Abstract

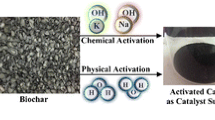

The feasibility of biomass-based activated carbons has received a huge attention due to their excellent characteristics such as inexpensiveness, good adsorption behaviour and potential to reduce a strong dependency towards non-renewable precursors. Therefore, in this research work, eco-friendly activated carbon from palm kernel shell that has been produced from one-stage physical activation by using the Box-Behnken design of Response Surface Methodology is highlighted. The effect of three input parameters—temperature, dwell time and gas flow rate—towards product yield and carbon dioxide (CO2) uptake at room temperature and atmospheric pressure are studied. Model accuracy has been evaluated through the ANOVA analysis and lack-of-fit test. Accordingly, the optimum condition in synthesising the activated carbon with adequate CO2 adsorption capacity of 2.13 mmol/g and product yield of 25.15 wt% is found at a temperature of 850 °C, holding time of 60 min and CO2 flow rate of 450 cm3/min. The synthesised activated carbon has been characterised by diverse analytical instruments including thermogravimetric analyser, scanning electron microscope, as well as N2 adsorption-desorption isotherm. The characterisation analysis indicates that the synthesised activated carbon has higher textural characteristics and porosity, together with better thermal stability and carbon content as compared to pristine palm kernel shell. Activated carbon production via one-step activation approach is economical since its carbon yield is within the industrial target, whereas CO2 uptake is comparable to the synthesised activated carbon from conventional dual-stage activation, commercial activated carbon and other published data from literature.

Similar content being viewed by others

References

Alam MZ, Ameem ES, Muyibi SA, Kabbashi NA (2009) The factors affecting the performance of activated carbon prepared from oil palm empty fruit bunches for adsorption of phenol. Chem Eng J 155:191–198

Álvarez-Gutiérrez N, Victoria Gil M, Rubiera F, Pevida C (2015) Cherry-stones-based activated carbons as potential adsorbents for CO2/CH4 separation: effect of the activation parameters. Greenhouse Gases: Sci Technol 5:812–825

Arami-Niya A, Daud WMAW, Mjalli FS, Abnisa F, Shafeeyan MS (2012) Production of microporous palm shell based activated carbon for methane adsorption: modeling and optimization using response surface methodology. Chem Eng Res Des 90:776–784

Asuquo E, Martin A, Nzerem P, Siperstein F, Fan X (2017) Adsorption of Cd (II) and Pb (II) ions from aqueous solutions using mesoporous activated carbon adsorbent: equilibrium, kinetics and characterisation studies. J Environ Chem Eng 5:679–698

Bachrun S, AyuRizka N, Annisa S, Arif H (2016) Preparation and characterization of activated carbon from sugarcane bagasse by physical activation with CO2 gas. IOP Conference Series: Mater Sci Eng 105:1–8

Bagheri S, Muhd Julkapli N, Bee Abd Hamid S (2015) Functionalized activated carbon derived from biomass for photocatalysis applications perspective. Int J Photoenergy 2015:1–30

Bakar AHBA et al (2016) Removal of fluoride using quaternized palm kernel shell as adsorbents: equilibrium isotherms and kinetics studies. Bioresources 11:4485–4511

Bakar DA, Anandarajah G (2015) Sustainability of bioenergy in Malaysia with reference to palm oil biomass: adopting principles governing bioenergy policy in the UK. WIT Trans Ecol Environ 206:57–67

Boey P-L, Maniam GP, Hamid SA (2009) Biodiesel production via transesterification of palm olein using waste mud crab (Scylla serrata) shell as a heterogeneous catalyst. Bioresour Technol 100:6362–6368

Calvo-Muñoz EM, García-Mateos FJ, Rosas JM, Rodríguez-Mirasol J, Cordero T (2016) Biomass waste carbon materials as adsorbents for CO2 capture under post-combustion conditions. Frontiers Materials 3:1–14

Chowdhury ZZ, Hamid SA, Rahman MM, Rafique RF (2016) Catalytic activation and application of micro-spherical carbon derived from hydrothermal carbonization of lignocellulosic biomass: statistical analysis using Box–Behnken design. RSC Adv 6:102680–102694

Czitrom V (1999) One-factor-at-a-time versus designed experiments. Am Stat 53:126–131

Danish M, Hashim R, Ibrahim MM, Sulaiman O (2014) Optimized preparation for large surface area activated carbon from date (Phoenix dactylifera L.) stone biomass. Biomass Bioenergy 61:167–178

Das S, Mishra S (2017) Box-Behnken statistical design to optimize preparation of activated carbon from Limonia acidissima shell with desirability approach. J Environ Chem Eng 5:588–600

De Gisi S, Lofrano G, Grassi M, Notarnicola M (2016) Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: a review. Sustain Mater Technol 9:10–40

Essa MH, Al-Zahrani MA, Nesaratnam S (2013) Optimisation of activated carbon production from date pits. Int J Environ Eng 5:325–338

Garg KK, Prasad B (2016) Development of Box Behnken design for treatment of terephthalic acid wastewater by electrocoagulation process: optimization of process and analysis of sludge. J Environ Chem Eng 4:178–190

González AS, Plaza MG, Rubiera F, Pevida C (2013) Sustainable biomass-based carbon adsorbents for post-combustion CO2 capture. Chem Eng J 230:456–465

Gurram RK, Gandra S, Shastri NR (2016) Design and optimization of disintegrating pellets of MCC by non-aqueous extrusion process using statistical tools. Eur J Pharm Sci 84:146–156

Hamza UD, Nasri NS, Amin NS, Mohammed J, Zain HM (2016) Characteristics of oil palm shell biochar and activated carbon prepared at different carbonization times. Desalin Water Treat 57:7999–8006

Hapazari I, Ntuli V, Parawira W (2011) Evaluation of single-step steam pyrolysis-activated carbons from Lesotho agro-forestry residues. Tanzania J Sci 37:120–128

Heo Y-J, Park S-J (2015) A role of steam activation on CO2 capture and separation of narrow microporous carbons produced from cellulose fibers. Energy 91:142–150

Huang K, Lu W, Guo J, Luo Y, Ye Q-z (2010) Mesoporous activated carbons derived from bamboo solid wastes: preparation, characterization and applications. In: 4th International Conference on Bioinformatics and Biomedical Engineering (iCBBE), IEEE, pp 1–2

Hui TS, Zaini MAA (2015) Potassium hydroxide activation of activated carbon: a commentary. Carbon Lett 16:275–280

Inam E, Etim U, Akpabio E, Umoren S (2017) Process optimization for the application of carbon from plantain peels in dye abstraction. J Taibah Univ Sci 11:173–185

Joglekar AM, May AT, Graf E, Saguy I (1987) Product excellence through design of experiments. Cereal Foods World 32:857–868

Kalderis D, Bethanis S, Paraskeva P, Diamadopoulos E (2008) Production of activated carbon from bagasse and rice husk by a single-stage chemical activation method at low retention times. Bioresour Technol 99:6809–6816

Karaman I, Yagmur E, Banford A, Aktas Z (2014) The effect of process parameters on the carbon dioxide based production of activated carbon from lignite in a rotary reactor. Fuel Process Technol 118:34–41

Katesa J, Junpiromand S, Tangsathitkulchai C (2013) Effect of carbonization temperature on properties of char and activated carbon from coconut shell. Suranaree. J Sci Technol 20:269–278

Khalili S, Khoshandam B, Jahanshahi M (2015) Optimization of production conditions for synthesis of chemically activated carbon produced from pine cone using response surface methodology for CO2 adsorption. RSC Adv 5:94115–94129

Kundu A, Redzwan G, Sahu JN, Mukherjee S, Gupta BS, Hashim MA (2014) Hexavalent chromium adsorption by a novel activated carbon prepared by microwave activation. Bioresources 9:1498–1518

Lai Z, Ma X, Tang Y, Lin H (2012) Thermogravimetric analysis of the thermal decomposition of MSW in N2, CO2 and CO2/N2 atmospheres. Fuel Process Technol 102:18–23

Liu L, Cao Y, Liu Q, Yang J (2017) Experimental and kinetic studies of coal–CO2 gasification in isothermal and pressurized conditions. RSC Adv 7:2193–2201

Mahmood T, Ali R, Naeem A, Hamayun M, Aslam M (2017) Potential of used Camellia sinensis leaves as precursor for activated carbon preparation by chemical activation with H3PO4; optimization using response surface methodology. Process Saf Environ Prot 109:548–563

Matos J, Nahas C, Rojas L, Rosales M (2011) Synthesis and characterization of activated carbon from sawdust of Algarroba wood. 1. Physical activation and pyrolysis. J Hazard Mater 196:360–369

Meng L, Park S (2012) Investigation of narrow pore size distribution on carbon dioxide capture of nanoporous carbons. Bull Korean Chem Soc 33:3749–3754

Nasri NS, Hamza UD, Ismail SN, Ahmed MM, Mohsin R (2014) Assessment of porous carbons derived from sustainable palm solid waste for carbon dioxide capture. J Clean Prod 71:148–157

Nizamuddin S, Shrestha S, Athar S, Ali BS, Siddiqui MA (2016) A critical analysis on palm kernel shell from oil palm industry as a feedstock for solid char production. Rev Chem Eng 32:489–505

Nor NM, Lau LC, Lee KT, Mohamed AR (2013) Synthesis of activated carbon from lignocellulosic biomass and its applications in air pollution control—a review. J Environ Chem Eng 1:658–666

Park Y, Lin K-YA, Park A-HA, Petit C (2015) Recent advances in anhydrous solvents for CO2 capture: ionic liquids, switchable solvents, and nanoparticle organic hybrid materials. Front Energy Res 3:1–14

Plaza MG, González AS, Pevida C, Pis JJ, Rubiera F (2012) Valorisation of spent coffee grounds as CO2 adsorbents for postcombustion capture applications. Appl Energy 99:272–279

Rafatullah M, Ahmad T, Ghazali A, Sulaiman O, Danish M, Hashim R (2013) Oil palm biomass as a precursor of activated carbons: a review. Crit Rev Environ Sci Technol 43:1117–1161

Rashidi NA, Yusup S, Borhan A (2016) Isotherm and thermodynamic analysis of carbon dioxide on activated carbon. Procedia Eng 148:630–637

Rashidi NA, Yusup S, Borhan A, Loong LH (2014) Experimental and modelling studies of carbon dioxide adsorption by porous biomass derived activated carbon. Clean Techn Environ Policy 16:1353–1361

Rashidi NA, Yusup S, Hameed BH (2013) Kinetic studies on carbon dioxide capture using lignocellulosic based activated carbon. Energy 61:440–446

Salman J (2014) Optimization of preparation conditions for activated carbon from palm oil fronds using response surface methodology on removal of pesticides from aqueous solution. Arab J Chem 7:101–108

Sanz-Pérez E, Arencibia A, Sanz R, Calleja G (2015) An investigation of the textural properties of mesostructured silica-based adsorbents for predicting CO2 adsorption capacity. RSC Adv 5:103147–103154

Satya Sai P, Krishnaiah K (2005) Development of the pore-size distribution in activated carbon produced from coconut shell char in a fluidized-bed reactor. Ind Eng Chem Res 44:51–60

Shoaib M, Al-Swaidan HM (2015a) Impact of reaction vessel pressure on the synthesis of sliced activated carbon from date palm tree fronds. Hemijska Industrija 69:561–565

Shoaib M, Al-Swaidan HM (2015b) Optimization and characterization of sliced activated carbon prepared from date palm tree fronds by physical activation. Biomass Bioenergy 73:124–134

Smets K, De Jong M, Lupul I, Gryglewicz G, Schreurs S, Carleer R, Yperman J (2016) Rapeseed and raspberry seed cakes as inexpensive raw materials in the production of activated carbon by physical activation: effect of activation conditions on textural and phenol adsorption characteristics. Materials 9:1–19

Song M, Jin B, Xiao R, Yang L, Wu Y, Zhong Z, Huang Y (2013) The comparison of two activation techniques to prepare activated carbon from corn cob. Biomass Bioenergy 48:250–256

Tan IAW, Ahmad AL, Hameed BH (2008) Preparation of activated carbon from coconut husk: optimization study on removal of 2, 4, 6-trichlorophenol using response surface methodology. J Hazard Mater 153:709–717

Tarley CRT, Silveira G, dos Santos WNL, Matos GD, da Silva EGP, Bezerra MA, Miró M, Ferreira SLC (2009) Chemometric tools in electroanalytical chemistry: methods for optimization based on factorial design and response surface methodology. Microchem J 92:58–67

Tay C, Khoshar-Khan M, Md-Desa N, Ab-Ghani Z, Abdul-Talib S (2015) Sustainable optimization of spent mushroom compost activated carbon preparation method using central composite rotatable design response surface methodology. J Eng Sci Technol:40–51

Vivo-Vilches JF, Pérez-Cadenas AF, Maldonado-Hódar FJ, Carrasco-Marín F, Faria RPV, Ribeiro AM, Ferreira AFP, Rodrigues AE (2017) Biogas upgrading by selective adsorption onto CO2 activated carbon from wood pellets. J Environ Chem Eng 5:1386–1393

Wang S, Lu L, Wu D, Lu X, Cao W, Yang T, Zhu Y (2016) Molecular simulation study of the adsorption and diffusion of a mixture of CO2/CH4 in activated carbon: effect of textural properties and surface chemistry. J Chem Eng Data 61:4139–4147

Yang K, Peng J, Xia H, Zhang L, Srinivasakannan C, Guo S (2010) Textural characteristics of activated carbon by single step CO2 activation from coconut shells. J Taiwan Inst Chem Eng 41:367–372

Yusup S, Khan Z, Ahmad MM, Rashidi NA (2014) Optimization of hydrogen production in in-situ catalytic adsorption (ICA) steam gasification based on response surface methodology. Biomass Bioenergy 60:98–107

Acknowledgments

The authors wish to express their greatest appreciation to the YUTP Fundamental Research Grant (grant number 0153AA-E45) and Universiti Teknologi PETRONAS for providing us the financial and technical assistance in completing this research study. The authors would like to extend their appreciation to Kilang Sawit FELCRA Berhad Nasaruddin and Green Global Synergy for providing us raw palm kernel shell as well as char feedstock, and for supporting this research study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Rashidi, N.A., Yusup, S. Production of palm kernel shell-based activated carbon by direct physical activation for carbon dioxide adsorption. Environ Sci Pollut Res 26, 33732–33746 (2019). https://doi.org/10.1007/s11356-018-1903-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-1903-8