Abstract

Background

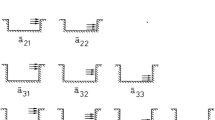

There is a large geometrical variation among the commercially available strain gauge rosettes used for hole-drilling residual stress measurements. Detailed calibration data are readily available only for the rosette types described in ASTM Standard Test Procedure E837-20. This makes it difficult for the ordinary practitioner to use other rosette types for hole-drilling residual stress measurements.

Objective

The aim here is to develop a numerical adjustment scheme that can accommodate variations in strain gauge length and width, and enable the publicly available calibration data provided in E837-20 to be used with general rosette types.

Results

The proposed numerical adjustment scheme gives calibration results typically within ~ 2% of the values found from a custom computation based on the fine details of the strain gauge geometry. This effect may cause ~ 3% variations in the computed residual stresses.

Conclusions

The computed calibration data are suitable for practical hole-drilling measurements. The differences in the calibration data from the custom results are small compared with the range of the stress measurement errors typically encountered in practical hole-drilling.

Similar content being viewed by others

References

Schajer GS, Whitehead PS (2018) Hole-Drilling Method for Measuring Residual Stress. Morgan & Claypool, Williston, VT, USA

Grant PV, Lord JD, Whitehead PS (2002) The Measurement of Residual Stresses by the Incremental Hole Drilling Technique. Measurement Good Practice Guide No.53, National Physical Laboratory, Teddington, UK

Vishay Measurements Group, Inc. (1993) Measurement of Residual Stresses by the Hole-Drilling Strain-Gage Method. Tech Note TN-503–6. Vishay Measurements Group, Inc., Raleigh, NC. 16pp

Soete W, Vancrombrugge R (1950) An Industrial Method for the Determination of Residual Stresses. Proceedings SESA 8(1):17–28

Boiten RG, ten Cate W (1952) A Routine Method for the Measurement of Residual Stresses in Plates. Appl Sci Res A3(5):317–343

Kelsey RA (1956) Measuring Non-Uniform Residual Stresses by the Hole Drilling Method. Proceedings SESA 14(1):181–194

Rendler NJ, Vigness I (1966) Hole-drilling Strain-gage Method of Measuring Residual Stresses. Exp Mech 6(12):577–586

ASTM (2020) Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. Standard Test Method E837–20. American Society for Testing and Materials, West Conshohocken, PA

Schajer GS (1993) Use of Displacement Data to Calculate Strain Gauge Response in Non-Uniform Strain Fields. Strain 29(1):9–13

Bush AJ, Kromer FJ (1973) Simplification of the Hole-Drilling Method of Residual Stress Measurement. ISA Trans 12(3):249–259

Muskhelishvili NI (19S3) Some Basic Problems in the Mathematical Theory of Elasticity. Noordhoff, Groningen, Holland, pp. 202–204

Schajer GS (1981) Application of Finite Element Calculations to Residual Stress Measurements. J Eng Mater Technol 103(2):157–163

Perry CC (1982) The Elusive Goal or Accurate Strain Gage Measurements at Stress Concentrations. Epsilonics 2(2):10–11

Schajer GS (1988) Measurement of non-uniform residual stresses using the hole-drilling method. Part I. J Eng Mater Technol 110(4):338–343

Schajer GS (2020) Compact Calibration Data for Hole-Drilling Residual Stress Measurements in Finite-Thickness Specimens. Exp Mech 60(5):665–678

HBM GmbH (2019) Strain Gauges First Choice for Strain Measurement. https://www.hbm.com/en/2073/strain-gauge-pdf-catalog/. pp.75–78. Accessed 8 Jun 2021

Kyowa Electronic Instruments Co., Ltd (2021) KFGS for Boring Method. https://www.kyowa-ei.com/eng/product/category/strain_gages/kfgs_senkou/index.html. Accessed 8 Jun 2021

Acknowledgements

This work was financially supported through a grant from the Natural Sciences and Engineering Research Council of Canada (NSERC). Dr. Juuso Heikkinen kindly reviewed the manuscript and made many helpful suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that he has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Schajer, G.S. Universal Calibration Constants for Strain Gauge Hole-Drilling Residual Stress Measurements. Exp Mech 62, 351–358 (2022). https://doi.org/10.1007/s11340-021-00771-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00771-0