Abstract

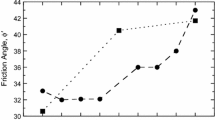

Crushed waste rocks can be used as materials for backfilling goafs, so as to achieve the simultaneous goals of processing solid waste and controlling surface subsidence; however, particle size distribution directly affects the compaction of crushed waste rocks. Therefore, by employing a self-designed bidirectional loading test system for granular materials, this study tested compaction characteristics of crushed waste rocks with four different particle size distributions. Moreover, this research tested the changes of parameters in lateral and axial loading of crushed waste rocks and analysed the influence of particle size distribution on lateral strain, axial strain, porosity, lateral stress, and lateral pressure coefficient during compaction. The test results show that (1) particle size distribution affects porosity, strain, and lateral pressure coefficient of crushed waste rocks under lateral and axial loading. (2) For the samples under particle size distribution ranging from 0 to 10 mm, the initial porosity is low and deformations are small under axial loading, so that particles can make contact and bear effective stress in grain-grain contact. Therefore, more stress is transferred to the lateral direction. (3) After compaction, the curves of the samples of crushed waste rocks under four particle size distributions all shift upwards in comparison with those before compaction, indicating that particles are crushed and the proportion of small particles constantly increases. (4) A reasonable particle size distribution can significantly improve stress characteristics, reduce crushing of particles in the samples, and increase the stiffness of the samples, so as to achieve better compaction effects.

Similar content being viewed by others

References

Aydan Ö, Ito T, Özbay U, Kwasniewski M, Shariar K, Okuno T, Özgenoğlu A, Malan DF, Okada T (2014) Isrm suggested methods for determining the creep characteristics of rock. Rock Mech Rock Eng 47(1):275–290

Chang QL, Tang WJ, Xu Y, Zhou HQ (2018) Research on the width of filling body in gob-side entry retaining with high-water materials. Int J Min Sci Technol 28:519–524

Daniel MF, David VB, Claire MC, David RM (2011) Sustainable development principles for the disposal of mining and mineral processing wastes. Res Policy 36:114–122

Evans DM, Zipper CE, Hester ET, Schoenholtz SH (2015) Hydrologic effects of surface coal mining in Appalachia (U.S.). Jawra J Am Water Resour Assoc 51(5):1436–1452

Fan GW, Zhang DS, Wang XF (2014) Reduction and utilization of coal mine waste rock in China: a case study in Tiefa coalfield. Resour Conserv Recycl 83(5):24–33

Günther RM, Salzer K, Popp T, Lüdeling C (2015) Steady-state creep of rock salt: improved approaches for lab determination and modelling. Rock Mech Rock Eng 48(6):2603–2613

Guo X, Zhang XX, Yue J, Zhu K (2018) A case study of the key factors and mechanism associated with mining site pollution control based on an e-platform management system. Int Biodeterior Biodegrad 128:177–181

Guo WB, Zhao GB, Lou GZ, Wang SR (2019) Height of fractured zone inside overlying strata under high-intensity mining in China. Int J Min Sci Technol 29:45–49

Huang YL, Zhang JX, Zhang Q, Nie SJ (2011) Backfilling technology of substituting waste and fly ash for coal underground in China coal mining area. Environ Eng Manag J 10:769–775

Karfakis MG, Bowman CH, Topuz E (1996) Characterization of coal-mine refuse as backfilling material. Geotech Geol Eng 14(2):129–150

Li M, Zhang JX, Huang P, Gao R (2016) Mass ratio design based on compaction properties of backfill materials. J Cent South Univ 23(10):2669–2675

Li M, Zhang JX, Deng XJ, Ju F, Li BY (2017a) Measurement and numerical analysis of water-conducting fractured zone in solid backfill mining under an aquifer: a case study in China. Q J Eng Geol Hydrogeol 50(1):81–87

Li M, Zhang JX, Zhou N, Huang YL (2017b) Effect of particle size on the energy evolution of crushed waste rock in coal mines. Rock Mech Rock Eng 50(5):1347–1354

Ma D, Bai HB, Miao XB, Pu H, Jiang BY, Chen ZQ (2016) Compaction and seepage properties of crushed limestone particle mixture: an experimental investigation for Ordovician karst collapse pillar groundwater inrush. Environ Earth Sci 75(1):1–14

National Energy Administration (2014) Method of compaction testing of solid backfilling materials. Energy industry standard, Beijing, NB/T 51019–2014

O’Sullivan C (2011) Particle-based discrete element modeling: geomechanics perspective. Int J Geomech 11(6):449–464

Pappas DM, Mark C (1993) Behavior of simulated longwall gob material. Report of investigations/1993. U.S. department of the Interior Bureau of Mines Ri, Pittsburgh

Park JW, Song JJ (2009) Numerical simulation of a direct shear test on a rock joint using a bonded-particle model. Int J Rock Mech Min 46(8):1315–1328

Roberts LA, Buchholz SA, Mellegard KD, Düsterloh U (2015) Cyclic loading effects on the creep and dilation of salt rock. Rock Mech Rock Eng 48(6):2581–2590

Sitharam TG, Vinod JS (2010) Evaluation of shear modulus and damping ratio of granular materials using discrete element approach. Geotech Geol Eng 28(5):591–601

Stewart BR, Daniels WL (1992) Physical and chemical properties of coal refuse from Southwest Virginia. J Environ Qual (United States) 21(4):635–642

Su CD, Gu M, Tang X, Guo W (2012) Experiment study of compaction characteristics of crushed stones from coal seam roof. Chin J Rock Mech Eng 31(1):2012–2011

Sun W, Wang HJ, Hou KP (2018) Control of waste rock-tailings paste backfill for active mining subsidence areas. J Clean Prod 171:567–579

Yuan L (2017) Scientific conception of precision coal mining. J China Coal Soc 42(1):1–7

Zhang ZN, Miao XX, Ge XR (2005) Testing study on compaction breakage of loose rock blocks. Chin J Rock Mech Eng 24(3):451–455

Zhang JX, Miao XX, Guo GL (2009) Development status of backfilling technology using raw waste in coal mining. J Min Safety Eng 26(4):395–401

Zhang Y, Li J, Cheng F, Guo Y (2015) Study of the combustion behavior and kinetics of different types of coal gangue. Combust Explos Shock Waves 51(6):670–677

Zhang JX, Li M, Liu Z, Zhou N (2016) Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol 305:12–18

Zhang JX, Zhang Q, Spearing AJS, Miao XX, Guo S, Sun Q (2017) Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int J Min Sci Technol 27:17–27

Zhao XT, Gao XC, Li DS (2012) The stability analysis of Nantong coal mine waste dump, Chongqing and prevention measures. Appl Mech Mater 204-208:3526–3531

Zhou N, Zhang J, Yan H, Li M (2017) Deformation behavior of hard roofs in solid backfill coal mining using physical models. Energies 10(4):1–20

Zhu XJ, Guo GL, Fang Q (2016) Coupled discrete element–finite difference method for analyzing subsidence control in fully mechanized solid backfilling mining. Environ Earth Sci 75(8):1–12

Funding

Financial support for this work was provided by the National Postdoctoral Program for Innovative Talents (BX20180361), the China Postdoctoral Science Foundation (2018M642366) and the National Science Fund for Distinguished Young Scholars (51725403).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Zhang, J., Song, W. et al. Recycling of crushed waste rock as backfilling material in coal mine: effects of particle size on compaction behaviours. Environ Sci Pollut Res 26, 8789–8797 (2019). https://doi.org/10.1007/s11356-019-04379-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-04379-9