Abstract

Background

The current literature reporting the TPMS lattice structure compression lacks the general perspective to study the effect of material, geometry, and strain rate on their compression performance.

Objective

Hence, this study focused upon investigating their performance under uniaxial compression for different materials, geometries, and strain rates to build a general perspective.

Method

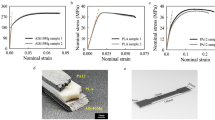

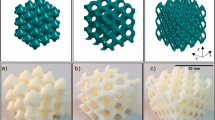

Triply periodic minimal surface (TPMS) lattice structures are designed and manufactured using fused deposition modeling (FDM) with two different thermoplastic fibers – poly(LacticAcid) and Acrylo-Butadiene-Styrene. The manufactured TPMS lattice structures are compressed at different strain rates and the results have been compared to analyze the effect of material, design, and strain rate variation on their compression performance.

Results

It is observed that the PLA lattice structures have higher mechanical strength but lower compressibility than their ABS counterparts. Among the different TPMS architectures, the Schwarz D had the highest strength and displayed a bulk solid type of compression pattern, independent of the material. The other two designs - Gyroid and Schwarz P had strengths of about 50% and 30% of the Schwarz D lattice structures and showed a layered periodic deformation pattern.

Conclusion

The Gyroid lattice structures show an average behavior of both Schwarz lattices. Increasing strain rate also had a significant but design dependent impact on the mechanical properties. The lattice structures showed a non-linear patterned variation in mechanical properties against increasing strain rate. The strain energy absorbed per unit solid fraction is also compared to give more in-depth information regarding the role of design and geometry.

Similar content being viewed by others

References

Brakke K. http://facstaff.susqu.edu/brakke/evolver/examples/periodic/periodic.html

Kelly CN, Kahra C, Maier HJ, Gall K (2021) Processing, structure, and properties of additively manufactured titanium scaffolds with gyroid-sheet architecture. Additive Manuf 41:101916

Zhang L, Feih S, Daynes S, Chang S, Wang MY, Wei J, Lu WF (2018) Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading. Additive Manuf 23:505–515

Zhu H, Li M, Huang X, Qi D, Nogueira LP, Yuan X, Liu W, Lei Z, Jiang J, Dai H, Xiao J (2021) 3D printed tricalcium phosphate-bioglass scaffold with gyroid structure enhance bone ingrowth in challenging bone defect treatment. Appl Mater Today 25:101166

Osgouei MA, Li Y, Vahid A, Ataee A, Wen C (2020) High strength porous PLA gyroid scaffolds manufactured via fused deposition modelling for tissue engineering applications. Smart Mater Med 2:15–25

Germain L, Fuentes CA, van Vuure AW, Rieux desA, Dupont-Gillain C (2018) 3D-printed biodegradable gyroid scaffolds for tissue engineering applications. Mater Des 151:113–122

Zabidi AZ, Li S, Felfel RM, Thomas KG, Grant DM, McNally D, Scothford C (2019) Computational mechanical characterization of geometrically transformed Schwarz P lattice tissue scaffolds fabricated via two photon polymerization (2PP). Additive Manuf 25:399–411

Vijayavenkataraman S, Kuan LV, Lu WF (2020) 3D printed ceramic triply periodic minimal surface structured for design of functionally graded bone implants. Mater Des 191:108602

Ma S, Tang Q, Han X, Feng Q, Song J, Setchi R, Liu Y, Liu Y, Goulas A, Engstrom DS, Tse YY, Zhen N (2020) Manufacturability, mechanical properties, Mass-Transport Properties and Biocompatibility of Triply Periodic Minimal Surface (TPMS) porous scaffolds fabricated by selective laser melting. Mater Des 195:109034

Maskery I, Ashcroft IA (2020) The deformation and elastic anisotropy of a new gyroid-based honeycomb made by laser sintering. Additive Manuf 36:101548

Luo JW, Chen L, Min T, Shan F, Kang Q, Tao WQ (2020) Macroscopic transport properties of gyroid structures based on pore-scale studies: permeability, diffusivity and thermal conductivity. Int J Heat Mass Transf 146:118837

Thomas N, Sreedhar N, Al-Ketan O, Rowshan R, Abu Al-Rub RK, Arafat H (2018) 3D printed triply periodic minimal surfaces as spacers for enhanced heat and mass transfer in membrane distillation. Desalination 443:256–271

Keshavarzan M, Kadkhodaei M, badrossamay M, Ravari MRK (2020) Investigation on the failure mechanism of triply periodic minimal surface cellular structures fabricated by vat photopolymerization additive manufacturing under compressive loadings. Mech Mater 140:103150

Jia H, Lei H, Wang H, Wang P, Meng J, Li C, Zhou H, Zhang X, Fang D (2020) An experimental and numerical investigation of compressive response of designed Schwarz primitive triply periodic minimal surface with non-uniform shell thickness. Extreme Mech Lett 37:100671

Peng C, Tran P (2020) Bioinspired functionally graded gyroid sandwich panel subjected to impulsive loadings. Compos part B: Eng 188:107773

Abueidda DW, Al-Rub BM, Abu RK, Bergstrom JS, Sobh NA, Jasiuk I (2017) Mechancial properties of 3D printed polymeric cellular materials with triply periodic minimal surface architectures. Mater Des 122:255–267

Yu S, Sun J, Bai J (2019) Investigation of functionally graded TPMS structures fabricated by additive manufacturing. Mater Des 182:108021

Gunther F, Wagner M, Pilz S, Gebert A, Zimmermann M (2022) Design procedure for triply periodic minimal surface based biomimetic scaffolds. Jounral of the Mechanical Behavior of Biomedical Materials 126:104871

Montazerian H, Mohamed MGA, Montazeri MM, Kheiri S, Milani AS, Kim K, Hoorfar M (2019) Permeability and mechanical properties of gradient porous PDMS scaffolds fabricated by 3D-printed sacrificial templates designed with minimal surfaces. Acta Biomater 96:149–160

Restrepo S, Ocampo S, Ramirez JA, Paucar C, Garcia C (2017) Mechancial properties of ceramic structures based on Triply Periodic Minimal Surface (TPMS) processed by 3D printing. IOP Conf Ser J Phys Conf Ser 935:012036

Bobbert FSL, Lietaert K, Eftekhari AA, Pouran B, Ahmadi SM, Weinans H, Zadpoor AA (2017) Additively manufactured metallic porou biomeaterials based on minimal surfaces: a unique combination of topological, mechanical, and mass transport properties. Acta Biomater 53:572–584

Chavan H, Mishra AK, Kumar A (2020) Open-source designing for additive manufacturing of metallic triply periodic minimal surfaces. In: Advances in Lightweight Materials and Structures, Springer

Upadhyay RK, Mishra AK, Kumar A (2020) Mechanical degradation of 3D printed PLA in simulated marine environment. Surf Interface 21:100778

Harshitha V, Rao SS (2019) Design and analysis of ISO standard bolt and nut in FDM 3D printer using PLA and ABS materials. Materials today: Proc 19–2:583–588

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm no conflict of interest with any party regarding the work presented in this study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mishra, A.K., Kumar, A. Compression Behavior of Triply Periodic Minimal Surface Polymer Lattice Structures. Exp Mech 63, 609–620 (2023). https://doi.org/10.1007/s11340-023-00940-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00940-3