Abstract

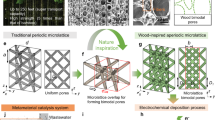

With the exacerbation of industrialization, water treatment has become a necessary step for the eradication of dyes, heavy metals, oils, pharmaceuticals, and illicit drugs. These pollutants pose an impending threat to the health of humans by causing chronic or acute poisoning. Albeit they are noxious, the presence of some metals in lower concentrations is indispensable for human health. 3D printing (additive manufacturing) (3DP) can contrive nearly any complicated geometric form in a wide array of objects among various scales by a layer-wise method of manufacturing, which is more indubitably designed than any other conventional method. 3DP could remodel the existing patterns of membrane housing and possibly trim down the power demand and chemical use in saltwater desalinating and wastewater purification plants. Membranes that are 3D printed with correctly arranged apertures and shapes enhance material transport and flow athwart the surface of the membrane and at once lessen membrane soiling. This kind of technology forges membranes of polymers, biopolymers, alloys, metals, and ceramics via computer-aided design (CAD). A polylactic acid porous super-hydrophobic membrane with pore size in the range 40–600 μm showed 99.4% oil-water separating power and 60 kL h−1 m−2 flux when the pore size was tuned to 250 μm via CAD-aided 3D printing technology. This review focuses on the ability of 3D-printed membranes for the efficient removal of toxic pollutants from wastewater.

3D-printed membranes for water treatment

Similar content being viewed by others

References

Afshar-Mohajer N, Wu C-Y, Ladun T et al (2015) Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build Environ 93:293–301. https://doi.org/10.1016/j.buildenv.2015.07.013

Alaimo G, Marconi S, Costato L, Auricchio F (2017) Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos Part B Eng 113:371–380. https://doi.org/10.1016/j.compositesb.2017.01.019

Amin R, Knowlton S, Hart A et al (2016) 3D-printed microfluidic devices. Biofabrication 8:1–16. https://doi.org/10.1088/1758-5090/8/2/022001

Amjad Z (1993) Reverse osmosis : membrane technology, water chemistry & industrial applications. Van Nostrand Reinhold, New York

Apel P (2001) Track etching technique in membrane technology. Radiat Meas 34:559–566. https://doi.org/10.1016/S1350-4487(01)00228-1

Arora R, Singh N, Balasubramanian K, Alegaonkar P (2014) Electroless nickel coated nano-clay for electrolytic removal of Hg(ii) ions. RSC Adv 4:50614–50623. https://doi.org/10.1039/c4ra06988a

Badalov S, Oren Y, Arnusch CJ (2015) Ink-jet printing assisted fabrication of patterned thin film composite membranes. J Membr Sci 493:508–514. https://doi.org/10.1016/j.memsci.2015.06.051

Balogun HA, Sulaiman R, Marzouk SS et al (2019) 3D printing and surface imprinting technologies for water treatment: a review. J Water Process Eng 31:100786. https://doi.org/10.1016/j.jwpe.2019.100786

Becquer T, Quantin C, Sicot M, Boudot J (2003) Chromium availability in ultramafic soils from New Caledonia. Sci Total Environ 301:251–261. https://doi.org/10.1016/S0048-9697(02)00298-X

Berlin M, Zalups RK, Fowler BA (2015) Mercury. In: Handbook on the toxicology of metals. Elsevier, pp 1013–1075

Berman B (2012) 3-D printing: the new industrial revolution. Bus Horiz 55:155–162. https://doi.org/10.1016/j.bushor.2011.11.003

Bernhoft RA (2012) Mercury toxicity and treatment: a review of the literature. J Environ Public Health 2012:1–10. https://doi.org/10.1155/2012/460508

Berry E, Brown JM, Connell M et al (1997) Preliminary experience with medical applications of rapid prototyping by selective laser sintering. Med Eng Phys 19:90–96. https://doi.org/10.1016/S1350-4533(96)00039-2

Bhalara PD, Punetha D, Balasubramanian K (2014) A review of potential remediation techniques for uranium(VI) ion retrieval from contaminated aqueous environment. J Environ Chem Eng 2:1621–1634. https://doi.org/10.1016/j.jece.2014.06.007

Bikas H, Stavropoulos P, Chryssolouris G (2016) Additive manufacturing methods and modelling approaches: a critical review. Int J Adv Manuf Technol 83:389–405. https://doi.org/10.1007/s00170-015-7576-2

Bui N-N, Arena JT, McCutcheon JR (2015) Proper accounting of mass transfer resistances in forward osmosis: improving the accuracy of model predictions of structural parameter. J Membr Sci 492:289–302. https://doi.org/10.1016/j.memsci.2015.02.001

Chowdhury MR, Steffes J, Huey BD, McCutcheon JR (2018) 3D printed polyamide membranes for desalination. Science (80-) 361:682–686. https://doi.org/10.1126/science.aar2122

Chua CK, Chou SM, Wong TS (1998) A study of the state-of-the-art rapid prototyping technologies. Int J Adv Manuf Technol 14:146–152. https://doi.org/10.1007/BF01322222

Chua CK, Yeong WY, An J (2017) 3D Printing and Bioprinting in MEMS Technology. Micromachines 8:229. https://doi.org/10.3390/mi8070229

Davis A, Balasubramanian K (2016) Bioactive hybrid composite membrane with enhanced antimicrobial properties for biomedical applications. Def Sci J 66:434–438. https://doi.org/10.14429/dsj.66.10218

Deoray N, Kandasubramanian B (2018) Review on three-dimensionally emulated fiber-embedded lactic acid polymer composites: opportunities in engineering sector. Polym-Plast Technol Eng 57:860–874. https://doi.org/10.1080/03602559.2017.1354226

Dommati H, Ray SS, Wang J-C, Chen S-S (2019) A comprehensive review of recent developments in 3D printing technique for ceramic membrane fabrication for water purification. RSC Adv 9:16869–16883. https://doi.org/10.1039/C9RA00872A

Farrell WJ, Peggy OD, Colklin M (2001) Electrochemical and spectroscopic study of arsenate removal from water using zero-valent iron media. Environ Sci Technol 35(10):2026–2032

Ferguson JF, Gavis J (1972) A review of the arsenic cycle in natural waters. Water Res 6:1259–1274. https://doi.org/10.1016/0043-1354(72)90052-8

Gautam RK, Sharma SK, Mahiya SCM (2014) Contamination of heavy metals in aquatic media: transport, toxicity, and technologies for remediation. In: Sharma S (ed) Heavy metals in water: presence, removal and safety. The Royal Society of Chemistry, pp 1–24

Gautam A, Gore PM, Kandasubramanian B (2020) Nanocluster materials in photosynthetic machines. Chem Eng J 385:123951. https://doi.org/10.1016/j.cej.2019.123951

Gharde S, Goud R, Nimje S, Kandasubramanian B (2019a) 6. Aggrandized flexural properties of assorted natural biological materials. In: Kumar K, Davim JP (eds) Biodegradable composites. De Gruyter, Berlin, pp 111–140

Gharde S, Surendren A, Korde JM et al (2019b) Recent advances in additive manufacturing of bio-inspired materials. In: Biomanufacturing. Springer International Publishing, Cham, pp 35–68

Gibson I, Rosen D, Stucker B (2015) Additive manufacturing technologies. Springer, New York, NY

Giwa A, Akther N, Dufour V, Hasan SW (2016) A critical review on recent polymeric and nano-enhanced membranes for reverse osmosis. RSC Adv 6:8134–8163. https://doi.org/10.1039/C5RA17221G

Gnanasekaran K, Heijmans T, van Bennekom S et al (2017) 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl Mater Today 9:21–28. https://doi.org/10.1016/j.apmt.2017.04.003

Gonte RR, Balasubramanian K (2012) Chemically modified polymer beads for sorption of gold from waste gold solution. J Hazard Mater 217–218:447–451. https://doi.org/10.1016/j.jhazmat.2012.03.020

Gonte RR, Balasubramanian K, Mumbrekar JD (2013) Porous and cross-linked cellulose beads for toxic metal ion removal: Hg(II) ions. J Polym 2013:1–9. https://doi.org/10.1155/2013/309136

Gonte RR, Shelar G, Balasubramanian K (2014) Polymer–agro-waste composites for removal of Congo red dye from wastewater: adsorption isotherms and kinetics. Desalin Water Treat 52:7797–7811. https://doi.org/10.1080/19443994.2013.833876

Gore PM, Kandasubramanian B (2018) Heterogeneous wettable cotton based superhydrophobic Janus biofabric engineered with PLA/functionalized-organoclay microfibers for efficient oil–water separation. J Mater Chem A 6:7457–7479. https://doi.org/10.1039/C7TA11260B

Gore PM, Dhanshetty M, Kandasubramanian B (2016a) Bionic creation of nano-engineered Janus fabric for selective oil/organic solvent absorption. RSC Adv 6:111250–111260. https://doi.org/10.1039/C6RA24106A

Gore PM, Zachariah S, Gupta P, Balasubramanian K (2016b) Multifunctional nano-engineered and bio-mimicking smart superhydrophobic reticulated ABS/fumed silica composite thin films with heat-sinking applications. RSC Adv 6:105180–105191. https://doi.org/10.1039/c6ra16781k

Gore P, Khraisheh M, Kandasubramanian B (2018a) Nanofibers of resorcinol–formaldehyde for effective adsorption of As (III) ions from mimicked effluents. Environ Sci Pollut Res 25:11729–11745. https://doi.org/10.1007/s11356-018-1304-z

Gore PM, Khurana L, Siddique S et al (2018b) Ion-imprinted electrospun nanofibers of chitosan/1-butyl-3-methylimidazolium tetrafluoroborate for the dynamic expulsion of thorium (IV) ions from mimicked effluents. Environ Sci Pollut Res 25:3320–3334. https://doi.org/10.1007/s11356-017-0618-6

Gore PM, Naebe M, Wang X, Kandasubramanian B (2019a) Progress in silk materials for integrated water treatments: fabrication, modification and applications. Chem Eng J 374:437–470. https://doi.org/10.1016/j.cej.2019.05.163

Gore PM, Naebe M, Wang X, Kandasubramanian B (2019b) Silk fibres exhibiting biodegradability & superhydrophobicity for recovery of petroleum oils from oily wastewater. J Hazard Mater 121823. https://doi.org/10.1016/j.jhazmat.2019.121823

Gore PM, Purushothaman A, Naebe M et al (2019c) Nanotechnology for oil-water separation. In: Advanced research in nanosciences for water technology. Springer, Cham, pp 299–339. https://doi.org/10.1007/978-3-030-02381-2_14

Guo N, Leu MC (2013) Additive manufacturing: technology, applications and research needs. Front Mech Eng:215–243

Gupta P, Kandasubramanian B (2017) Directional fluid gating by Janus membranes with heterogeneous wetting properties for selective oil-water separation. ACS Appl Mater Interfaces 9:19102–19113. https://doi.org/10.1021/acsami.7b03313

Gupta P, Lapalikar V, Kundu R, Balasubramanian K (2016) Recent advances in membrane based waste water treatment technology: a review. Energy Environ Focus 5:241–267. https://doi.org/10.1166/eef.2016.1227

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392

Hwa LC, Uday MB, Ahmad N et al (2018) Integration and fabrication of the cheap ceramic membrane through 3D printing technology. Mater Today Commun 15:134–142. https://doi.org/10.1016/j.mtcomm.2018.02.029

Hyde J, MacNicol M, Odle A, Garcia-Rill E (2014) The use of three-dimensional printing to produce in vitro slice chambers. J Neurosci Methods 238:82–87. https://doi.org/10.1016/j.jneumeth.2014.09.012

Ivanova O, Williams C, Campbell T (2013) Additive manufacturing (AM) and nanotechnology: promises and challenges. Rapid Prototyp J 19:353–364. https://doi.org/10.1108/RPJ-12-2011-0127

Kalathil A, Raghavan A, Kandasubramanian B (2019) Polymer fuel cell based on polybenzimidazole membrane: a review. Polym Technol Mater 58:465–497. https://doi.org/10.1080/03602559.2018.1482919

Kelly BC, Ikonomou MG, Blair JD et al (2007) Food web-specific biomagnification of persistent organic pollutants. Science (80- ) 317:236–239. https://doi.org/10.1126/science.1138275

Khanale M, Balasubramanian K (2016) Molecular simulation of geometrically optimized polyoxymethylene/poly (vinylalcohol) gel membrane for electroless scrubbing Ni(II) ions. J Environ Chem Eng 4:434–439. https://doi.org/10.1016/j.jece.2015.11.044

Kok YH, Tan XP, Loh NH et al (2016) Geometry dependence of microstructure and microhardness for selective electron beam-melted Ti–6Al–4V parts. Virtual Phys Prototyp 11:183–191. https://doi.org/10.1080/17452759.2016.1210483

Korde JM, Balasubramanian K (2019) Naturally biomimicked smart shape memory hydrogels for biomedical functions. Chem Eng J:122430. https://doi.org/10.1016/j.cej.2019.122430

Korde JM, Shaikh M, Kandasubramanian B (2018) Bionic prototyping of honeycomb patterned polymer composite and its engineering application. Polym-Plast Technol Eng:1–17. https://doi.org/10.1080/03602559.2018.1434667

Krishna MVB, Chandrasekaran K, Karunasagar D, Arunachalam J (2001) A combined treatment approach using Fenton’s reagent and zero valent iron for the removal of arsenic from drinking water. J Hazard Mater 84:229–240. https://doi.org/10.1016/S0304-3894(01)00205-9

Kruth J-P, Leu MC, Nakagawa T (1998) Progress in additive manufacturing and rapid prototyping. CIRP Ann 47:525–540. https://doi.org/10.1016/S0007-8506(07)63240-5

Kruth JP, Froyen L, Van Vaerenbergh J et al (2004) Selective laser melting of iron-based powder. J Mater Process Technol 149:616–622. https://doi.org/10.1016/j.jmatprotec.2003.11.051

Kruth J, Mercelis P, Van Vaerenbergh J et al (2005) Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp J 11:26–36. https://doi.org/10.1108/13552540510573365

Lee J-Y, An J, Chua CK, et al (2016a) A perspective on 3D printed membrane: direct/indirect fabrication methods via direct laser writing

Lee J-Y, Tan WS, An J et al (2016b) The potential to enhance membrane module design with 3D printing technology. J Membr Sci 499:480–490. https://doi.org/10.1016/j.memsci.2015.11.008

Lee J-Y, An J, Chua CK (2017) Fundamentals and applications of 3D printing for novel materials. Appl Mater Today 7:120–133. https://doi.org/10.1016/j.apmt.2017.02.004

Levy GN, Schindel R, Kruth JP (2003) Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann 52:589–609. https://doi.org/10.1016/S0007-8506(07)60206-6

Louvis E, Fox P, Sutcliffe CJ (2011) Selective laser melting of aluminium components. J Mater Process Technol 211:275–284. https://doi.org/10.1016/j.jmatprotec.2010.09.019

Low Z-X, Chua YT, Ray BM et al (2017) Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J Membr Sci 523:596–613. https://doi.org/10.1016/j.memsci.2016.10.006

Lv J, Gong Z, He Z et al (2017) 3D printing of a mechanically durable superhydrophobic porous membrane for oil–water separation. J Mater Chem A 5:12435–12444. https://doi.org/10.1039/C7TA02202F

Majouli A, Younssi SA, Tahiri S et al (2011) Characterization of flat membrane support elaborated from local Moroccan Perlite. Desalination 277:61–66. https://doi.org/10.1016/j.desal.2011.04.003

Malik A, Kandasubramanian B (2018) Flexible polymeric substrates for electronic applications. Polym Rev 58:630–667. https://doi.org/10.1080/15583724.2018.1473424

Mandal B (2002) Arsenic round the world: a review. Talanta 58:201–235. https://doi.org/10.1016/S0039-9140(02)00268-0

Mazinani S, Al-Shimmery A, Chew YMJ, Mattia D (2019) 3D printed fouling-resistant composite membranes. ACS Appl Mater Interfaces 11:26373–26383. https://doi.org/10.1021/acsami.9b07764

Mazumder S, Cole JV (2003) Rigorous 3-D mathematical modeling of PEM fuel cells. J Electrochem Soc 150:A1510. https://doi.org/10.1149/1.1615609

Melenka GW, Cheung BKO, Schofield JS, Dawson MR, Carey JP (2016) Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos Struct 153:866–875. https://doi.org/10.1016/j.compstruct.2016.07.018

Mishra N, Kandasubramanian B (2018) Biomimetic design of artificial materials inspired by iridescent nacre structure and its growth mechanism. Polym-Plast Technol Eng 57:1592–1606. https://doi.org/10.1080/03602559.2017.1326139

Mohanraj G, Mao C, Armine A et al (2018) Ink-jet printing-assisted modification on polyethersulfone membranes using a UV-reactive antimicrobial peptide for fouling-resistant surfaces. ACS Omega 3:8752–8759. https://doi.org/10.1021/acsomega.8b00916

Mousavi S, Deuber F, Petrozzi S et al (2018) Efficient dye adsorption by highly porous nanofiber aerogels. Colloids Surfaces A Physicochem Eng Asp 547:117–125. https://doi.org/10.1016/j.colsurfa.2018.03.052

Ngo TD, Kashani A, Imbalzano G et al (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Oliveira H (2012) Chromium as an environmental pollutant: insights on induced plant toxicity. Aust J Bot 2012:1–8. https://doi.org/10.1155/2012/375843

Patrick L (2002) Mercury toxicity and antioxidants: Part 1: role of glutathione and alpha-lipoic acid in the treatment of mercury toxicity. Altern Med Rev 7:456–471

Prasad A, Kandasubramanian B (2019) Fused deposition processing polycaprolactone of composites for biomedical applications. Polym Technol Mater 58:1365–1398. https://doi.org/10.1080/25740881.2018.1563117

Rajhans A, Gore PM, Siddique SK, Kandasubramanian B (2019) Ion-imprinted nanofibers of PVDF/1-butyl-3-methylimidazolium tetrafluoroborate for dynamic recovery of europium (III) ions from mimicked effluent. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2019.103068

Rasal RM, Janorkar AV, Hirt DE (2010) Poly(lactic acid) modifications. Prog Polym Sci 35:338–356. https://doi.org/10.1016/j.progpolymsci.2009.12.003

Rastogi P, Kandasubramanian B (2019a) Breakthrough in the printing tactics for stimuli-responsive materials: 4D printing. Chem Eng J 366:264–304. https://doi.org/10.1016/j.cej.2019.02.085

Rastogi P, Kandasubramanian B (2019b) Review of alginate-based hydrogel bioprinting for application in tissue engineering. Biofabrication 11:042001. https://doi.org/10.1088/1758-5090/ab331e

Rastogi S, Kandasubramanian B (2019c) Progressive trends in heavy metal ions and dyes adsorption using silk fibroin composites. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-019-07280-7

Rastogi P, Njuguna J, Kandasubramanian B (2019) Exploration of elastomeric and polymeric liquid crystals with photothermal actuation: a review. Eur Polym J 121:109287. https://doi.org/10.1016/j.eurpolymj.2019.109287

Saini S, Kandasubramanian B (2018) Engineered smart textiles and Janus microparticles for diverse functional industrial applications. Polym-Plast Technol Eng:1–17. https://doi.org/10.1080/03602559.2018.1466177

Sharma S, Balasubramanian K, Arora R (2016) Adsorption of arsenic (V) ions onto cellulosic-ferric oxide system: kinetics and isotherm studies. Desalin Water Treat 57:9420–9436. https://doi.org/10.1080/19443994.2015.1042066

Shirazi SFS, Gharehkhani S, Mehrali M et al (2015) A review on powder-based additive manufacturing for tissue engineering: selective laser sintering and inkjet 3D printing. Sci Technol Adv Mater 16:033502. https://doi.org/10.1088/1468-6996/16/3/033502

Shukla AK, Alam J, Alhoshan M et al (2018) Removal of heavy metal ions using a carboxylated graphene oxide-incorporated polyphenylsulfone nanofiltration membrane. Environ Sci Water Res Technol 4:438–448. https://doi.org/10.1039/C7EW00506G

Shukla AK, Alam J, Ansari MA et al (2019) Selective ion removal and antibacterial activity of silver-doped multi-walled carbon nanotube/polyphenylsulfone nanocomposite membranes. Mater Chem Phys 233:102–112. https://doi.org/10.1016/j.matchemphys.2019.05.054

Singh N, Kumar D, Sahu AP (2007) Arsenic in the environment: effects on human health and possible prevention. J Environ Biol 28:359–365

Singh R, Gautam N, Mishra A, Gupta R (2011) Heavy metals and living systems: an overview. Indian J Pharm 43:246. https://doi.org/10.4103/0253-7613.81505

Tan C, Zhou K, Ma W et al (2018) Selective laser melting of high-performance pure tungsten: parameter design, densification behavior and mechanical properties. Sci Technol Adv Mater 19:370–380. https://doi.org/10.1080/14686996.2018.1455154

Tatem HE, Cox BA, Anderson JW (1978) The toxicity of oils and petroleum hydrocarbons to estuarine crustaceans. Estuar Coast Mar Sci 6:365–373. https://doi.org/10.1016/0302-3524(78)90128-7

Tijing LD, Dizon JRC, Ibrahim I et al (2020) 3D printing for membrane separation, desalination and water treatment. Appl Mater Today 18:100486. https://doi.org/10.1016/j.apmt.2019.100486

Verma V, Balasubramanian K (2014) Experimental and theoretical investigations of Lantana camara oil diffusion from polyacrylonitrile membrane for pulsatile drug delivery system. Mater Sci Eng C 41:292–300. https://doi.org/10.1016/j.msec.2014.04.061

Vrouwenvelder JS, Graf von der Schulenburg DA, Kruithof JC et al (2009) Biofouling of spiral-wound nanofiltration and reverse osmosis membranes: a feed spacer problem. Water Res 43:583–594. https://doi.org/10.1016/j.watres.2008.11.019

Withell A, Diegel O, Grupp I et al (2011) Porous ceramic filters through 3D printing. In: Innovative developments in virtual and physical prototyping. CRC Press, pp 313–318

Wong KV, Hernandez A (2012) A review of additive manufacturing. ISRN Mech Eng 2012:1–10. https://doi.org/10.5402/2012/208760

Xing R, Huang R, Qi W et al (2018) Three-dimensionally printed bioinspired superhydrophobic PLA membrane for oil-water separation. AICHE J 64:3700–3708. https://doi.org/10.1002/aic.16347

Yadav R, Naebe M, Wang X, Kandasubramanian B (2017) Review on 3D Prototyping of Damage Tolerant Interdigitating Brick Arrays of Nacre. Ind Eng Chem Res

Yadav R, Goud R, Dutta A et al (2018) Biomimicking of hierarchal molluscan shell structure via layer by layer 3D printing. Ind Eng Chem Res 57:10832–10840. https://doi.org/10.1021/acs.iecr.8b01738

Yap CY, Chua CK, Dong ZL et al (2015) Review of selective laser melting: Materials and applications. Appl Phys Rev 2:041101. https://doi.org/10.1063/1.4935926

Yap CY, Chua CK, Dong ZL (2016) An effective analytical model of selective laser melting. Virtual Phys Prototyp 11:21–26. https://doi.org/10.1080/17452759.2015.1133217

Yap YL, Wang C, Sing SL et al (2017) Material jetting additive manufacturing: an experimental study using designed metrological benchmarks. Precis Eng 50:275–285. https://doi.org/10.1016/j.precisioneng.2017.05.015

Yuan S, Wang J, Wang X et al (2015) Poly(arylene sulfide sulfone) hybrid ultrafiltration membrane with TiO2-g-PAA nanoparticles: preparation and antifouling performance. Polym Eng Sci 55:2829–2837. https://doi.org/10.1002/pen.24174

Yuan S, Strobbe D, Kruth J-P et al (2017a) Production of polyamide-12 membranes for microfiltration through selective laser sintering. J Membr Sci 525:157–162. https://doi.org/10.1016/j.memsci.2016.10.041

Yuan S, Strobbe D, Kruth J-P et al (2017b) Super-hydrophobic 3D printed polysulfone membranes with a switchable wettability by self-assembled candle soot for efficient gravity-driven oil/water separation. J Mater Chem A 5:25401–25409. https://doi.org/10.1039/C7TA08836A

Yuan S, Zhu J, Li Y et al (2019) Structure architecture of micro/nanoscale ZIF-L on a 3D printed membrane for a superhydrophobic and underwater superoleophobic surface. J Mater Chem A 7:2723–2729. https://doi.org/10.1039/C8TA10249J

Zhakeyev A, Wang P, Zhang L et al (2017) Additive manufacturing: unlocking the evolution of energy materials. Adv Sci 4:1700187. https://doi.org/10.1002/advs.201700187

Acknowledgments

The authors are thankful to Dr. C. P. Ramanarayanan, Vice-Chancellor of DIAT (DU), Pune for the motivation and support. The first author would like to acknowledge Dr. B. Srinivasulu, Principal Director and Head, CIPET: Institute of Plastic Technology (IPT), Kochi, for the support. The authors are thankful to Mr. Raviprakash Magisetty, Mr. Prakash M. Gore, Mr. Swaroop Gharde, and Ms. Alsha Subash for their persistent technical support throughout the review writing. The authors are thankful to all anonymous reviewers and the Editor for improving the quality of the revised manuscript by their valuable suggestions and comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Issac, M.N., Kandasubramanian, B. Review of manufacturing three-dimensional-printed membranes for water treatment. Environ Sci Pollut Res 27, 36091–36108 (2020). https://doi.org/10.1007/s11356-020-09452-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09452-2