Abstract

Background

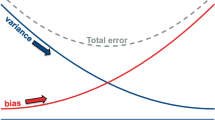

Incremental hole-drilling (IHD) and X-ray diffraction (XRD) are two of the most commonly used methods to measure through-thickness residual stress variation. IHD readily provides interior stress data, but the technique is prone to large uncertainty near the surface when steep stress gradients exist. XRD provides excellent near-surface data but insufficient penetration to readily define the stress distribution below the surface. To exploit the best features of each of these complementary residual stress measurement techniques, a means of combining measurements from XRD and IHD was recently demonstrated through the imposition of constraints on a series expansion solution. The regularized integral method is, however, the industry standard. A need therefore exists for a similar approach using the latter method.

Objective

Develop and demonstrate an approach to constrain the solution of the regularized integral method using data from complementary measurement techniques.

Methods

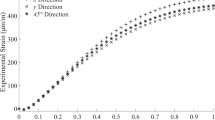

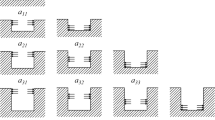

Constraints are enforced using the Lagrange multiplier method. The resulting equations are of closed form and make use of readily available information. The method is demonstrated on an aluminium alloy 7075 specimen of 10 mm thickness subjected to laser shock peening.

Results

Residual stress distributions obtained using the constrained and standard regularized integral methods compare well throughout the hole depth. The effect of incorporating XRD data into the constrained solution is localized to the near-surface region where the uncertainty is reduced.

Conclusions

Incorporation of XRD data into IHD results is readily achieved and allows the advantages of both techniques to be utilised while minimizing their shortcomings.

Similar content being viewed by others

References

Ding K, Ye L (2006) Laser shock peening performance and process simulation. Woodhead Publishing in Materials, Taylor & Francis. ISBN 9780849334443

Hammond D, Meguid S (1990) Crack propagation in the presence of shot-peening residual stresses. Eng Fract Mech 37(2):373–387. ISSN 0013-7944. https://doi.org/10.1016/0013-7944(90)90048-L

Luo K, Wang C, Li Y, Luo M, Huang S, Hua X, Lu J (2014) Effects of laser shock peening and groove spacing on the wear behavior of non-smooth surface fabricated by laser surface texturing. Appl Surf Sci 313:600–606. ISSN 0169-4332. https://doi.org/10.1016/j.apsusc.2014.06.029

Yilbas B, Gondal M, Arif A, Shuja S (2004) Laser shock processing of Ti-6Al-4V alloy. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 218(5):473–482. https://doi.org/10.1177/095440540421800501

Liu Q, Ding K, Ye L, Rey C, Barter S, Sharp P, Clark G (2004) Spallation-like phenomenon induced by laser shock peening surface treatment on 7050 aluminum alloy. In: Proceedings of Structural Integrity and Fracture International Conference (SIF’04), Brisbane, Australia, 26-29 September 2004, The University of Queensland: Brisbane, Australia. pp 235–240

Kandil F, Lord D, Fry A (2001) NPL report MATC(A)04: a review of residual stress measurement methods - A guide to technique selection. Tech. rep, National Physical Laboratory Materials Centre, Teddington, UK

Schajer G, Yang L (1994) Residual-stress measurement in orthotropic materials using the hole-drilling method. Exp Mech 34(4):324–333. ISSN 00144851. https://doi.org/10.1007/BF02325147

ASTM E837-20 (2020) Standard test method for determining residual stresses by the hole-drilling strain-gage method. ASTM International, West Conshohocken, PA. www.astm.org

Schajer G (1988) Measurement of non-uniform residual stresses using the hole-drilling method. Part II. Practical application of the integral method. Journal of Engineering Materials and Technology, Transactions of the ASME 110(4):344–349. ISSN 00944289. https://doi.org/10.1115/1.3226059

Schajer G, Whitehead P (2013) Hole drilling and ring coring. In: Schajer G (ed) Practical Residual Stress Measurement Methods, John Wiley & Sons, Ltd, chap 2. pp 29–64. ISBN 9781118402832. https://doi.org/10.1002/9781118402832.ch2

Prime M, Hill M (2006) Uncertainty, model error, and order selection for series-expanded, residual-stress inverse solutions. J Eng Mater Technol 128(2):175. ISSN 00944289. https://doi.org/10.1115/1.2172278

Oettel R (2000) The determination of uncertainties in residual stress measurement (using the hole drilling technique). Code of Practice 15, Issue 1, EU Project No. SMT4-CT97-2165 (1):18. ISSN 00392103. https://doi.org/10.1007/bf02327502

Schajer G, Altus E (1996) Stress calculation error analysis for incremental hole-drilling residual stress measurements. Journal of Engineering Materials and Technology-Transactions of the ASME 118(1):120–126. ISSN 00944289. https://doi.org/10.1115/1.2805924

Tikhonov A, Goncharsky A, Stepanov V, Yagola A (1995) Numerical methods for the solution of Ill-posed problems. Kluwer, Dordrecht

Petan L, Ocañ J, Grum J (2016) Effects of laser shock peening on the surface integrity of 18% Ni maraging steel. Strojniski Vestnik/J Mech Eng Sci. ISSN 00392480. https://doi.org/10.5545/sv-jme.2015.3305

Nobre J, Polese C, van Staden S (2020) Incremental hole drilling residual stress measurement in thin aluminum alloy plates subjected to laser shock peening. Exp Mech 60(1):553–564. https://doi.org/10.1007/s11340-020-00586-5

Blödorn R, Bonomo L, Viotti M, Schroeter R, Albertazzi A (2017) Calibratixugh Fem simulations for the hole-drilling method considering the real hole geometry. Exp Tech. ISSN 17471567. https://doi.org/10.1007/s40799-016-0152-3

Cullity B, Stock S (2001) Elements of X-ray Diffraction, Third Edition. Prentice-Hall

Valentini E, Beghini M, Bertini L, Santus C, Benedetti M (2011) Procedure to perform a validated incremental hole drilling measurement: application to shot peening residual stresses. Strain 47(s1):e605–e618. https://doi.org/10.1111/j.1475-1305.2009.00664.x

Withers P, Bhadeshia H (2001) Residual stress. Part 1 - Measurement techniques. Mater Sci Technol 17(4):355–365. https://doi.org/10.1179/026708301101509980

Fitzpatrick M, Fry A, Holdway P, Kandil F, J S, Suominen L (2005) Measurement good practice guide no. 52: Determination of Residual Stresses by X-ray Diffraction - Issue 2. Tech. rep., National Physical Laboratory, Teddington, UK

François M, Convert F, Branchu S (2000) French round-robin test of X-ray stress determination on a shot-peened steel. Exp Mech 40(4):361–368. ISSN 1741-2765. https://doi.org/10.1007/BF02326481

HS (Society of Automotive Engineers) HS (2003) Residual stress measurement by X-ray diffraction: HS-784. SAE International. ISBN 9780768010695

Glaser D, Newby M, Polese C, Berthe L, Venter A, Marais D, Nobre J, Styger G, Paddea S, van Staden S (2018) Evaluation of residual stresses introduced by laser shock peening in steel using different measurement techniques. In: Materials Research Proceedings, Materials Research Forum LLC., Millersville PA, USA, vol 4. pp 45–50. https://doi.org/10.21741/9781945291678-7

Tang Z, Dong X, Geng Y, Wang K, Duan W, Gao M, Mei X (2022) The effect of warm laser shock peening on the thermal stability of compressive residual stress and the hot corrosion resistance of Ni-based single-crystal superalloy. Opt Laser Technol 146:107556. ISSN 0030-3992. https://doi.org/10.1016/j.optlastec.2021.107556

Smit T, Reid R (2021) A method to combine residual stress measurements from XRD and IHD using series expansion. Exp Mech 61(6):1029–1043. https://doi.org/10.1007/s11340-021-00719-4

Schajer G (1981) Application of finite element calculations to residual stress measurements. J Eng Mater Technol 103(2):157. ISSN 00944289. https://doi.org/10.1115/1.3224988

Smit T, Reid R (2020) Use of power series expansion for residual stress determination by the incremental hole-drilling technique. Exp Mech 60(9):1301–1314. ISSN 17412765. https://doi.org/10.1007/s11340-020-00642-0

Schajer G, Prime M (2006) Use of inverse solutions for residual stress measurements. J Eng Mater Technol 128(3):375. ISSN 00944289. https://doi.org/10.1115/1.2204952

Bertsekas D (1982) Constrained optimization and lagrange multiplier methods. Academic Press. ISBN 978-0-12-093480-5. https://doi.org/10.1016/C2013-0-10366-2

Nocedal J, Wright S (2006) Numerical optimization. Springer, New York, NY. ISBN 978-0-387-40065-5. https://doi.org/10.1007/978-0-387-40065-5

Karush W (1939) Minima of functions of several variables with inequalities as side constraints. M Sc Dissertation Dept of Mathematics, Univ of Chicago

Kuhn H, Tucker A (1951) Nonlinear programming. In: Proceedings of the Second Berkeley Symposium on Mathematical Statistics and Probability, Berkeley: University of California Press

Handbook A (1990) Volume 2: properties and selection: nonferrous alloys and special-purpose materials. ASM International. ISBN 978-0-87170-378-1

Macherauch E, Müller P (1961) Das sin2y-verfahren der röntgenographischen spannungsmessung. Zeitschrift für Angewandte Physik 13:305–312

Noyan I, Cohen J (1987) Residual stress: measurement by diffraction and interpretation. Springer-Verlag, New York. ISBN 978-1-4613-9570-6. https://doi.org/10.1007/978-1-4613-9570-6

Schajer G (2020) Compact calibration data for hole-drilling residual stress measurements in finite-thickness specimens. Exp Mech 60(5):665–678. ISSN 1741-2765. https://doi.org/10.1007/s11340-020-00587-4

Smit T, Reid R (2018) Residual stress measurement in composite laminates using incremental hole-drilling with power series. Exp Mech 58(8):1221–1235. ISSN 17412765. https://doi.org/10.1007/s11340-018-0403-6

Parlevliet P, Bersee H, Beukers A (2007) Residual stresses in thermoplastic composites – a study of the literature. Part III: Effects of thermal residual stresses. Compos A Appl Sci Manuf 38(6):1581–1596. ISSN 1359835X. https://doi.org/10.1016/j.compositesa.2006.12.005

Schajer G (2010) Hole-drilling residual stress measurements at 75: origins, advances. Opportunities. Experimental Mechanics 50(2):245–253. ISSN 1741-2765. https://doi.org/10.1007/s11340-009-9285-y

Smit T, Reid R (2020) Tikhonov regularization with incremental hole-drilling and the integral method in cross-ply composite laminates. Exp Mech 60(8):1135–1148. ISSN 17412765. https://doi.org/10.1007/s11340-020-00629-x

BIPM, IEC, IFCC, ILAC, IUPAC, IUPAP, ISO, OIML (2008) Evaluation of measurement data - Supplement 1 to the “Guide to the expression of uncertainty in measurement” - Propagation of distributions using a Monte Carlo method. JCGM 101: 2008

Peral D, de Vicente J, Porro J, Ocaña J (2017) Uncertainty analysis for non-uniform residual stresses determined by the hole drilling strain gauge method. Measurement: Journal of the International Measurement Confederation 97:51–63. ISSN 02632241. https://doi.org/10.1016/j.measurement.2016.11.010

Nobre J, Kornmeier M, Dias A, Scholtes B (2000) Use of the hole-drilling method for measuring residual stresses in highly stressed shot-peened surfaces. Exp Mech 40:289–297. https://doi.org/10.1007/BF02327502

Acknowledgements

The authors wish to thank Dr Daniel Glaser of the National Laser Centre (NLC) at the Council for Scientific and Industrial Research (CSIR), Pretoria, South Africa, for conducting the XRD measurements used in this work. The authors wish to thank the Rental Pool Programme from the National Laser Centre (NLC) at the Council for Scientific and Industrial Research (CSIR), Pretoria, South Africa.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Research Involving Human and Animal Participants

Not applicable.

Informed Consent

Not applicable.

Conflicts of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Smit, T., Reid, R. Imposition of Constraints on the Regularized Integral Method of Incremental Hole-Drilling. Exp Mech 62, 1257–1266 (2022). https://doi.org/10.1007/s11340-022-00851-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00851-9