Abstract

Background

Deformation properties of porous metallic fibre networks are strongly dependent on their architecture, mainly fibre orientation, besides being a function of constituent fibre material and its geometrical parameters. Hence, it is important to comprehend and evaluate the effect of individual fibre orientation and fibre-segment aspect ratio on the mechanical properties of porous metallic fibre networks.

Objective

To investigate the effect of fibre orientation on its deformation characteristics and to analytically explain the observed mechanical behaviour.

Methods

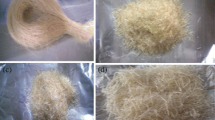

Present work captures the deformation of inclined copper fibres (in the range of 0° to 45°), mounted on a novel paper-tab framework, under tensile loading. A 1D analytical model has also been developed to elucidate the inclined fibre deformation and yield characteristics.

Results

An increase in fibre inclination angle (from 0° to 45°), exhibits a decreased yield force. The model validates the experiments, and for elastic region establishes that the axial, shear forces and bending moment increase with fibre inclination angle, where the increase in axial force is predominant. The model further establishes the effect of fibre-segment aspect ratio on the yield force of fibre networks and determines that increase in diameter of the fibres has the same effect as decrease in segment length with regards to these forces.

Conclusions

The study establishes the effect of fibre inclination angle on the deformation behaviour of porous metallic fibre network materials and can potentially be used to optimise their architecture for targeted applications.

Similar content being viewed by others

References

Gibson LJ, Ashby MF (1997) Cellular Solids - Structure and Properties. Cambridge University Press, Cambridge UK

Nakajima H (2007) Fabrication, properties and application of porous metals with directional pores. Prog Mater Sci 52:1091–1173. https://doi.org/10.1016/j.pmatsci.2006.09.001

Davies GJ, Zhen S (1983) Metallic foams: their production, properties and applications. J Mater Sci 18:1899–1911. https://doi.org/10.1007/BF00554981

Liu P, He G, Wu LH (2008) Fabrication of sintered steel wire mesh and its compressive properties. Mater Sci Eng, A 489:21–28. https://doi.org/10.1016/j.msea.2007.11.060

Markaki AE, Gergely V, Cockburn A, Clyne TW (2003) Production of a highly porous material by liquid phase sintering of short ferritic stainless steel fibres and a preliminary study of its mechanical behaviour. Compos Sci Technol 63:2345–2351. https://doi.org/10.1016/S0266-3538(03)00267-7

Zhao TF, Jin MZ, Chen CQ (2013) A phenomenological elastoplastic model for porous metal fiber sintered sheets. Mater Sci Eng, A 582:188–193. https://doi.org/10.1016/j.msea.2013.06.042

Jayanty S, Crowe J, Berhan L (2011) Auxetic fibre networks and their composites. Physica Status Solidi (B) Basic Research 248:73–81. https://doi.org/10.1002/pssb.201083973

Rodney D, Gadot B, Martinez OR et al (2016) Reversible dilatancy in entangled single-wire materials. Nat Mater 15:72–77. https://doi.org/10.1038/nmat4429

Neelakantan S, Tan JC, Markaki AE (2015) Out-of-plane auxeticity in sintered fibre network mats. Scripta Mater 106:30–33. https://doi.org/10.1016/j.scriptamat.2015.04.028

Picu RC (2011) Mechanics of random fiber networks - A review. Soft Matter 7:6768–6785. https://doi.org/10.1039/c1sm05022b

Ashby MF (2006) The properties of foams and lattices. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 364:15–30. https://doi.org/10.1098/rsta.2005.1678

Zhou W, Tang Y, Liu B et al (2012) Compressive properties of porous metal fiber sintered sheet produced by solid-state sintering process. Mater Des 35:414–418. https://doi.org/10.1016/j.matdes.2011.09.026

Xi Z, Zhu J, Tang H et al (2010) Progress of application researches of porous fiber metals. Materials 4:816–824. https://doi.org/10.3390/ma4040816

Zou C, Zhang E, Li M, Zeng S (2008) Preparation, microstructure and mechanical properties of porous titanium sintered by Ti fibres. J Mater Sci - Mater Med 19:401–405. https://doi.org/10.1007/s10856-006-0103-0

Clyne TW, Markaki AE, Tan JC (2005) Mechanical and magnetic properties of metal fibre networks, with and without a polymeric matrix. Compos Sci Technol 65:2492–2499. https://doi.org/10.1016/j.compscitech.2005.05.037

Ducheyne P, Aernoudt E, Meester P (1978) The mechanical behaviour of porous austenitic stainless steel fibre structures. J Mater Sci 13:2650–2658. https://doi.org/10.1007/BF02402752

Neelakantan S, Bosbach W, Woodhouse J, Markaki AE (2014) Characterization and deformation response of orthotropic fibre networks with auxetic out-of-plane behaviour. Acta Mater 66:326–339. https://doi.org/10.1016/j.actamat.2013.11.020

Markaki AE, Clyne TW (2003) Mechanics of thin ultra-light stainless steel sandwich sheet material Part II. Resistance to delamination Acta Materialia 51:1351–1357. https://doi.org/10.1016/S1359-6454(02)00529-3

Tan Q, Liu P, Du C et al (2009) Mechanical behaviors of quasi-ordered entangled aluminum alloy wire material. Mater Sci Eng, A 527:38–44. https://doi.org/10.1016/j.msea.2009.07.022

Wu SL, Liu XM, Chu PK et al (2008) Phase transformation behavior of porous NiTi alloys fabricated by capsule-free hot isostatic pressing. J Alloy Compd 449:139–143. https://doi.org/10.1016/j.jallcom.2006.01.144

Liu P, He G, Wu L (2009) Structure deformation and failure of sintered steel wire mesh under torsion loading. Mater Des 30:2264–2268. https://doi.org/10.1016/j.matdes.2008.09.007

Liu P, He G, Wu LH (2009) Impact behavior of entangled steel wire material. Mater Charact 60:900–906. https://doi.org/10.1016/j.matchar.2009.03.001

Zhou W, Tang Y, Pan M et al (2009) Experimental investigation on uniaxial tensile properties of high-porosity metal fiber sintered sheet. Mater Sci Eng, A 525:133–137. https://doi.org/10.1016/j.msea.2009.06.025

Li C, Zhou Z (2021) Charpy impact behavior of a novel stainless steel powder wire mesh composite porous plate. Materials 14:1–13. https://doi.org/10.3390/ma14112924

Zok FW, Levi CG (2001) Mechanical properties of porous-matrix ceramic composites. Adv Eng Mater 3:15–23. https://doi.org/10.1002/1527-2648(200101)3:1/2%3c15::aid-adem15%3e3.3.co;2-1

Gómez-Gómez A, Moyano JJ, Osendi MI et al (2021) The effect of rod orientation on the strength of highly porous filament printed 3D SiC ceramic architectures. Bol Soc Esp Ceram Vidrio 60:119–127. https://doi.org/10.1016/j.bsecv.2020.01.013

ASTM C 1557, 2003 Standard Test Method for Tensile Strength and Young’s Modulus of Fibers Astm 1–10 https://doi.org/10.1520/C1557-14.2

Shames IH, Pitarresi JM (2009) Introduction to Solid Mechanics. PHI Learning Private Limited, New Delhi

Vega G, Haddi A, Imad A (2009) Investigation of process parameters effect on the copper-wire drawing. Mater Des 30:3308–3312. https://doi.org/10.1016/j.matdes.2008.12.006

Huang IT, Hung FY, Lui TS et al (2011) A study on the tensile fracture mechanism of 15 μm copper wire after EFO process. Microelectron Reliab 51:25–29. https://doi.org/10.1016/j.microrel.2010.04.007

Bartos PJM, Duris M (1998) Inclined tensile strength of steel fibres in a cement based composite. Composites, 25 25:89–101. https://doi.org/10.1016/0010-4361(94)90110-4

Dieter GE (2011) Mechanical metallurgy., Third. McGraw Hill Education (India) Private Limited, New Delhi

Cuadrado A, Yánez A, Martel O et al (2017) Influence of load orientation and of types of loads on the mechanical properties of porous Ti6Al4V biomaterials. Mater Des 135:309–318. https://doi.org/10.1016/j.matdes.2017.09.045

Acknowledgements

This work is part of the Early Career Research (ECR) grant award (Ref. no.: ECR/2016/001953) funded by Science and Engineering Research Board (SERB) of Department of Science and Technology (DST), India. One of the authors acknowledge the support. The authors acknowledge the technical support provided by Department of Applied Mechanics and the Department of Materials Science and Engineering, IIT Delhi. The authors also acknowledge Dr. Jayant Jain of IIT Delhi for providing the copper fibre material.

Funding

This work is part of the Early Career Research (ECR) grant award (Ref. no.: ECR/2016/001953) funded by Science and Engineering Research Board (SERB) of Department of Science and Technology (DST), India.

Author information

Authors and Affiliations

Contributions

Aravi Muzaffar: Investigation, Methodology, Data Curation, Formal analysis, Writing – Original Draft; Sushma Santapuri: Methodology, Validation, Data Curation, Visualization, Writing – Review & Editing; Rajesh Prasad: Supervision, Visualization, Writing – Review & Editing; Suresh Neelakantan: Conceptualization, Supervision, Project administration, Resources, Writing – Review & Editing, Funding acquisition.

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muzaffar, A., Santapuri, S., Prasad, R. et al. An Experimental and Analytical Investigation on the Deformation of Inclined Metallic Fibres for Optimized Design of Fibrous Porous Materials. Exp Mech 62, 427–439 (2022). https://doi.org/10.1007/s11340-021-00780-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00780-z