Abstract

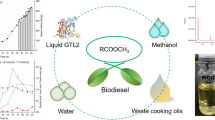

Recently, the research on conversion of biodiesel by-products to high value-added products has received much attention, due to the adverse effects of large accumulations of biodiesel by-products caused by the rapid increase in biodiesel production. Herein, this study investigated the utilization of by-products crude glycerol (CG-1 and CG-2) from two different industrial methods of biodiesel production and the favorable fermentation conditions for the high yield of β-farnesene by an engineered Escherichia coli F4, which harbored an optimized mevalonate pathway. Through analyzing by-products’ components and fermentation performance, we found that CG-2 did not contain harmful impurities such as methanol and black solid impurities, and the β-farnesene production was up to 2.7 g/L from CG-2, which was similar to that from pure glycerol (2.5 g/L) and higher than that (2.21 g/L) from CG-1. Therefore, CG-2 was more suitable for β-farnesene production than CG-1, which might provide a reference for choosing a more suitable method on practical biodiesel production. Afterward, a variety of important fermentation conditions were explored using CG-2 as a substrate in shaken flasks. Under the optimal conditions (including induced cell density 1.0, initial cell density 0.25, temperature after induction 33 °C, initial medium pH 6.5), the yield of β-farnesene from CG-2 reached 10.31 g/L in a 5-L bioreactor, which was 2.8-fold higher than initial conditions in shake flasks and was the highest yield of β-farnesene produced from biodiesel by-products by fermentation as well. The recommended fermentation conditions in this work will provide a valuable reference for the industrial production of β-farnesene utilizing biodiesel by-products.

Similar content being viewed by others

References

Ajikumar PK, Tyo K, Carlsen S, Mucha O, Phon TH, Stephanopoulos GJ (2008) Terpenoids: opportunities for biosynthesis of natural product drugs using engineered microorganisms. Mol Pharm 5:167–190

Anand P, Saxena RK (2012) A comparative study of solvent-assisted pretreatment of biodiesel derived crude glycerol on growth and 1, 3-propanediol production from Citrobacter freundii. New Biotechnol 29:199–205

Anastácio G, Santos K, Suarez P, Torres F, De Marco J, Parachin N (2014) Utilization of glycerin byproduct derived from soybean oil biodiesel as a carbon source for heterologous protein production in Pichia pastoris. Bioresour Technol 152:505–510

Anitha M, Kamarudin SK, Kofli NT (2016) The potential of glycerol as a value-added commodity. Chem Eng J 295:119–130

Ardi MS, Aroua MK, Hashim NA (2015) Progress, prospect and challenges in glycerol purification process: a review. Renew Sust Energ Rev 42:1164–1173

Baumann NA, Hagen P, Goldfine H (1965) Phospholipids of Clostridium butyricum studies on plasmalogen composition and biosynthesis. J Biol Chem 240:1559–1567

Behera AR, Veluppal A, Dutta K (2019) Optimization of physical parameters for enhanced production of lipase from Staphylococcus hominis using response surface methodology. Environ Sci Pollut Res 26:34277–34284

Chatzifragkou A, Papanikolaou S, Kopsahelis N, Kachrimanidou V, Dorado MP, Koutinas AA (2014) Biorefinery development through utilization of biodiesel industry by-products as sole fermentation feedstock for 1,3-propanediol production. Bioresour Technol 159:167–175

Chen C, Sun N, Li D, Long S, Tang X, Xiao G, Wang L (2018) Optimization and characterization of biosurfactant production from kitchen waste oil using Pseudomonas aeruginosa. Environ Sci Pollut Res 25:14934–14943

Duarte SH, de Andrade CC, Ghiselli G, Maugeri F (2013) Exploration of Brazilian biodiversity and selection of a new oleaginous yeast strain cultivated in raw glycerol. Bioresour Technol 138:377–381

Galafassi S, Cucchetti D, Pizza F, Franzosi G, Bianchi D, Compagno C (2012) Lipid production for second generation biodiesel by the oleaginous yeast Rhodotorula graminis. Bioresour Technol 111:398–403

Ganesh M, Senthamarai A, Shanmughapriya S, Natarajaseenivasan K (2015) Effective production of low crystallinity poly(3-hydroxybutyrate) by recombinant E. coli strain JM109 using crude glycerol as sole carbon source. Bioresour Technol 192:677–681

Gardner TS, Hawkins KM, Meadows AL, Tsong AE, Tsegaye Y (2014) Production of acetyl-coenzyme a derived isoprenoids. Google Patents

Givskov M, Eberl L, Christiansen G, Benedik MJ, Molin S (1995) Induction of phospholipase-and flagellar synthesis in Serratia liquefaciens is controlled by expression of the flagellar master operon flhD. Mol Microbiol 15:445–454

Han JY, Song JM, Seo SH, Wang C, Lee SG, Lee H, Kim SW, Choi ES (2018) Ty1-fused protein-body formation for spatial organization of metabolic pathways in Saccharomyces cerevisiae. Biotechnol Bioeng 115:694–704

Haron R, Mat R, Abdullah TAT, Rahman RA (2018) Overview on utilization of biodiesel by-product for biohydrogen production. J Clean Prod 172:314–324

Hommeltoft SI (2017) Farnesane alkylation. US

Huang Y, Li Z, Shimizu K, Ye Q (2012) Simultaneous production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol by a recombinant strain of Klebsiella pneumoniae. Bioresour Technol 103:351–359

Huang D, Wang R, Du W, Wang G, Xia M (2015) Activation of glycerol metabolic pathway by evolutionary engineering of Rhizopus oryzae to strengthen the fumaric acid biosynthesis from crude glycerol. Bioresour Technol 196:263–272

Jodhka U, Shepard C, Bradee A, Bryant R (2007) Production of PHB from crude glycerol. Eng Life Sci 7:475–479

Leavell MD, Mcphee DJ, Paddon CJ (2016) Developing fermentative terpenoid production for commercial usage. Curr Opin in Biotechnology 37:114–119

Liu Y (2011) Bioconversion of crude glycerol to glycolipids in Ustilago maydis. Bioresour Technol 102:3927–3933

Liu X, Jensen PR, Workman MJ (2012) Bioconversion of crude glycerol feedstocks into ethanol by Pachysolen tannophilus. Bioresour Technol 104:579–586

Lv J, Wang Y, Zhang C, You S, Qi W, Su R, He Z (2019) Highly efficient production of FAMEs and β-farnesene from a two-stage biotransformation of waste cooking oils. Energ Convers and Manage 199:112001

Maina S, Kachrimanidou V, Ladakis D, Papanikolaou S, de Castro AM, Koutinas A (2019) Evaluation of 1, 3-propanediol production by two Citrobacter freundiistrains using crude glycerol and soybean cake hydrolysate. Environ Sci Pollut Res 26:1–10

Marchetti J, Miguel V, Errazu A (2007) Possible methods for biodiesel production. Renew Sust Energ Rev 11:1300–1311

Marchetti JM, Miguel VU, Errazu AF (2008) Techno-economic study of different alternatives for biodiesel production. Fuel Process Technol 89:740–748

Martin VJ, Pitera DJ, Withers ST, Newman JD, Keasling JD (2003) Engineering a mevalonate pathway in Escherichia coli for production of terpenoids. Nat Biotechnol 21:796–802

McCoy M (2006) Glycerin surplus. AMER CHEMICAL SOC 1155 16TH ST, NW, WASHINGTON, DC 20036 USA

Millo F, Bensaid S, Fino D, Marcano SJC, Vlachos T, Debnath BK (2014) Influence on the performance and emissions of an automotive Euro 5 diesel engine fueled with F30 from Farnesane. Fuel 138:134–142

Nawaz MA, Bibi Z, Karim A, Rehman HU, Jamal M, Jan T, Aman A, Qader SAU (2017) Production of α-1, 4-glucosidase from Bacillus licheniformis KIBGE-IB4 by utilizing sweet potato peel. Environ Sci Pollut Res 24:4058–4066

Oh PP, Lau HLN, Chen J, Chong MF, Choo YM (2012) A review on conventional technologies and emerging process intensification (PI) methods for biodiesel production. Renew Sust Energ Rev 16:5131–5145

Okoye PU, Abdullah AZ, Hameed BH (2017) A review on recent developments and progress in the kinetics and deactivation of catalytic acetylation of glycerol—a byproduct of biodiesel. Renew Sust Energ Rev 74:387–401

Pechous SW, Whitaker BD (2004) Cloning and functional expression of an (E, E)-α-farnesene synthase cDNA from peel tissue of apple fruit. Planta 219:84–94

Picaud S, Brodelius M, Brodelius PE (2005) Expression, purification and characterization of recombinant (E)-β-farnesene synthase from Artemisia annua. Phytochemistry 66:961–967

Pott RW, Howe CJ, Dennis JS (2014) The purification of crude glycerol derived from biodiesel manufacture and its use as a substrate by Rhodopseudomonas palustris to produce hydrogen. Bioresour Technol 152C:464–470

Praveen N, Murthy H (2012) Synthesis of withanolide A depends on carbon source and medium pH in hairy root cultures of Withania somnifera. Ind Crop Prod 35:241–243

Pyle DJ, Garcia RA, Zhiyou W (2008) Producing docosahexaenoic acid (DHA)-rich algae from biodiesel-derived crude glycerol: effects of impurities on DHA production and algal biomass composition. J Agr Food Chem 56:3933–3939

Renninger N S MDJ (2010) Fuel compositions comprising farnesane and farnesane derivatives and method of making and using same. WO

Rodzri N, Zain W, Hanapiah R, Samah R, Illias R (2019) Effect of physical parameters on production of D-Xylonic acid using recombinant E. coli BL21 (DE3). Materials Today: Proceedings 19:1247–1254

Sekar A, Shin Y, Jeong H, Kim K (2018) Statistical optimization of culture medium to produce recombinant viral protein by Escherichia coli host for diagnostic kit to detect human immunodeficiency virus (HIV) infection. Biochem Bioph Res Co 504:666–671

Stefan T, Yun C, Verena S, Jens NJ (2013) From flavors and pharmaceuticals to advanced biofuels: production of isoprenoids in Saccharomyces cerevisiae. Biotechnol J 8:1435–1444

Suman M, Clomburg JM, Ramon G (2010) Escherichia coli strains engineered for homofermentative production of D-lactic acid from glycerol. Appl Environ Microb 76:4327–4336

Tippmann S, Chen Y, Siewers V, Nielsen J (2013) From flavors and pharmaceuticals to advanced biofuels: production of isoprenoids in Saccharomyces cerevisiae. Biotechnol J 8:1435–1444

Tippmann S, Scalcinati G, Siewers V, Nielsen J (2016) Production of farnesene and santalene by Saccharomyces cerevisiae using fed-batch cultivations with RQ-controlled feed. Biotechnol Bioeng 113:72–81

Venkataramanan KP, Boatman JJ, Kurniawan Y, Taconi KA, Bothun GD, Scholz C (2012) Impact of impurities in biodiesel-derived crude glycerol on the fermentation by Clostridium pasteurianum ATCC 6013. Appl Microbiol Biot 93:1325–1335

Vickers CE, Williams TC, Peng B, Cherry J (2017) Recent advances in synthetic biology for engineering isoprenoid production in yeast. Curr Opin Chem Biol 40:47–56

Wang C-T, Chen W-J, Huang R-Y (2010) Influence of growth curve phase on electricity performance of microbial fuel cell by Escherichia coli. Int J Hydrogen Energ 35:7217–7223

Wang C, Yoon SH, Jang HJ, Chung YR, Kim JY, Choi ES, Kim SW (2011) Metabolic engineering of Escherichia coli for alpha-farnesene production. Metab Eng 13:648–655

Won Jae C, Maria Regina H, Heng CW, Suan Siong Y (2011) Ethanol production from biodiesel-derived crude glycerol by newly isolated Kluyvera cryocrescens. Appl Microbiol Biot 89:1255–1264

Yang F, Hanna MA, Sun R (2012) Value-added uses for crude glycerol--a byproduct of biodiesel production. Biotechnol Biofuels 5:13

Yang X, Nambou K, Wei L, Hua QJ (2016) Heterologous production of α-farnesene in metabolically engineered strains of Yarrowia lipolytica. Bioresour Technol 216:1040–1048

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18:213–219

Yee L, Blanch H (1993) Recombinant trypsin production in high cell density fed-batch cultures in Escherichia coli. Biotechnol Bioeng 41:781–790

You S, Yin Q, Zhang J, Zhang C, Qi W, Gao L, Tao Z, Su R, He Z (2017a) Utilization of biodiesel by-product as substrate for high-production of β-farnesene via relatively balanced mevalonate pathway in Escherichia coli. Bioresour Technol 243:228–236

You S, Zhang J, Yin Q, Qi W, Su R, He Z (2017b) Development of a novel integrated process for co-production of β-galactosidase and ethanol using lactose as substrate. Bioresour Technol 230:15–23

Zebec Z, Wilkes J, Jervis AJ, Scrutton NS, Takano E, Breitling R (2016) Towards synthesis of monoterpenes and derivatives using synthetic biology. Curr Opin Chem Biol 34:37–43

Zhu F, Zhong X, Hu M, Lu L, Deng Z, Liu T (2014) In vitro reconstitution of mevalonate pathway and targeted engineering of farnesene overproduction in Escherichia coli. Biotechnol Bioeng 111:1396–1405

Funding

This study received financial support from the Science Fund for Creative Research Groups (No. 21621004), the Project funded by China Postdoctoral Science Foundation (No. 2019M651040), the Key Project of Science and Technology Committee of Tianjin (No. 17YFZCSY01080), the Tianjin Development Program for Innovation and Entrepreneurship (2018), and the Beiyang Young Scholar of Tianjin University (2012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 337 kb)

Rights and permissions

About this article

Cite this article

Yao, P., You, S., Qi, W. et al. Investigation of fermentation conditions of biodiesel by-products for high production of β-farnesene by an engineered Escherichia coli. Environ Sci Pollut Res 27, 22758–22769 (2020). https://doi.org/10.1007/s11356-020-08893-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08893-z