Abstract

The spent biological activated carbon (BAC) should be disposed properly; regeneration was a better choice. Performances of thermal and ultrasonic regeneration to the BAC with various service time (3 years, 5 years, and 10 years) were compared comprehensively; the recovery of the BAC’s pore structure, variation of mechanical hardness, influence of bioactivity, and removal efficiency of typical pollutants in the reuse were examined. The results showed that thermal regeneration was an utterly regeneration, and almost all the pore structure was restored, whose recovery rate was above 90% for BAC used 3 years and disfavored by the longer BAC’s service time (83% for the BAC used 5 years). Ultrasonic regeneration could recover part of the BAC’s pores (including micropores) and the restoration mainly focused on the BAC’s surface, so the recovery rate was not influenced by the BAC’s service time, and the recovery values of specific surface areas and iodine value were kept at 120 m2/g and 200 mg/g, respectively. In addition, the ultrasonic treatment enhanced the BAC’s biological activity even with a significant decrease of the biomass on the BAC. The mechanical hardness of BAC decreased from 95 to 89% for the first regeneration and further to 79% for the second regeneration, whereas relatively lower decrease happened for the ultrasonic regeneration (less than 10% after 5 regeneration cycles). The mass losses in the thermal and ultrasonic regeneration were about 13%, 0.5%, and 25%, 3% for the first and second regeneration, respectively. The thermal-regenerated activated carbon (AC) exhibited excellent adsorption ability, good adherence of biofilm, and maintain higher removal rate for more than 2 years, which were similar with that of the fresh AC, but relatively lower removal performance was found. However, the ultrasonic regenerated BAC retained the biodegradation ability, restored the fast-adsorption ability, and the higher removal process lasted about 6 months. Taking the regeneration cost, operation, variation of the AC’s characteristics, and the removal performance in reuse, ultrasonic regeneration was more suitable for the BAC filter and better used as a regular measure to maintain the higher removal performance, whereas thermal regeneration was more applicable to the activated carbon adsorption tank.

Similar content being viewed by others

References

Andersson A, Laurent P, Kihn A, Prévost M, Servais P (2001) Impact of temperature on nitrification in biological activated carbon (BAC) filters used for drinking water treatment. Water Research 35:2923–2934

Bagreev A, Rahman H, Bandosz TJ (2001) Thermal regeneration of a spent activated carbon previously used as hydrogen sulfide adsorbent. Carbon 39:1319–1326

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I Computations from Nitrogen. Journal of America Chemistry Society 73:373–380

Barton S, Bullock C, Weir D (1996) The effects of ultrasound on the activities of some glycosidase enzymes of industrial importance. Enzym Microb Technol 18:190–194

Berenguer R, Marcolozar JP, Quijada C, Cazorla-Amoros D, Morallon E (2010) Electrochemical regeneration and porosity recovery of phenol-saturated granular activated carbon in an alkaline medium. Carbon 48:2734–2745

Bozena SS, Maria T, Magdalena J, Morawski AW (2006) Biological activation of carbon filters. Water Res 40:355–363

Chen F, Peldszus S, Elhadidy AM, Legge RL, Dyke MIV, Huck PM (2016) Kinetics of natural organic matter (NOM) removal during drinking water biofiltration using different NOM characterization approaches. Water Res 104:361–370

Chin A, Bérubé PR (2005) Removal of disinfection by-product precursors with ozone-UV advanced oxidation process. Water Res 39:2136–2144

Cooney DO, Nagerl R, Hines AL (1983) Solvent regeneration of activated carbon. Water Res 17:403–410

Gang L, Ben W, Hui Y, Dong Z, Qiang Z (2018) Performance of ozonation and biological activated carbon in eliminating sulfonamides and sulfonamide-resistant bacteria: a pilot-scale study. Chemical Engineering Journal:S1385894718302298

GARCÍA-OTÓN M, Montilla F, LILLO-RÓDENAS MA, Morallón E, Vázquez JL (2005) Electrochemical regeneration of activated carbon saturated with toluene. J Appl Electrochem 35:319–325

Gibert O, Lefèvre B, Fernández M, Bernat X, Paraira M, Calderer M, Martínez-Lladó X (2013) Characterising biofilm development on granular activated carbon used for drinking water production. Water Res 47:1101–1110

Hamdaoui O, Naffrechoux E, Suptil J, Fachinger C (2005) Ultrasonic desorption of p -chlorophenol from granular activated carbon. Chem Eng J 106:153–161

Hameed BH, Chin LH, Rengaraj S (2008) Adsorption of 4-chlorophenol onto activated carbon prepared from rattan sawdust. Desalination 225:185–198

Jae-Lim L, Mitsumasa O (2005) Regeneration of granular activated carbon using ultrasound. Ultrason Sonochem 12:277–282

Jie Z, Shen L, Hui Z, Ye C, Weng L (2008) Practical application of reactivated granule activated carbon in Guoyuanqiao Waterworks. Water & Wastewater Engineering

Klausen MM, Grønborg O (2010) Pilot scale testing of advanced oxidation processes for degradation of geosmin and MIB in recirculated aquaculture. Water Sci Technol Water Supply 10:217

Korotta-Gamage SM, Sathasivan A (2017) A review: potential and challenges of biologically activated carbon to remove natural organic matter in drinking water purification process. Chemosphere 167:120–138

Liu C, Wang J, Cao Z, Chen W, Bi H (2016) Variation of dissolved organic nitrogen concentration during the ultrasonic pretreatment to Microsystis aeruginosa. Ultrasonics Sonochemistry

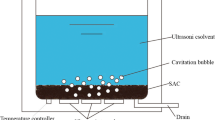

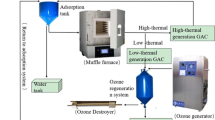

Liu C, Sun Y, Wang D, Sun Z, Chen M, Zhou Z, Chen W (2017) Performance and mechanism of low-frequency ultrasound to regenerate the biological activated carbon. Ultrason Sonochem 34:142–153

Lorenc-Grabowska E, Rutkowski P (2014) High adsorption capacity carbons from biomass and synthetic polymers for the removal of organic compounds from water. Water Air Soil Pollut 225:1–10

Mazyck DW (2007) Reactivation of granular activated carbon, AWWA Stand, American Water Works Association

Miguel GS, Lambert SD, Graham NJD (2001) The regeneration of field-spent granular-activated carbons. Water Res 35:2740–2748

Narbaitz RM, Cen J (1994) Electrochemical regeneration of granular activated carbon. Water Res 28:1771–1778

Nemr AE, Abdelwahab O, El-Sikaily A, Khaled A (2009) Removal of direct blue-86 from aqueous solution by new activated carbon developed from orange peel. J Hazard Mater 161:102–110

Pitt WG, Ross SA (2010) Ultrasound increases the rate of bacterial cell growth. Biotechnol Prog 19:1038–1044

Popescu M, Joly JP, Carré J, Danatoiu C (2003) Dynamical adsorption and temperature-programmed desorption of VOCs (toluene, butyl acetate and butanol) on activated carbons. Carbon 41:739–748

Sabio E, Gonzalez E, Gonzalez JF, Gonzalez Garcia CM, Ramiro A (2004) Thermal regeneration of activated carbon saturated with p-nitrophenol. Carbon 42:2285–2293

Sakakibara M, Wang D, Takahashi R, Takahashi K, Mori S (1996) Influence of ultrasound irradiation on hydrolysis of sucrose catalyzed by invertase. Enzym Microb Technol 18:444–448

Shende RV, Mahajani VV (2002) Wet oxidative regeneration of activated carbon loaded with reactive dye. Waste Manag 22:73–83

Sun Z, Liu C, Cao Z, Chen W (2018) Study on regeneration effect and mechanism of high-frequency ultrasound on biological activated carbon. Ultrason Sonochem 44:86–96

Wenhai C, Naiyun G, Daqiang Y, Yang D, Templeton MR (2012) Ozone-biological activated carbon integrated treatment for removal of precursors of halogenated nitrogenous disinfection by-products. Chemosphere 86:1087–1091

Xia H et al (2015) Microwave assisted regeneration of spent activated carbon from petrochemical plant using response surface methodology. J Porous Mater 22:137–146

Zhang G, Wang S, Liu Z (2003) Ultrasonic regeneration of granular activated carbon. Environ Eng 20:1–3

Funding

This work was supported by the National Natural Science Foundation of China (51438006), and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

Ultrasonic and thermal regeneration to the BAC with different service time were compared comprehensively.

Thermal regeneration recovers the BAC’s pores entirely and longer service time disfavored the recovery.

Thermal regeneration deteriorates the hardness of the BAC dramatically and 2 regenerated times were limited.

Ultrasonic treatment recovers part of the BAC’s pores and mainly focus on the BAC’s surface.

The recovery value of the pore volume, specific surface area, and iodine is stable irrespective of service time.

Ultrasonic regeneration exhibits some advantages and is more suitable to the BAC’s regeneration.

Proper application mode for the two methods is suggested in view of the performance, cost, and application.

Rights and permissions

About this article

Cite this article

Liu, C., Li, C., Shan, Y. et al. Comparison of two typical regeneration methods to the spent biological activated carbon in drinking water. Environ Sci Pollut Res 27, 16404–16414 (2020). https://doi.org/10.1007/s11356-019-07440-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07440-9