Abstract

Background

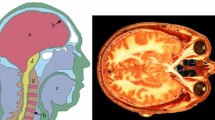

Helmet systems most commonly experience oblique blunt impacts which cause simultaneous linear and rotational accelerations. The ability to attenuate both linear and rotational accelerations by absorbing the normal shock while accommodating large shear deformations with energy dissipation is critical to developing superior helmet liners that prevent traumatic brain injury (TBI).

Objective

To investigate the quasistatic compression-shear response of vertically aligned carbon nanotube (VACNT) foams—which are known for their exceptional specific energy absorption in compression—and explore their potential of accommodating large shear strains at lower shear stress levels, under large compression-shear loadings.

Methodology

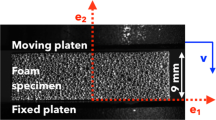

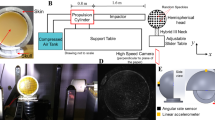

We investigate the quasistatic compression shear response of freestanding vertically aligned carbon nanotube foams subjected to varied initial precompressions. We use in situ high speed microscopy to visualize the microscale deformations during shear.

Results

Vertically aligned carbon nanotube foams exhibit a nonlinear hysteric shear stress–strain response that varies as a function of initial normal precompression. At a given precompression, initial linear response at very low shear strains leads to a behavior showing increasing compliance leading to a plateau like regime at moderate shear strains and then transitions into a stiffening behavior at high shear strains. The shear stress–strain response softens with the increase in initial precompression demonstrating the vertically aligned carbon nanotube foam’s potential to accommodate large shear strains more effectively at severe compression-shear loads unlike other solids that typically jam. In situ high-speed microscopy reveals the unraveling of carbon nanotubes that collectively buckled during precompression, allowing them to accommodate large shear strains at low shear stress levels.

Conclusion

We demonstrate the ability of vertically aligned carbon nanotube to accommodate large shear strains at lower shear stress levels under large compression-shear loadings. We propose a model to predict the compression-shear response at different precompressive strains and use this model to develop a deformation modality diagram that categorizes the dominant deformation mechanisms at different loads along different loading angles.

Similar content being viewed by others

Data Availability

The data supporting the findings of this study are presented in the article.

References

Jorgensen JK, Thoreson AR, Stuart MB, Loyd A, Smith AM, Twardowski C, Gaz DV, Hollman JH, Krause DA, Nan An K et al (2017) Interpreting oblique impact data from an accelerometer-instrumented ice hockey helmet. Proc Inst Mech Eng Pt P J Sports Eng Tech 231(4):307–316. https://doi.org/10.1177/1754337117700549

Barlow GJ, Page C, Drane P, Stapleton SE, Fasel B, Inalpolat M (2021) Combat helmet liner design for blunt impact absorption using multi-output gaussian process surrogates. Proc Inst Mech Eng C J Mech Eng Sci 235(16):2934–2951. https://doi.org/10.1177/0954406220960764

Nasim M, Hasan MJ, Galvanetto U (2022) Impact behavior of energy absorbing helmet liners with pa12 lattice structures: A computational study. Int J Mech Sci 233:107673. https://doi.org/10.1016/j.ijmecsci.2022.107673

Pellman EJ, Viano DC, Tucker AM, Casson IR (2003) Concussion in professional football: Location and direction of helmet impacts-part 2. Neurosurgery 53(6):1328–1341. https://doi.org/10.1227/01.neu.0000093499.20604.21

Baker CE, Martin P, Wilson MH, Ghajari M, Sharp DJ (2022) The relationship between road traffic collision dynamics and traumatic brain injury pathology. Brain Commun 4(2):033. https://doi.org/10.1093/braincomms/fcac033

Khosroshahi SF, Olsson R, Wysocki M, Zaccariotto M, Galvanetto U (2018) Response of a helmet liner under biaxial loading. Polym Testing 72:110–114. https://doi.org/10.1016/j.polymertesting.2018.10.012

Ebrahimi I, Golnaraghi F, Wang GG (2015) Factors influencing the oblique impact test of motorcycle helmets. Traffic Inj Prev 16(4):404–408. https://doi.org/10.1080/15389588.2014.937804

Fernandes F, De Sousa RA (2013) Motorcycle helmets-a state of the art review. Accid Anal Prev 56:1–21. https://doi.org/10.1016/j.aap.2013.03.011

Bliven E, Rouhier A, Tsai S, Willinger R, Bourdet N, Deck C, Madey SM, Bottlang M (2019) Evaluation of a novel bicycle helmet concept in oblique impact testing. Accid Anal Prev 124:58–65. https://doi.org/10.1016/j.aap.2018.12.017

Yu X, Logan I, de Pedro Sarasola I, Dasaratha A, Ghajari M (2022) The protective performance of modern motorcycle helmets under oblique impacts. Ann Biomed Eng 1–15. https://doi.org/10.1007/s10439-022-02963-8

Mosleh Y, Cajka M, Depreitere B, Vander Sloten J, Ivens J (2018) Designing safer composite helmets to reduce rotational accelerations during oblique impacts. Proc Inst Mech Eng [H] 232(5):479–491. https://doi.org/10.1177/0954411918762622

Kleiven S (2013) Why most traumatic brain injuries are not caused by linear acceleration but skull fractures are. Front Bioeng Biotechnol 1:15. https://doi.org/10.3389/fbioe.2013.00015

Carlsen RW, Fawzi AL, Wan Y, Kesari H, Franck C (2021) A quantitative relationship between rotational head kinematics and brain tissue strain from a 2-d parametric finite element analysis. Brain Multiphysics 2:100024. https://doi.org/10.1016/j.brain.2021.100024

Landauer AK, Li X, Franck C, Henann DL (2019) Experimental characterization and hyperelastic constitutive modeling of open-cell elastomeric foams. J Mech Phys Solids 133:103701. https://doi.org/10.1016/j.jmps.2019.103701

Li X, Tao J, Landauer AK, Franck C, Henann DL (2022) Large-deformation constitutive modeling of viscoelastic foams: Application to a closed-cell foam material. J Mech Phys Solids 161:104807. https://doi.org/10.1016/j.jmps.2022.104807

Leng B, Ruan D, Tse KM (2022) Recent bicycle helmet designs and directions for future research: A comprehensive review from material and structural mechanics aspects. Int J Impact Eng 168:104317. https://doi.org/10.1016/j.ijimpeng.2022.104317

Cao A, Dickrell PL, Sawyer WG, Ghasemi-Nejhad MN, Ajayan PM (2005) Super-compressible foamlike carbon nanotube films. Science 310(5752):1307–1310. https://doi.org/10.1126/science.1118957

Chawla K, Gupta A, Bhardwaj AS, Thevamaran R (2022) Superior mechanical properties by exploiting size-effects and multiscale interactions in hierarchically architected foams. Extreme Mech Lett 57:101899. https://doi.org/10.1016/j.eml.2022.101899

Thevamaran R, Meshot ER, Daraio C (2015) Shock formation and rate effects in impacted carbon nanotube foams. Carbon 84:390–398. https://doi.org/10.1016/j.carbon.2014.12.006

Gupta A, Griesbach C, Cai J, Weigand S, Meshot ER, Thevamaran R (2022) Origins of mechanical preconditioning in hierarchical nanofibrous materials. Extreme Mech Lett 50:101576. https://doi.org/10.1016/j.eml.2021.101576

Suhr J, Victor P, Ci L, Sreekala S, Zhang X, Nalamasu O, Ajayan P (2007) Fatigue resistance of aligned carbon nanotube arrays under cyclic compression. Nat Nanotechnol 2(7):417–421. https://doi.org/10.1038/nnano.2007.186

Raney JR, Fraternali F, Daraio C (2013) Rate-independent dissipation and loading direction effects in compressed carbon nanotube arrays. Nanotechnology 24(25):255707. https://doi.org/10.1088/0957-4484/24/25/255707

Lattanzi L, Thevamaran R, De Nardo L, Daraio C (2015) Dynamic behavior of vertically aligned carbon nanotube foams with patterned microstructure. Adv Eng Mater 17(10):1470–1479. https://doi.org/10.1002/adem.201400571

Xu M, Futaba DN, Yamada T, Yumura M, Hata K (2010) Carbon nanotubes with temperature-invariant viscoelasticity from-196 to 1000 c. Science 330(6009):1364–1368. https://doi.org/10.1126/science.1194865

Yang X, He P, Gao H (2011) Modeling frequency-and temperature-invariant dissipative behaviors of randomly entangled carbon nanotube networks under cyclic loading. Nano Res 4(12):1191–1198. https://doi.org/10.1007/s12274-011-0169-y

Fan Y-Y, Kaufmann A, Mukasyan A, Varma A (2006) Single- and multi-wall carbon nanotubes produced using the floating catalyst method: Synthesis, purification and hydrogen up-take. Carbon 44(11):2160–2170. https://doi.org/10.1016/j.carbon.2006.03.009

José-Yacamán M, Miki-Yoshida M, Rendon L, Santiesteban J (1993) Catalytic growth of carbon microtubules with fullerene structure. Appl Phys Lett 62(6):657–659. https://doi.org/10.1063/1.109315

Hata K, Futaba DN, Mizuno K, Namai T, Yumura M, Iijima S (2004) Water-assisted highly efficient synthesis of impurity-free single-walled carbon nanotubes. Science 306(5700):1362–1364. https://doi.org/10.1126/science.1104962

Maschmann MR (2015) Integrated simulation of active carbon nanotube forest growth and mechanical compression. Carbon 86:26–37. https://doi.org/10.1016/j.carbon.2015.01.013

Bedewy M, Meshot ER, Guo H, Verploegen EA, Lu W, Hart AJ (2009) Collective mechanism for the evolution and self-termination of vertically aligned carbon nanotube growth. J Phys Chem C 113(48):20576–20582. https://doi.org/10.1021/jp904152v

Acknowledgements

We acknowledge the financial support from the U.S. Office of Naval Research under PANTHER award number N000142112044 and N000142112916 through Dr. Timothy Bentley. We also acknowledge the useful conversations with Prof. Christian Franck and Dr. Jialiang Tao on designing the compression-shear experimental apparatus and the nature of TBI.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

K. Chawla and R. Thevamaran are members of SEM.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maheswaran, B., Chawla, K. & Thevamaran, R. Mitigating Oblique Impacts by Unraveling of Buckled Carbon Nanotubes in Helmet Liners. Exp Mech 64, 197–209 (2024). https://doi.org/10.1007/s11340-023-01013-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-01013-1