Abstract

Background

Understanding how materials respond to rapid changes in temperature (thermal shock) is important to the development of materials and components for service in the challenging conditions found in aerospace and energy applications, among others. State of the art approaches to evaluating thermal shock are limited by the uncertainty involved with the characterization of the experimental thermal boundary conditions, typically convective and with phase change, which makes it difficult to develop and validate computational models of materials undergoing thermal shock.

Objective

The objective of this work is to support the development of computational models of thermal shock by demonstrating a method of experimentally characterizing materials undergoing rapid heating that enables accurate and repeatable measurement of thermal boundary conditions, and the dynamic thermal response of the test article.

Methods

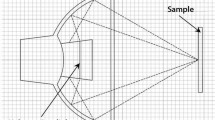

We have developed an experimental system in which test articles are heated radiatively on one surface by focused light having a peak intensity between 30 W/cm2 – 60 W/cm2, and insulated on all other surfaces. The dynamic thermal response of the heated surface is measured using infrared thermography with full-field temperature maps acquired every 143 ms.

Results

The radiative boundary conditions were measured with an uncertainty of ± 3% at 95% confidence across the entire heated surface, and varied locally by 2.6%-3.2% between repeated tests at the same conditions. Comparisons of dynamic thermal response and results from a linear-elastic finite element simulation showed good agreement between peak and average surface temperature, spatial temperature distribution across the heated surface, and time-to-fracture.

Conclusions

The results demonstrate that the experimental technique presented yields thermal shock data of sufficient fidelity to be used in the development and validation of computational thermal shock models.

Similar content being viewed by others

Abbreviations

- OPT:

-

Optical camera

- IR:

-

IR camera

- TC:

-

Thermocouple

- RTD:

-

Resistance temperature detector

- A:

-

Surface area [m2]

- h:

-

Convection heat transfer coefficient [Wm−2 K−1]

- k:

-

Thermal conductivity [Wm−1 K−1]

- T:

-

Temperature [°C or K]

- L:

-

Length [m]

- Ra:

-

Rayleigh number [-]

- g:

-

Acceleration of gravity [9.81 ms−2]

- cp :

-

Specific heat [J(kgK)−1

- ε:

-

Thermal emissivity [-]

- µ:

-

Viscosity [kg(ms)−1]

- β:

-

Coefficient of volume expansion [K−1]

- α:

-

Absorptivity [-]

- ρ:

-

Density [kgm−3]

- σ:

-

Stress [Pa]

- rad:

-

Radiative

- s:

-

Surface

- L:

-

Averaged over the length dimension

- ∞:

-

Atmospheric properties

- a:

-

Allowable stress

- flex:

-

Flexural

- mp:

-

Maximum principal stress

- mar:

-

Stress margin

References

Niihara K, Singh JP, Hasselman D (1982) Observations on the Characteristics of a Fluidized Bed for the Thermal Shock Testing of Brittle Ceramics. J Mater Sci 17(9):2553–2559

Ribeiro GC, Resende WS, Rodrigues JA (2016) Thermal Shock Resistance of a Refractory Castable Containing Andalusite Aggregate. Ceram Int 42(16):19167–19171

Absi J, Glandus JC (2004) Improved Method for Severe Thermal Shocks Testing of Ceramics by Water Quenching. J Eur Ceram Soc 24(9):2835–2838

Alan A (1968) "Thermal Shock Apparatus," Thermal Shock Apparatus (US3365930A)

Kerezsi BB, Kotousov AG, Price J (2000) Experimental Apparatus for Thermal Shock Fatigue Investigations. Int J Press Vessels Pip 77(7):425–434

Lu TJ, Fleck NA (1998) The Thermal Shock Resistance of Solids. Acta Mater 46(13):4755–4768

Andreev K, Luchini B, Rodrigues MJ (2020) Role of Fatigue in Damage Development of Refractories Under Thermal Shock Loads of Different Intensity. Ceram Int 46(13):20707–20716

Andreev K, Tadaion V, Zhu Q (2019) Thermal and Mechanical Cyclic Tests and Fracture Mechanics Parameters as Indicators of Thermal Shock Resistance – Case Study on Silica Refractories. J Eur Ceram Soc 39(4):1650–1659

Bolcavage A, Feuerstein A, Foster J (2004) Thermal Shock Testing of Thermal Barrier Coating/Bondcoat Systems. J Mater Eng Perform 13(4):389–397

He R, Qu Z, Liang D (2017) Rapid Heating Thermal Shock Study of Ultra High Temperature Ceramics using an in Situ Testing Method. J Adv Ceramics 6(4):279–287

Cavalieri AL (2000) Evaluation of the Heat Transfer Coefficient in Thermal Shock of Alumina Disks. Mater Sci Eng, A 276(1–2):76–82

Cavalieri AL (2001) Numerical Simulation of the Thermal Shock of Alumina Disks with Different Surface Finish. J Eur Ceram Soc 21(9):1205–1212

Hamidouche M, Bouaouadja N, Olagnon C (2003) Thermal Shock Behaviour of Mullite Ceramic. Ceram Int 29(6):599–609

Mignard F, Olagnon C, Fantozzi G (1996) Thermal Shock Behaviour of a Coarse Grain Porous Alumina. J Mater Sci 31(8):2131–2138

Liu Y, He Y, Yuan Z (2014) Numerical and Experimental Study on Thermal Shock Damage of CVD ZnS Infrared Window Material. J Alloy Compd 589:101–108

Ogura T, Kanamori I, Murano K (1984) "Thermal Shock Chamber," Thermal Shock Chamber (US4575257A) 1–6

Panda PK, Kannan TS, Dubois J (2002) Thermal Shock and Thermal Fatigue Study of Ceramic Materials on a Newly Developed Ascending Thermal Shock Test Equipment. Sci Technol Adv Mater 3(4):327

Wei GC, Walsh J (1989) Hot-Gas-Jet Method and Apparatus for Thermal-Shock Testing. J Am Ceram Soc 72(7):1286–1289

Takahashi H, Ishikawa T, Okugawa D (1993) "Thermal Shock and Thermal Fatigue Behavior of Advanced Ceramics."Springer 543–554

Jian CY, Hashida T, Takahashi H (1995) Thermal Shock and Fatigue Resistance Evaluation of Functionally Graded Coating for Gas Turbine Blades by Laser Heating Method. Compos Eng 5(7):879–889

Gilbert A, Kokini K, Sankarasubramanian S (2008) Thermal Fracture of Zirconia–mullite Composite Thermal Barrier Coatings Under Thermal Shock: An Experimental Study. Surf Coat Technol 202(10):2152–2161

Benz R, Naoumidis A, Nickel H (1987) Thermal Shock Testing of Ceramics with Pulsed Laser Irradiation. J Nucl Mater 150(2):128–139

Awaji H, Honda S, Nishikawa T (1997) Thermal Shock Parameters of Ceramics Evaluated by Infrared Radiation Heating. JSME Intern J Series A Solid Mech Mater Eng 40(4):414–422

Honda S, Ogihara Y, Kishi T (2009) Estimation of Thermal Shock Resistance of Fine Porous Alumina by Infrared Radiation Heating Method. J Ceram Soc Jpn 117(1371):1208–1215

Schneider GA, Petzow G (1991) Thermal Shock Testing of Ceramics—a New Testing Method. J Am Ceram Soc 74(1):98–102

Vedula VR, Green DJ, Hellmann JR (1998) Test Methodology for the Thermal Shock Characterization of Ceramics. J Mater Sci 33(22):5427–5432

Debuyser M, Sjöström J, Lange D (2017) Behaviour of Monolithic and Laminated Glass Exposed to Radiant Heating. Constr Build Mater 130:212–229

Mizutani Y, Nishikawa T, Fukui T (1995) Thermal Shock Fracture of Ceramic Disk Under Rapid Heating. J Ceram Soc Jpn 103(1197):525–528

Merklinger V, Christ M (2019) A New Thermal Shock Application-Related Testing Method for Ceramic Components. Interceram-International Ceramic Review 68(1):22–25

Boubault A, Yellowhair J, Ho CK (2017) Design and Characterization of a 7.2 kW Solar Simulator. J SolEnergy Eng 139(3):031012–031018

Gill R, Bush E, Haueter, P (2015) "Characterization of a 6 kW High-Flux Solar Simulator with an Array of Xenon Arc Lamps Capable of Concentrations of nearly 5000 Suns." The Rev Sci Instruments 86(12):125107

Levêque Gaël, Roman Bader, Wojciech Lipiński (2016) Experimental and Numerical Characterization of a New 45 kWel Multisource High-Flux Solar Simulator. Opt Express 24(22):A1360–A1373

Siegel NP, Roba JP (2018) "Design, Modeling, and Characterization of a 10 kWe Metal Halide High Flux Solar Simulator." J Solar Energy Eng 140(4):045001

Roba JP, Siegel NP (2017) The Design of Metal Halide-Based High Flux Solar Simulators: Optical Model Development and Empirical Validation. Sol Energy 157:818–826

Petrasch J, Coray P, Meier A (2007) A Novel 50 kW 11,000 Suns High-Flux Solar Simulator Based on an Array of Xenon Arc Lamps. J SolEnergy Eng 129(4):405

Notz PK, Subia SR, Hopkins MM (2007) "Aria 1.5: User Manual," Sandia National Laboratories, SAND2007–2734, Albuquerque

MitchellŁ JA, Gullerud AS, Scherzinger WM (2001) "Adagio: non-linear quasi-static structural response using the sierra framework," Sandia National Laboratories, SAND2001–1634A, Albuquerque

Auerkari P (1996) "Mechanical and physical properties of engineering alumina ceramics." Technic Res Centre Finland Espoo

Hottel HC (1954) "Radiant heat transmission." WH McAdams

DEH K, Agrawal S, Pratap A (2000) "A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II," International conference on parallel problem solving from nature & Anonymous Springer, Berlin. 849–858

CoorsTek (2021) "AD-998 EBM Chemistry Data Sheet." (4/16/)

Acknowledgements

This work was funded by a grant from Ball Aerospace and Technologies Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Sean Babiniec is an employee of Ball Aerospace Technologies, the sponsor of this work. Nathan Siegel and Tim Chilemba declare that they have no conflict of interest related to this work or its dissemination.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Siegel, N.P., Chilemba, T.H. & Babiniec, S.M. Thermal Shock Testing of Ceramics Using Non-Uniform Radiant Heating. Exp Mech 62, 493–504 (2022). https://doi.org/10.1007/s11340-021-00797-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00797-4