Abstract

Background

Because of considerable experimental difficulties for measuring the viscoelastic Poisson´s ratio of polymers and the scarcity of reported data of this property for most of polymers, in particular, elastomers, new measurement methods and procedures need to be developed.

Objective

The aim of this article is to provide a simple, suitable and reliable procedure to allow the determination of the viscoelastic Poisson’s ratio of elastomers from simple creep strain measurements based on digital image correlation.

Methods

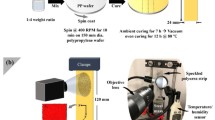

To illustrate the proposed procedure, a silicone rubber was tested and analyzed. It consisted of performing creep tests at different stresses and temperatures for 10 min (short-term creep tests) measuring simultaneous axial and transverse strains with a DIC equipment. Creep strain functions in axial and transverse direction were obtained employing a creep model. Then, the strain functions were used to calculate the viscoelastic Poisson´s ratio through a transformation method and to obtain their long-term curves.

Results

The results obtained demonstrated significant stress and temperature dependency of the viscoelastic Poisson´s ratio for the silicone rubber. It was observed that the viscoelastic Poisson’s ratio increases with temperature but tends to a certain value, and tends to 0.5 for higher temperatures. Overall, the proposed procedure exhibited notable ease and accuracy for the assessment of viscoelastic Poisson´s ratio of elastomers.

Conclusions

Finally, the methodology followed in this work can be a potential alternative tool for the characterization of viscoelastic Poisson´s ratio of elastomers, which is currently scarce in literature.

Similar content being viewed by others

References

Spathis G, Kontou E (2012) Creep failure time prediction of polymers and polymer composites. Compos Sci Technol 72(9):959964. https://doi.org/10.1016/j.compscitech.2012.03.018

Brostow W (2009) Reliability and prediction of long-term performance of polymer-based materials. Pure Appl Chem 81(3):417–432. https://doi.org/10.1351/PAC-CON-08-08-03

Luo R (2016) Creep simulation and experiment for rubber springs. Proc Inst Mech Eng Pt L J Mater Des Appl 230(2):681–688. https://doi.org/10.1177/1464420715576558

Luo R (2019) Creep prediction with temperature effect and experimental verification of rubber suspension components used in rail vehicles. Proc Inst Mech Eng Pt C J Mechan 233(11):3950–3963. https://doi.org/10.1177/0954406218809143

Sahu R, Patra K, Szpunar J (2015) Experimental study and numerical modelling of creep and stress relaxation of dielectric elastomers. Strain 51:43–54. https://doi.org/10.1111/str.12117

Vennemann N (2012) Characterization of thermoplastic elastomers by means of temperature scanning stress relaxation measurements. In: Zaki El-Sonbati Thermoplastic Elastomers, Adel, INTECH, pp 347–370. https://doi.org/10.5772/35976

Kenneth TG, Celina M, Bernstein R (2003) Validation of improved methods for predicting long-term elastomeric seal lifetimes from compression stress–relaxation and oxygen consumption techniques. Polym Degrad Stabil 82(1):25–35. https://doi.org/10.1016/S0141-3910(03)00159-9

Farfán-Cabrera LI, Pascual-Francisco JB, Barragan-Perez O, Gallardo-Hernandez EA, Susarrey-Huerta O (2017) Determination of creep compliance, recovery and Poisson’s ratio of elastomers by means of digital image correlation (DIC). Polym Test 59:245–252. https://doi.org/10.1016/j.polymertesting.2017.02.010

Tweedie CA, Van Vliet KJ (2006) Contact creep compliance of viscoelastic materials via nanoindentation. J Mater Res 21(6):1576–1589. https://doi.org/10.1557/jmr.2006.0197

Oyen ML (2005) Spherical indentation creep following ramp loading. J Mater Res 20(8):2094–2100. https://doi.org/10.1557/JMR.2005.0259

Rubin A, Favier D, Danieau P, Giraudel M, Chambard JP, Gauthier C (2016) Direct observation of contact on non transparent viscoelastic polymers surfaces: a new way to study creep and recovery. Prog Org Coatings 99:134–139. https://doi.org/10.1016/j.porgcoat.2016.05.014

Findley WN, Lai JS, Onaran K (1989) Creep and relaxation of nonlinear viscoelastic materials. Dover publications, New York

Pandini S, Pegoretti A (2008) Time, temperature, and strain effects on viscoelastic Poisson’s ratio of epoxy resins. Polym Eng Sci 48:1434–1441. https://doi.org/10.1002/pen.21060

Ernst LJ, Zhang GQ, Jansen KMB, Bressers HJL (2003) Time and Temperature-Dependent Thermo-Mechanical Modeling of a Packaging Molding Compound and its Effect on Packaging Process Stresses. ASME J Electron Packag 125(4):539–548. https://doi.org/10.1115/1.1604156

Yao JQ, Parry TV, Unsworth A, Cunningham JL (1994) Contact Mechanics of Soft Layer Artificial Hip Joints. Proc Inst Mech Eng Pt H J Eng Med 208(4):206–215. https://doi.org/10.1243/PIME_PROC_1994_208_290_02

Święszkowski W, Ku DN, Bersee HEN, Kurzydlowski KJ (2006) An elastic material for cartilage replacement in an arthritic shoulder joint. Biomaterials 27(8):1534–1541. https://doi.org/10.1016/j.biomaterials.2005.08.032

Bergström JS, Rimnac CM, Kurtz SM (2003) Prediction of multiaxial mechanical behavior for conventional and highly crosslinked UHMWPE using a hybrid constitutive model. Biomaterials 24(8):1365–1380. https://doi.org/10.1016/S0142-9612(02)00514-8

Al-Hiddabi SA, Pervez T, Qamar SZ, Al-Jahwari FK, Marketz F, Al-Houqani S, van de Velden M (2015) Analytical model of elastomer seal performance in oil wells. Appl Math Model 39(10–11):2836–2848. https://doi.org/10.1016/j.apm.2014.10.028

van der Varst PGTh, Kortsmit WG (1992) Notes on the lateral contraction of linear isotropic visco-elastic materials. Arch Appl Mech 62:338–346. https://doi.org/10.1007/BF00788641

Tschoegl NW, Knauss WG, Emri I (2002) Poisson’s Ratio in Linear Viscoelasticity – A Critical Review. Mech Time-Depend Mat 6:3–51. https://doi.org/10.1023/A:1014411503170

Ashrafi H, Shariyat M (2010) A mathematical approach for describing the time-dependent Poisson's ratio of viscoelastic ligaments mechanical characteristics of biological tissues. 17th ICBME 1–5. https://doi.org/10.1109/ICBME.2010.5705018

O’Brien DJ, Sottos NR, White SR (2007) Cure-dependent Viscoelastic Poisson’s Ratio of Epoxy. Exp Mech 47:237–249. https://doi.org/10.1007/s11340-006-9013-9

Tscharnuter D, Jerabek M, Major Z (2011) Time-dependent poisson’s ratio of polypropylene compounds for various strain histories. Mech Time-Depend Mater 15:15–28. https://doi.org/10.1007/s11043-010-9121-x

Lu H, Zhang X, Knauss WG (1997) Uniaxial, Shear, and Poisson Relaxation and Their Conversion to Bulk Relaxation: Studies on Poly(Methy1 Methacrylate). Polymer Eng Sci 37(6):1053–1064. https://doi.org/10.1002/pen.11750

Pandini S, Pegoretti A (2011) Time and temperature effects on Poisson’s ratio of poly(butylene terephthalate). Exp Polym Let 5(8):685–697. https://doi.org/10.3144/expresspolymlett.2011.67

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):062001. https://doi.org/10.1088/0957-0233/20/6/062001

Pascual-Francisco JB, Barragán-Pérez O, Susarrey-Huerta O, Michtchenko A, Martínez-García A, Farfán-Cabrera LI (2017) The effectiveness of shearography and digital image correlation for the study of creep in elastomers. Mater Res Express 4(11):115301. https://doi.org/10.1088/2053-1591/aa94ee

Pritchard RH, Lava P, Debruyne D, Terentjev EM (2013) Precise determination of the Poisson ratio in soft materials with 2D digital image correlation. Soft Matter 9:6037–6045. https://doi.org/10.1039/C3SM50901J

Li J, Dan X, Xu W, Wang Y, Yang G, Yang L (2017) 3D digital image correlation using single color camera pseudo-stereo system. Opt Laser Technol 95:1–7. https://doi.org/10.1016/j.optlastec.2017.03.030

Pascual-Francisco JB, Farfan-Cabrera LI, Susarrey-Huerta O (2020) Characterization of tension set behavior of a silicone rubber at different loads and temperatures via digital image correlation. Polym Test 81:106226. https://doi.org/10.1016/j.polymertesting.2019.106226

Frankovsky P, Virgala I, Hudak P, Kotska J (2013) The use the of digital image correlation in a strain analysis. Int J Appl Mech Eng 18(4):1283–1292. https://doi.org/10.2478/ijame-2013-0079

Choi D, Thorpe JL, Hanna RB (1991) Image analysis to measure strain in wood and paper. Wood Sci Technol 25(4):251–262. https://doi.org/10.1007/BF00225465

Pan B, Xie H, Guo Z, Hua T (2009) Full-field strain measurement using a two-dimensional Savitzky-Golay digital differentiator in digital image correlation. Opt Eng 46:033601. https://doi.org/10.1117/1.2714926

Ernst LJ, Zhang GQ, Jansen KMB, Bressers HJL (2003) Time- and Temperature-Dependent Thermo-Mechanical Modeling of a Packaging Molding Compound and its Effect on Packaging Process Stresses. ASME J Electron Packag 125(4):539–548. https://doi.org/10.1115/1.1604156

Flitney RK (2014) Seals and Sealing Handbook, 6th ed. Butterworth-Heinemann. https://doi.org/10.1016/C2012-0-03302-9

Kuptsov AH, Zhizhin GN (1998) Handbook of Fourier Transform Raman and Infrared Spectra of Polymers, 1st edn. Elsevier Science, Amsterdam

Molnár L, Huba A (2001) Measurement of dynamic properties of silicone rubbers. Period Polytech Mech Eng 45(1): 87–94. https://pp.bme.hu/me/article/view/1411

Drozdov AD, Dorfmann A (2002) The effect of temperature on the viscoelastic response of rubbery polymers at finite strains. Acta Mech 154:189–214. https://doi.org/10.1007/BF01170707

Jazouli S, Luo W, Brémand F (2006) Nonlinear creep behavior of viscoelastic polycarbonate. J Mater Sci 41:531–536. https://doi.org/10.1007/s10853-005-2276-1

Grassia L, Amore AD, Simon SL (2010) On the Viscoelastic Poisson’s Ratio in Amorphous Polymers. J Rheol 54:1009–1022. https://doi.org/10.1122/1.3473811

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farfan-Cabrera, L.I., Pascual-Francisco, J.B. An Experimental Methodological Approach for Obtaining Viscoelastic Poisson’s Ratio of Elastomers from Creep Strain DIC-Based Measurements. Exp Mech 62, 287–297 (2022). https://doi.org/10.1007/s11340-021-00792-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00792-9