Abstract

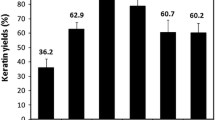

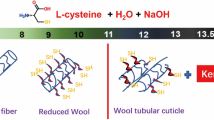

Chicken feather, a potential source of keratin, is often disposed as waste material. Although some methods, i.e., hydrolysis, reduction, and oxidation, have been developed to isolate keratin for composites, it has been limited due to the rising environmental concerns. In this work, a green solvent N-methylmorpholine N-oxide (NMMO) was used to extract keratin from chicken feather waste. Eighty-nine percent of keratin was extracted using 75% NMMO solution. However, the result from size exclusion HPLC showed that most of the keratin degraded into polypeptide with molecular weight of 2189 and only 25.3% regenerated keratin was obtained with molecular weight of 14,485. Analysis of amino acid composition showed a severe damage to the disulfide bonds in keratin during the extraction procedure. Oxidization had an important effect on the reconstitution of the disulfide bonds, which formed a stable three-dimensional net structure in the regenerated keratins. Besides, Raman spectra, NMR, FT-IR, XRD, and TGA were used to characterize the properties of regenerated keratin and raw chicken feather. In the end, a possible mechanism was proposed based on the results.

Similar content being viewed by others

References

Aluigi A, Zoccola M, Vineis C, Tonin C, Ferrero F, Canetti M (2007) Study on the structure and properties of wool keratin regenerated from formic acid. Int J Biol Macromol 41:266–273

Biganska O, Navard P (2008) Morphology of cellulose objects regenerated from cellulose-N-methylmorpholine N-oxide-water solutions. Cellulose 16:179–188

Chen J, Kylie V, Wang X, Nolene B (2014) What happens during natural protein fibre dissolution in ionic liquids. Materials 7:6158–6168

Deb-Choudhury S, Plowman JE, Harland DP (2016) Chapter eleven—isolation and analysis of keratins and keratin-associated proteins from hair and wool. Method Enzymol 568:279–301

El-Kheir AA, Popescu C, Mowafi S, Salama M, El-Sayed H (2015) Physico-chemical properties of keratin-polyvinyl alcohol composite. Fiber Polym 16:537–542

Freddi G, Pessina G, Tsukada M (1999) Swelling and dissolution of silk fibroin (Bombyx mori) in N-methyl morpholine N-oxide. Int J Biol Macromol 24:251–263

Idris A, Vijayaraghavan R, Rana UA, Fredericks D, Patti AF, MacFarlane DR (2013) Dissolution of feather keratin in ionic liquids. Green Chem 15:525–534

Idris A, Vijayaraghavan R, Patti AF, MacFarlane DR (2014a) Distillable protic ionic liquids for keratin dissolution and recovery. ACS Sustain Chem Eng 2:1888–1894

Idris A, Vijayaraghavan R, Rana UA, Patti AF, MacFarlane DR (2014b) Dissolution and regeneration of wool keratin in ionic liquids. Green Chem 16:2857–2864

Isarankura Na Ayutthaya S, Tanpichai S, Wootthikanokkhan J (2015) Keratin extracted from chicken feather waste: extraction, preparation, and structural characterization of the keratin and keratin/biopolymer films and electrospuns. J Polym Environ 23:506–516

Ji Y, Chen J, Lv J, Li Z, Xing L, Ding S (2014) Extraction of keratin with ionic liquids from poultry feather. Sep Purif Technol 132:577–583

Jin X, Wang Y, Yuan J, Shen J (2016) Extraction, characterization, and NO release potential of keratin from human hair. Mater Lett 175:188–190

Kuzuhara A (2011) Raman spectroscopic analysis of L-phenylalanine and hydrolyzed eggwhite protein penetration into keratin fibers. J Appl Polym Sci 122:2680–2689

Ma B, Qiao X, Hou X, Yang Y (2016) Pure keratin membrane and fibers from chicken feather. Int J Biol Macromol 89:614–621

Marsano E, Corsini P, Arosio C, Boschi A, Mormino M, Freddi G (2005) Wet spinning of Bombyx mori silk fibroin dissolved in N-methyl morpholine N-oxide and properties of regenerated fibres. Int J Biol Macromol 37:179–188

Miniaci MC, Irace C, Capuozzo A, Piccolo M, Di Pascale A, Russo A, Lippiello P, Lepre F, Russo G, Santamaria R (2016) Cysteine prevents the reduction in keratin synthesis induced by iron deficiency in human keratinocytes. J Cell Biochem 117:402–412

Plowman JE, Clerens S, Lee E, Harland DP, Dyer JM, Deb-Choudhury S (2014) Ionic liquid-assisted extraction of wool keratin proteins as an aid to MS identification. Anal Methods-UK 6:7305–7311

Poole AJ, Church JS (2015) The effects of physical and chemical treatments on Na2S produced feather keratin films. Int J Biol Macromol 73:99–108

Poole A, Lyons R, Church J (2011) Dissolving feather keratin using sodium sulfide for bio-polymer applications. J Polym Environ 19:995–1004

Reddy N, Jiang Q, Jin E, Shi Z, Hou X, Yang Y (2013) Bio-thermoplastics from grafted chicken feathers for potential biomedical applications. Colloid Surface B 110:51–58

Sharma S, Gupta A (2016) Sustainable management of keratin waste biomass: applications and future perspectives. Braz Arch Biol Technol 59:1–14. doi:10.1590/1678-4324-2016150684

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124:4974–4975

Tanase CE, Spiridon I (2014) PLA/chitosan/keratin composites for biomedical applications. Mat Sci Eng C-Mater 40:242–247

Tran CD, Mututuvari TM (2016) Cellulose, chitosan and keratin composite materials: facile and recyclable synthesis, conformation and properties. ACS Sustain Chem Eng 4:1850–1861

Ullah A, Wu J (2013) Feather fiber-based thermoplastics: effects of different plasticizers on material properties. Macromol Mater Eng 298:153–162

Wang YX, Cao XJ (2012) Extracting keratin from chicken feathers by using a hydrophobic ionic liquid. Process Biochem 47:896–899

Wang B, Yang W, McKittrick J, Meyers MA (2016a) Keratin: structure, mechanical properties, occurrence in biological organisms, and efforts at bioinspiration. Prog Mater Sci 76:229–318

Wang J, Hao S, Luo T, Yang Q, Wang B (2016b) Development of feather keratin nanoparticles and investigation of their hemostatic efficacy. Mat Sci Eng C-Mater 68:768–773

Wang K, Li R, Ma JH, Jian YK, Che JN (2016c) Extracting keratin from wool by using L-cysteine. Green Chem 18:476–481

Wang L, Nie Y, Zhang X, Zeng S, Zhang S, Zheng S (2016d) Synergistic effects of cosolvents on the dissolution of wool keratin using ionic liquids. Chem Eng Technol 39:979–986

Xie H, Li S, Zhang S (2005) Ionic liquids as novel solvents for the dissolution and blending of wool keratin fibers. Green Chem 7:606–608

Xu H, Yang Y (2014) Controlled de-cross-linking and disentanglement of feather keratin for fiber preparation via a novel process. ACS Sustain Chem Eng 2:1404–1410

Xu Y, Zhang Y, Shao H, Hu X (2005) Solubility and rheological behavior of silk fibroin (Bombyx mori) in N-methyl morpholine N-oxide. Int J Biol Macromol 35:155–161

Yen KC, Chen CY, Huang JY, Kuo WT, Lin FH (2016) Fabrication of keratin/fibroin membranes by electrospinning for vascular tissue engineering. J Mater Chem B 4:237–244

Yin XC, Li FY, He YF, Wang Y, Wang RM (2013) Study on effective extraction of chicken feather keratins and their films for controlling drug release. Biomater Sci-UK 1:528–536

Yuan J, Geng J, Xing Z, Shim KJ, Han I, Kim JC, Kang IK, Shen J (2015) Novel wound dressing based on nanofibrous PHBV-keratin mats. J Tissue Eng Regen M 9:1027–1035

Zakrzewska ME, Bogel-Łukasik E, Bogel-Łukasik R (2010) Solubility of carbohydrates in ionic liquids. Energ Fuel 24:737–745

Zhang Y, Zhao W, Yang R (2015) Steam flash explosion assisted dissolution of keratin from feathers. ACS Sustain Chem Eng 3:2036–2042

Zhao W, Yang R, Zhang Y, Wu L (2012) Sustainable and practical utilization of feather keratin by an innovative physicochemical pretreatment: high density steam flash-explosion. Green Chem 14:3352–3360

Zheng S, Nie Y, Zhang S, Zhang X, Wang L (2015) Highly efficient dissolution of wool keratin by dimethylphosphate ionic liquids. ACS Sustain Chem Eng 3:2925–2932

Acknowledgments

The authors greatly acknowledge the financial support from the Enterprise University Research Prospective Program, Jiangsu Province (No. BY2016022-08) and the Fundamental Research Funds for the Central Universities (Nos. JUSRP51723B and JUSRP11502). Yang also appreciates USDA (National Agriculture and Food Initiative, Hatch Act, Multistate Research Project S-1054 (NEB37-037)) and Agricultural Research Division at the University of Nebraska-Lincoln for their support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 284 kb).

Rights and permissions

About this article

Cite this article

Ma, B., Sun, Q., Yang, J. et al. Degradation and regeneration of feather keratin in NMMO solution. Environ Sci Pollut Res 24, 17711–17718 (2017). https://doi.org/10.1007/s11356-017-9410-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9410-x