-7788(02)00052-X

ECBC (2017) Energy Conservation Building Code. Bureau of Energy Efficiency, New Delhi

El Fgaier F, Lafhaj Z, Brachelet F et al (2015) Thermal performance of unfired clay bricks used in construction in the north of France: case study. Case Stud Constr Mater 3:102–111. https://doi.org/10.1016/j.cscm.2015.09.001

Eliche-Quesada D, Felipe-Sesé MA, López-Pérez JA, Infantes-Molina A (2017) Characterization and evaluation of rice husk ash and wood ash in sustainable clay matrix bricks. Ceram Int 43:463–475. https://doi.org/10.1016/j.ceramint.2016.09.181

Forget MCL, Regev L, Friesem DE, Shahack-Gross R (2015) Physical and mineralogical properties of experimentally heated chaff-tempered mud bricks: implications for reconstruction of environmental factors influencing the appearance of mud bricks in archaeological conflagration events. J Archaeol Sci Reports 2:80–93. https://doi.org/10.1016/j.jasrep.2015.01.008

Gourav K, Balaji NC, Venkatarama Reddy BV, Mani M (2017) Studies into structural and thermal properties of building envelope materials. Energy Procedia 122:104–108. https://doi.org/10.1016/j.egypro.2017.08.037

GRIHA (2011) Technical manual for trainers on building and system design optimization renewable energy application. TERI, India

Haque S (2019) Sustainable use of plastic brick from waste PET plastic bottle as building block in Rohingya refugee camp : a review. Environ Sci Pollut Res 26:36163–36183

Hemalatha T, Ramaswamy A (2017) A review on fly ash characteristics – towards promoting high volume utilization in developing sustainable concrete. J Clean Prod 147:546–559. https://doi.org/10.1016/j.jclepro.2017.01.114

Holman JP (2012) Experimental methods for engineers. McGraw-Hill Companies

IS:1077 (1992) Common burnt clay building bricks - specification

IS:1528 (2007) Methods of sampling and physical tests for refractory materials

IS:13356 (1992) Precast ferrocement water tanks upto 10000litres capacity- specification

IS:1727 (1967) Methods of test for pozzolanic materials

IS:2185 (2005) Concrete masonry units — specification, Part 1 hollow and solid concrete blocks

IS:3495 (2019) Methods of tests of burnt clay building bricks

IS:654 (1992) Clay roofing tiles, mangalore pattern-specification

Jin X, Zhang X, Cao Y, Wang G (2012) Thermal performance evaluation of the wall using heat flux time lag and decrement factor. Energy Build 47:369–374. https://doi.org/10.1016/j.enbuild.2011.12.010

Kumar D, Zou PXW, Memon RA, Alam MDM, Sanjayan JG, Kumar S (2020) Life-cycle cost analysis of building wall and insulation materials. J Build Phys 43:428–455. https://doi.org/10.1177/1744259119857749

Kumar K, Saboor S, Kumar V et al (2018) Experimental and theoretical studies of various solar control window glasses for the reduction of cooling and heating loads in buildings across different climatic regions. Energy Build 173:326–336. https://doi.org/10.1016/j.enbuild.2018.05.054

Leo Samuel DG, Dharmasastha K, Shiva Nagendra SM, Maiya MP (2017) Thermal comfort in traditional buildings composed of local and modern construction materials. Int J Sustain Built Environ 6:463–475. https://doi.org/10.1016/j.ijsbe.2017.08.001

Lertsatitthanakorn C, Atthajariyakul S, Soponronnarit S (2009) Techno-economical evaluation of a rice husk ash (RHA) based sand-cement block for reducing solar conduction heat gain to a building. Constr Build Mater 23:364–369. https://doi.org/10.1016/j.conbuildmat.2007.11.017

Madrid M, Orbe A, Carré H, García Y (2018) Thermal performance of sawdust and lime-mud concrete masonry units. Constr Build Mater 169:113–123. https://doi.org/10.1016/j.conbuildmat.2018.02.193

Madurwar MV, Ralegaonkar RV, Mandavgane SA (2013) Application of agro-waste for sustainable construction materials: a review. Constr Build Mater 38:872–878. https://doi.org/10.1016/j.conbuildmat.2012.09.011

Nematchoua MK, Raminosoa CRR, Mamiharijaona R, René T, Orosa JA, Elvis W, Meukam P (2015) Study of the economical and optimum thermal insulation thickness for buildings in a wet and hot tropical climate: case of Cameroon. Renew Sustain Energy Rev 50:1192–1202. https://doi.org/10.1016/j.rser.2015.05.066

Oskouei AV, Afzali M, Madadipour M (2017) Experimental investigation on mud bricks reinforced with natural additives under compressive and tensile tests. Constr Build Mater 142:137–147. https://doi.org/10.1016/j.conbuildmat.2017.03.065

Pappu A, Saxena M, Asolekar SR (2007) Solid wastes generation in India and their recycling potential in building materials. Build Environ 42:2311–2320. https://doi.org/10.1016/j.buildenv.2006.04.015

Petersdorff C, Boermans T, Harnisch J (2006) Mitigation of CO 2 emissions from the EU-15 building stock beyond the EU Directive on the energy performance of buildings. Environ Sci Pollut Res 13:350–358

Sasui S, Warcharin J (2016) Comparing the effects of straw and rice husk on the durability of mud brick. In proceedings of 5th International Conference on Energy, Environment and Sustainable Development, 159-166.

Shafigh P, Asadi I, Mahyuddin NB (2018) Concrete as a thermal mass material for building applications - a review. J Build Eng 19:14–25. https://doi.org/10.1016/j.jobe.2018.04.021

Shaik S, Talanki ABPS (2016) Optimizing the position of insulating materials in flat roofs exposed to sunshine to gain minimum heat into buildings under periodic heat transfer conditions. Environ Sci Pollut Res 23:9334–9344. https://doi.org/10.1007/s11356-015-5316-7

Shaik S, Talanki Puttaranga Setty AB (2016) Influence of ambient air relative humidity and temperature on thermal properties and unsteady thermal response characteristics of laterite wall houses. Build Environ 99:170–183. https://doi.org/10.1016/j.buildenv.2016.01.030

Shi Y, Li Y, Tang Y, Yuan X (2020) Life cycle assessment of autoclaved aerated fly ash and concrete block production : a case study in China. Environ Sci Pollut Res 25432–25444

Shibib KS, Qatta HI, Hamza MS (2013) Enhancement in thermal and mechanical properties of bricks. Therm Sci 17:1119–1123. https://doi.org/10.2298/TSCI110610043S

Turgut P, Murat Algin H (2007) Limestone dust and wood sawdust as brick material. Build Environ 42:3399–3403. https://doi.org/10.1016/j.buildenv.2006.08.012

Ulgen K (2002) Experimental and theoretical investigation of effects of wall’s thermophysical properties on time lag and decrement factor. Energy Build 34:273–278. https://doi.org/10.1016/S0378-7788(01)00087-1

Vijaykumar KCK, Srinivasan PSS, Dhandapani S (2007) A performance of hollow clay tile (HCT) laid reinforced cement concrete (RCC) roof for tropical summer climates. Energy Build 39:886–892. https://doi.org/10.1016/j.enbuild.2006.05.009

Yu J, Yang C, Tian L, Liao D (2009) A study on optimum insulation thicknesses of external walls in hot summer and cold winter zone of China. Appl Energy 86:2520–2529. https://doi.org/10.1016/j.apenergy.2009.03.010

Zhang L (2013) Production of bricks from waste materials - a review. Constr Build Mater 47:643–655. https://doi.org/10.1016/j.conbuildmat.2013.05.043

Zhang Z, Wong YC, Arulrajah A, Horpibulsuk S (2018) A review of studies on bricks using alternative materials and approaches. Constr Build Mater 188:1101–1118. https://doi.org/10.1016/j.conbuildmat.2018.08.152

Author information

Authors and Affiliations

Contributions

Formal analysis and Investigation: Chelliah Arumugam. Writing—original draft preparation: Chelliah Arumugam. Conceptualization: Saboor Shaik. Methodology: Saboor Shaik. Resources: Saboor Shaik. Supervision: Saboor Shaik. Writing—review and editing: Saboor Shaik.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent to Publish

Not applicable

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Responsible Editor: Philipp Gariguess

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arumugam, C., Shaik, S. Transforming waste disposals into building materials to investigate energy savings and carbon emission mitigation potential. Environ Sci Pollut Res 28, 15259–15273 (2021). https://doi.org/10.1007/s11356-020-11693-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-11693-0