Abstract

The multireflection grazing incidence X-ray diffraction method (MGIXD) was used to analyze the surface residual stresses in 7050 Al alloy samples. This technique can provide a non-destructive stress profile in function of sample depth, avoiding the relaxation effects intrinsic to destructive methods. The state of residual stress in aeronautical aluminium samples was modulated by milling and shot peening processes. After structural characterization, the residual stress states of the samples were analyzed by multireflection and conventional stress measurement methods. The milled samples presented tensile surface residual stress relaxation attributed to thermal effects and the shot peened samples showed strong compressive stress at sub-surface, which intensity was reduced near the surface. The residual stress profiles of the Al samples were obtained by MGIXD method that evidenced properties commonly undetected in conventional residual stress studies.

Similar content being viewed by others

References

Prime MB (2018) The two-way relationship between residual stress and fatigue/fracture. In: Carroll J, Xia S, Beese A, Berke R, Pataky G (eds) Fracture, Fatigue, Failure and Damage Evolution, Conference proceedings of the Society for Experimental Mechanics Series, vol 7. Springer, Cham, pp 19–23

Carvalho ALM, Voorwald HJC (2007) Influence of shot peening and hard chromium electroplating on the fatigue strength of 7050-T7451 aluminum alloy. Int J Fatigue 29:1282–1291

Withers PJ (2007) Residual stress and its role in failure. Rep Prog Phys 70:2211–2264

Zhuang WZ, Halford GR (2001) Investigation of residual stress relaxation under cyclic load. Int J Fatigue 23:31–37

Krishna LR et al (2018) Influence of prior shot peening variables on the fatigue life of micro arc oxidation coated 6061-T6 Al alloy. Int J Fatigue 106:165–174

Noyan IC, Cohen JB (1999). Residual stress measurement by diffraction and interpretation. Springer series on materials research and engineering. Springer-Verlag, Heidelberg chs. 5 and 6

Bonner N, Wimpory R, Webster G, Fry A, Kandil F (2002) Measurement of residual stress through a shot peened surface subjected to successive material removal. Mater Sci Forum 404:653–658

Alkaisee R, Peng RL (2014) Influence of layer removal methods in residual stress profiling of a shot peened steel using X-ray diffraction. Adv Mater Res 996:175–180

Dolle H (1979) The influence of multiaxial stress states, stress gradients and elastic anisotropy on the evaluation of (residual) stresses by X-rays. J Appl Crystallogr 12:489–501

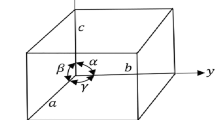

Skrzypek SJ, Baczmański A, Ratuszek W, Kusior E (2001) New approach to stress analysis based on grazing-incidence X-ray diffraction. J Appl Crystallogr 34:427–435

Prevey PS (1986) X-Ray diffraction residual stress techiniques. Metals Handbook 10:380–392

Baczmanski A, Braham C, Seiler W, Shiraki N (2004) Multi-reflection method and grazing incidence geometry used for stress measurement by X-ray diffraction. Surf Coat Technol 182:43–54

Watkins TR, Cavin OB, Bai J, Chediak JA (2003) Residual stress determinations using parallel beam optics. Adv X-ray Anal 46:119–129

Genzel C (1994) Formalism for the evaluation of strongly non-linear surface stress fields by X-ray diffraction performed in the scattering vector mode. Physica status solidi (a) 146, 629–637

Marciszko M et al (2017) Stress measurements by multi-reflection grazing-incidence X-ray diffraction method (MGIXD) using different radiation wavelengths and different incident angles. Acta Mater 123:157–166

Toby BH, Von Dreele RB (2013) GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J Appl Crystallogr 46:544–549

Tang ZT (2008) Study on residual stresses in milling Aluminium alloy 7050-T7451, in: advanced design and manufacture to gain a competitive edge: new manufacturing techniques and their role in improving enterprise performance, springer

Luan W, Jiang C, Ji V (2009) Thermal relaxation of residual stresses in shot peened surface layer on Ti2Al composite at elevated temperatures. Mater Trans 50:1499–1501

Benedetti M, Fontanari V, Scardi P, Ricardo CLA, Bandini M (2009) Reverse bending fatigue of shot peened 7075-T651 aluminium alloy: the role of residual stress relaxation. Int J Fatigue 31:1225–1236

Acknowledgements

Support from CNPq (National Council for Scientific and Technological Development) is thankfully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Righetti, V.A.N., Campos, T.M.B., Robatto, L.B. et al. Non-destructive Surface Residual Stress Profiling by Multireflection Grazing Incidence X-Ray Diffraction: a 7050 Al Alloy Study. Exp Mech 60, 475–480 (2020). https://doi.org/10.1007/s11340-019-00578-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00578-0