Abstract

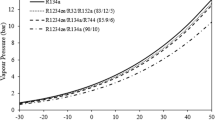

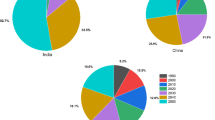

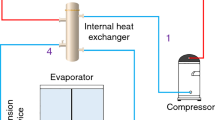

The main aim of this present investigation is to evaluate performance and environmental impact analysis of various novel mixture refrigerants as R22 replacements theoretically. Refrigerants with lower global warming potential (GWP) can be adequate for bringing down emissions which are concerned for air conditioners. In this investigation, twenty-seven refrigerants were developed at several compositions. Important studies such as computation of CO2 emissions using total equivalent warming impact (TEWI), toxicity and flammability analysis of various considered refrigerants were also carried out in this investigation. Performance analysis of refrigerants was conducted under different operating conditions. Results showed that the energy efficiency ratios (EERs) of refrigerants such as R1270, RM30 (R152a/R1270/RE170 of 25/71/4 by mass percentage) and RM50 (R152a/R1270/RE170 of 10/85/5 by mass percentage) were closer to that of R22 and they are relatively lower than R22 by 0.95%, 1.34% and 1.80%, respectively. Toxicity investigation exhibited that all the refrigerants studied were classified into nontoxic category (A) whereas flammability investigation revealed that all the novel refrigerant mixtures (RM10 to RM50) were classified into flammable category (A3). CO2 emissions (TEWI) released from air conditioner working with R1270, RM30 and RM50 were 7.41%, 6.85% and 6.51%, respectively, lower than that of R22. In terms of several thermodynamic aspects, the performance of refrigerants such as R1270, RM30 and RM50 were superior to those of R22 and its various considered alternatives working under different operating conditions, although their EERs are fairly lower than R22 and hence, these refrigerants could be considered suitable environment-friendly alternatives to R22 used in air conditioners. The present study gives essential information and a road map towards the development of low GWP R22 alternative refrigerant blends from the viewpoint of toxicity, flammability, performance aspects, environmental and safety aspects, respectively.

Similar content being viewed by others

Abbreviations

- BP:

-

boiling point (°C)

- CHR:

-

condenser heat rejection (kJ/kg)

- E An :

-

energy consumption per year (kWh)

- GWP100 :

-

global warming potential for a time horizon of 100 years

- h :

-

enthalpy (kJ/kg)

- h 1 :

-

enthalpy at compressor inlet (kJ/kg)

- h 1i :

-

enthalpy at evaporator exit (kJ/kg)

- h 2 :

-

enthalpy at compressor outlet (kJ/kg)

- h 2h :

-

enthalpy at condenser inlet (kJ/kg)

- h 3g :

-

enthalpy at condenser outlet (kJ/kg)

- h 4 :

-

enthalpy at evaporator entry (kJ/kg)

- h f1 :

-

enthalpy of the refrigerant at bubble point of condensing process (kJ/kg)

- h f2 :

-

enthalpy of the subcooled refrigerant liquid entering the expansion process (kJ/kg)

- h g1 :

-

enthalpy of the refrigerant gas entering the compression process (kJ/kg)

- h g2 :

-

enthalpy of the refrigerant gas leaving the compression process (kJ/kg)

- HOC:

-

heat of combustion (kJ/mol)

- L :

-

leakage rate per year (%)

- LFL:

-

lower flammability limit (kg/m3)

- m :

-

mass of refrigerant charge (kg)

- \( \dot{m} \) :

-

mass flow rate of refrigerant (kg/s)

- MW:

-

molecular weight (kg/kmol)

- OEL:

-

occupational exposure limit (ppm)

- P :

-

pressure (MPa)

- P c :

-

critical pressure (MPa)

- P comp :

-

compressor power (kW)

- P e :

-

evaporating pressure (MPa)

- P g1 :

-

dew point pressure at compressor suction (MPa)

- P g2 :

-

dew point pressure at compressor discharge (MPa)

- P k :

-

condensing pressure (MPa)

- P r :

-

pressure ratio (dimensionless)

- PPTR:

-

power spent per ton of refrigeration (kW/TR)

- Q c :

-

capacity of the system (kW)

- RE:

-

refrigeration effect (kJ/kg)

- S Life :

-

service life of the device (years)

- t e" :

-

dew point temperature at evaporation process (°C)

- t e1 :

-

temperature at entry of evaporation process (°C)

- t e, m :

-

mean evaporating temperature (°C)

- t f1 :

-

temperature of the refrigerant at bubble point of condensing process (°C)

- t f2 :

-

temperature of subcooled refrigerant liquid entering the expansion process (°C)

- t k′ :

-

bubble point temperature at condensation process (°C)

- t k" :

-

dew point temperature at condensation process (°C)

- t k, m :

-

mean condensing temperature (°C)

- T :

-

temperature (°C)

- T bub :

-

bubble point temperature (°C)

- T c :

-

critical temperature (K)

- T d :

-

compressor discharge temperature (°C)

- T dew :

-

dew point temperature (°C)

- T e :

-

evaporating temperature (°C)

- T glide :

-

temperature glide (°C)

- T k :

-

condensing temperature (°C)

- TEWI:

-

total equivalent warming impact (kg CO2e)

- UFL:

-

upper flammability limit (kg/m3)

- VRC:

-

volumetric refrigeration capacity (kJ/m3)

- W ac :

-

actual compressor work (kJ/kg)

- W c :

-

isentropic compressor work (kJ/kg)

- α recovery :

-

recyling factor (dimensionless)

- ß :

-

indirect emission factor (kg CO2e/kWh)

- η c :

-

compression efficiency (%)

- ρ :

-

density (kg/m3)

- ρ 1i :

-

vapour density at compressor inlet (kg/m3)

- ∆T sub :

-

degree of subcooling (°C)

- ∆T sup :

-

degree of superheating (°C)

- AHRI:

-

Air-Conditioning, Heating, and Refrigeration Institute

- ASHRAE:

-

American Society of Heating, Refrigerating and Air-Conditioning Engineers

- BEE:

-

Bureau of Energy Efficiency

- BP:

-

boiling point

- CHR:

-

condenser heat rejection

- EER:

-

energy efficiency ratio

- EN:

-

European norm

- GWP:

-

global warming potential

- HCs:

-

hydrocarbons

- HCFCs:

-

hydrochlorofluorocarbons

- HFCs:

-

hydrofluorocarbons

- IEC:

-

International Electrotechnical Commission

- IIR:

-

International Institute of Refrigeration

- ISO:

-

International Organization for Standardization

- ODP:

-

ozone depletion potential

- RE:

-

refrigeration effect

- RF:

-

refrigerant flammability

- RM:

-

refrigerant mixture

- TEWI:

-

total equivalent warming impact

- TR:

-

ton of refrigeration

- VCR:

-

vapour compression refrigeration

- VRC:

-

volumetric refrigeration capacity

References

Abdelaziz O, Shrestha S (2016) Soft-optimized system test of alternative lower GWP refrigerants in 1.5-ton mini-split air conditioning units. AHRI-AREP Test Report No.62

Ahamed JU, Saidur R, Masjuki HH (2014) Investigation of environmental and heat transfer analysis of air conditioner using hydrocarbon mixture compared to R22. Arab J Sci Eng 39:4141–4150. https://doi.org/10.1007/s13369-014-0961-6

AHRI Standard 540 (2015) Performance rating of positive displacement refrigerant compressors and compressor units, USA.

AHRI (2016) AHRI low-GWP alternative refrigerants evaluation program. Available at: http://ahrinet.org/site/514/Resources/Research/AHRI-Low-GWP-Alternative-Refrigerants-Evaluation.

Aized T, Hamza A (2019) Thermodynamic analysis of various refrigerants for automotive air conditioning system. Arab J Sci Eng 44:1697–1707. https://doi.org/10.1007/s13369-018-3646-8

Alkhaledi KA, Means K (2018) A study on the use of propane (R-290) in vending machines as a substitute for R-134a to minimise the global warming potential. Int J Glob Warm 4:131–141. https://doi.org/10.1504/IJGW.2018.088650

Ananthanarayanan PN (2013) Basic refrigeration and air conditioning. McGraw-Hill Education, New Delhi, INDIA

Antunes AHP, Bandarra Filho EP (2016) Experimental investigation on the performance and global environmental impact of a refrigeration system retrofitted with alternative refrigerants. Int J Refrigeration 70:119–127. https://doi.org/10.1016/j.ijrefrig.2016.06.027

Aprea C, Mastrullo R, Renno C, Vanoli GP (2004) An evaluation of R22 substitutes performances regulating continuously the compressor refrigeration capacity. Appl Therm Eng 24:127–139. https://doi.org/10.1016/S1359-4311(03)00187-X

Arora CP (2010) Refrigeration and air conditioning. Tata McGraw-Hill, New Delhi, INDIA

Arora RC (2012) Refrigeration and air conditioning. PHI Learning Private Limited, New Delhi, INDIA

Arora A, Kaushik SC (2008) Theoretical analysis of a vapour compression refrigeration system with R502, R404A and R507A. Int J Refrigeration 31:998–1005. https://doi.org/10.1016/j.ijrefrig.2007.12.015

Arora A, Sachdev HL (2009) Thermodynamic analysis of R422 series refrigerants as alternative refrigerants to HCFC22 in a vapour compression refrigeration system. Int J Energy Res 33:753–765. https://doi.org/10.1002/er.1508

Arora A, Arora BB, Pathak BD, Sachdev HL (2007) Exergy analysis of a vapour compression refrigeration system with R-22, R-407C and R-410A. Int J Exergy 4:441–454. https://doi.org/10.1504/IJEX.2007.015083

ASHRAE (2017) Refrigerants Ch. 29, pp. 29.1–29.12, ASHRAE Handbook-Fundamentals, Atlanta, USA.

ASHRAE Standard 34 (2013) Designation and safety classification of refrigerants. ASHRAE, Atlanta, USA

Babu TP, Samaje VV, Rajeev R (2006) Development of zero ODP, less TEWI, binary, ternary and quaternary mixtures to replace HCFC-22 in window air-conditioner. In: Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue, USA

Bentivegni M, Clodic D (2011) R1234yf Mixtures for replacing R-407C in residential heat pumps. In Proceedings of the 10th International Energy Agency Heat Pump Conference, Tokyo, Japan.

Bitzer (2018) Refrigerant report 20, Sindelfingen, Germany. Available at: https://www.bitzer-refrigerantreport.com/fileadmin/user_upload/A-501-20.pdf

Bolaji BO (2011) Performance investigation of ozone-friendly R404A and R507 refrigerants as alternatives to R22 in a window air conditioner. Energy Build 43:3139–3143. https://doi.org/10.1016/j.enbuild.2011.08.011

Cengel YA, Boles MA, Kanoglu M (2019) Thermodynamics: an engineering approach. McGraw-Hill Education, New York

Chen W (2008) A comparative study on the performance and environmental characteristics of R410A and R22 residential air conditioners. Appl Therm Eng 28:1–7. https://doi.org/10.1016/j.applthermaleng.2007.07.018

Chen JB, Li H, Ji CY, Xi L (2011) Performance of a split-type air conditioner with natural refrigerant R1270 to replace R22. Adv Mater Res 243:4979–4982. https://doi.org/10.4028/www.scientific.net/AMR.243-249.4979

Chen X, Liu C, Yang J, Chen J (2018) Experimental study on R-22, R-427A, R-161 and R-290 in air-source heat pump for space heating at low ambient temperatures. Int J Refrigeration 96:147–154. https://doi.org/10.1016/j.ijrefrig.2018.08.021

Dalkilic AS, Wongwises S (2010) A performance comparison of vapour-compression refrigeration system using various alternative refrigerants. Int Commun Heat Mass Transfer 37:1340–1349. https://doi.org/10.1016/j.icheatmasstransfer.2010.07.006

Davies TW, Caretta O (2004) A low carbon, low TEWI refrigeration system design. Appl Therm Eng 24:1119–1128. https://doi.org/10.1016/j.applthermaleng.2003.12.026

Devecioğlu AG (2017) Seasonal performance assessment of refrigerants with low GWP as substitutes for R410A in heat pump air conditioning devices. Appl Therm Eng 125:401–411. https://doi.org/10.1016/j.applthermaleng.2017.07.034

Devecioğlu AG, Oruç V (2015) Characteristics of some new generation refrigerants with low GWP. Energy Procedia 75:1452–1457. https://doi.org/10.1016/j.egypro.2015.07.258

Devotta S, Waghmare AV, Sawant NN, Domkundwar BM (2001) Alternatives to HCFC-22 for air conditioners. Appl Therm Eng 21:703–715. https://doi.org/10.1016/S1359-4311(00)00079-X

Devotta S, Padalkar AS, Sane NK (2005) Performance assessment of HC-290 as a drop-in substitute to HCFC-22 in a window air conditioner. Int J Refrigeration 28:594–604. https://doi.org/10.1016/j.ijrefrig.2004.09.013

Dincer I (2017) Refrigeration systems and applications. Wiley, England

European Standard EN 378-1:(2016a) Refrigerating systems and heat pumps. Safety and environmental requirements-Part 1: Basic requirements, definitions, classification and selection criteria, European Committee for Standardization, Brussels, Belgium

European Standard EN 60335-2-40:(2016b) Safety of household and similar electrical appliances -Part 2-40: Particular requirements for electrical heat pumps, airconditioners and dehumidifiers. European Committee for Standardization, Brussels, Belgium

Harby K (2017) Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: an updated overview. Renew Sust Energ Rev 73:1247–1264. https://doi.org/10.1016/j.rser.2017.02.039

Harnisch J, de Jager D, Gale J, Stobbe O (2002) Halogenated compounds and climate change. Environ Sci Pollut R 9:369–374. https://doi.org/10.1007/BF02987583

Hwang Y, Gado A, Radermacher R (2003) Performance propane in a unitary heat pump. In: Proceedings of the 21st International congress of refrigeration, Washington, DC, USA

International Electrotechnical Commission IEC 60335-2-40: (2016) Safety of household and similar electrical appliances - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers. International Electrotechnical Commission,Geneva, Switzerland

International Institute of Refrigeration (1997) Standards for flammable refrigerants. Thirteenth informatory note on refrigerants. France, Paris

International Organization for Standardization ISO 5149-2:(2014) Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design, construction, testing, marking and documentation. International Organization for Standardization ,Geneva, Switzerland

Kondo S, Takahashi A, Tokuhashi K, Sekiya A (2002) RF number as a new index for assessing combustion hazard of flammable gases. J Hazard Mater 93:259–267. https://doi.org/10.1016/S0304-3894(02)00117-6

La Rocca V, Panno G (2011) Experimental performance evaluation of a vapour compression refrigerating plant when replacing R22 with alternative refrigerants. Appl Energy 88:2809–2815. https://doi.org/10.1016/j.apenergy.2011.01.051

Lemmon EW, McLinden MO, Huber ML (2013) NIST reference fluids thermodynamic and transport properties REFPROP 9.1. In: National Institute of Standards and Technology (NIST), USA, Gaithersburg, MD

Meng Z, Zhang H, Qiu J, Lei M (2016) Theoretical analysis of R1234ze (E), R152a, and R1234ze (E)/R152a mixtures as replacements of R134a in vapour compression system. Adv Mech Eng 8:1–10. https://doi.org/10.1177/1687814016676945

Mohanraj M (2018) Experimental investigations on R430A as a drop-in substitute for R134a in domestic refrigerators. Proc Inst Mech Eng Part E J Process Mech Eng 233:728–738. https://doi.org/10.1177/0954408918796369

Mohanraj M, Jayaraj S, Muraleedharan C (2009) Environment friendly alternatives to halogenated refrigerants-a review. Int J Greenh Gas Control 3:108–119. https://doi.org/10.1016/j.ijggc.2008.07.003

Oruç V, Devecioğlu AG, Berk U, Vural İ (2016) Experimental comparison of the energy parameters of HFCs used as alternatives to HCFC-22 in split type air conditioners. Int J Refrigeration 63:125–132. https://doi.org/10.1016/j.ijrefrig.2015.11.004

Padalkar A, Mali K, Devotta S (2011) Simulated performance of R290 in air conditioner. In: Proceedings of the 23rd International congress refrigeration, Czech Republic

Padalkar AS, Mali KV, Devotta S (2014) Simulated and experimental performance of split packaged air conditioner using refrigerant HC-290 as a substitute for HCFC-22. Appl Therm Eng 62:277–284. https://doi.org/10.1016/j.applthermaleng.2013.09.017

Powell RL (2002) CFC phase-out: have we met the challenge? J Fluor Chem 114:237–250. https://doi.org/10.1016/S0022-1139(02)00030-1

Raj MH, Lal DM (2008) A comparative study on the performance of a R22 window air conditioner retrofitted with R407C/R290/R600a refrigerant mixture. Int J Ambient Energy 29:207–217. https://doi.org/10.1080/01430750.2008.9675079

Sánchez D, Cabello R, Llopis R, Arauzo I, Catalán-Gil J, Torrella E (2017) Energy performance evaluation of R1234yf, R1234ze (E), R600a, R290 and R152a as low-GWP R134a alternatives. Int J Refrigeration 74:269–282. https://doi.org/10.1016/j.ijrefrig.2016.09.020

Schultz K, Kujak S (2012) System drop-in tests of R22 alternative fluids (ARM-32a, DR-7, L-20, LTR4X, LTR6A and D52Y) in a 5-RT Air-Cooled Water Chiller (Cooling Mode). Air-conditioning, heating, and refrigeration institute low-gwp alternative refrigerants evaluation program, Report No.6.

Shaik SV, Babu TPA (2018) Thermodynamic performance analysis and flammability study of various new ozone friendly non azeotropic refrigerant mixtures as alternatives to replace R22 used in residential air conditioners. Int J Heat Tech 36:1470–1481. https://doi.org/10.18280/ijht.360441

Shaik SV, Babu TPA (2020) Theoretical thermodynamic performance assessment of various environment-friendly novel refrigerants used in refrigeration systems. Proc Inst Mech Eng C J Mech Eng Sci 234:914–934. https://doi.org/10.1177/0954406219884968

Tian Q, Cai D, Ren L, Tang W, Xie Y, He G, Liu F (2015) An experimental investigation of refrigerant mixture R32/R290 as drop-in replacement for HFC410A in household air conditioners. Int J Refrigeration 57:216–228. https://doi.org/10.1016/j.ijrefrig.2015.05.005

UNEP (1997) Montreal Protocol on substances that deplete the ozone layer Final Act. United Nation Environment Program, New York, USA

UNFCCC (1997) Kyoto Protocol, Report of the Conference of the Parties. United Nations Framework Convention on Climate Change, New York, USA

Wang F, Fan X, Lian Z, Wang F, Zhang X (2012) Performance assessment of heat pumps using HFC125/HCs mixtures. Int J Energy Res 36:1005–1014. https://doi.org/10.1002/er.1852

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shaik, S.V., Shaik, S., Gorantla, K. et al. Investigation on thermodynamic performance analysis and environmental effects of various new refrigerants used in air conditioners. Environ Sci Pollut Res 27, 41415–41436 (2020). https://doi.org/10.1007/s11356-020-09478-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09478-6