Abstract

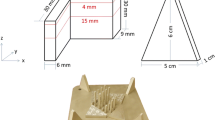

Metal components fabricated through additive manufacturing processes generally require post-processing in the form of thermal treatments in order to relieve residual stresses or facilitate development of a desired microstructure. In this work, the thermal strain response of multiple variations of 420 stainless steel made using a laser-powder bed fusion were probed during a low temperature (315 °C) heat treatment. Surface strains in both the build plane and build direction were measured in situ during the thermal cycle using a three-dimensional digital image correlation method. The effect of specimen build parameters on the thermal expansion coefficients and relief of residual strains are presented. Results show that specimens with lower layer build heights produced both slightly higher thermal expansion coefficients and higher degrees of strain relief after the thermal cycle. The addition of niobium and molybdenum content was also found to reduce the coefficient of thermal expansion and lower the strain relief found after the low temperature cycle.

Similar content being viewed by others

References

Schade C, Schaberl J, Lawley A (2007) Stainless Steel AISI Grades for PM Applications. Advances In Powder Metallurgy And Particulate Materials 2:07

Wang K, Chang B, Chen J, Fu H, Lin Y, Lei Y (2017) Effect of molybdenum on the microstructures and properties of stainless steel coatings by laser cladding. Appl Sci 7(10):1065

Angrish A (2014) A Critical Analysis of Additive Manufacturing Technologies for Aerospace Applications. In: Aerospace Conference, IEEE 2014, pp. 1–6

Frazier WE (2014) Metal Additive Manufacturing: A Review. J Mater Eng Perform 23(6):1917–1928

Gao W et al (2015) The status, challenges, and future of additive manufacturing in engineering. Comput Aided Des 69:65–89

Vastola G, Zhang G, Pei Q, Zhang Y-W (2016) Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Additive Manufacturing 12:231–239

Panda BK, Sahoo S (2018) Numerical simulation of residual stress in laser based additive manufacturing process. In: IOP Conference Series: Materials Science and Engineering, vol. 338, no. 1, p. 012030: IOP Publishing

Mukherjee T, Zhang W, DebRoy T (2017) An improved prediction of residual stresses and distortion in additive manufacturing. Comput Mater Sci 126:360–372

Liu W, Ma J, Kong F, Liu S, Kovacevic R (2015) Numerical modeling and experimental verification of residual stress in autogenous laser welding of high-strength steel. Lasers in Manufacturing and Materials Processing 2(1):24–42

Brnic J, Turkalj G, Canadija M, Lanc D, Krscanski S (2011) Martensitic stainless steel AISI 420—mechanical properties, creep and fracture toughness. Mechanics of Time-Dependent Materials 15(4):341–352

A. S. Corporation (2015) 420 stainless steel data sheet. www.aksteel.com

I. Lindquist Steels. Technical Bulletin: AISI 420 stainless steel. www.lindquiststeels.com, vol. TBA42097

Abbasi-Khazaei B, Mollaahmadi A (2017) Rapid Tempering of Martensitic Stainless Steel AISI420: Microstructure, Mechanical and Corrosion Properties. J Mater Eng Perform 26(4):1626–1633

da Silva GF, Tavares SSM, Pardal JM, Silva MR, de Abreu HFG (2011) Influence of heat treatments on toughness and sensitization of a Ti-alloyed supermartensitic stainless steel. J Mater Sci 46(24):7737–7744

Barlow LD, Du Toit M (2011) Effect of Austenitizing Heat Treatment on the Microstructure and Hardness of Martensitic Stainless Steel AISI 420. J Mater Eng Perform 21(7):1327–1336

Groen M, Zijlstra G, San-Martin D, Post J, De Hosson JTM (2018) Product shape change by internal stresses. Mater Des 157:492–500

Zijlstra G, Groen M, Post J, Ocelík V, De Hosson JTM (2016) On the role of the residual stress state in product manufacturing. Mater Des 105:375–380

Do T, Kwon P, Shin CS (2017) Process development toward full-density stainless steel parts with binder jetting printing. Int J Mach Tools Manuf 121:50–60

Ghasri-Khouzani M et al (2017) Experimental measurement of residual stress and distortion in additively manufactured stainless steel components with various dimensions. Mater Sci Eng A 707:689–700

Nelson DV (1982) Effects of residual stress on fatigue crack propagation. In: Residual stress effects in fatigue. ASTM International, West Conshohocken

Prime MB (2018) The Two-Way Relationship Between Residual Stress and Fatigue/Fracture, pp. 19–23

Bing P, Hui-min X, Tao H, Asundi A (2009) Measurement of coefficient of thermal expansion of films using digital image correlation method. Polym Test 28(1):75–83

De Strycker M, Schueremans L, Van Paepegem W, Debruyne D (2010) Measuring the thermal expansion coefficient of tubular steel specimens with digital image correlation techniques. Opt Lasers Eng 48(10):978–986

Berke RB, Sebastian CM, Chona R, Patterson EA, Lambros J (2016) High Temperature Vibratory Response of Hastelloy-X: Stereo-DIC Measurements and Image Decomposition Analysis. Exp Mech 56(2):231–243

Nath SD, Irrinki H, Gupta G, Kearns M, Gulsoy O, Atre S (2019) Microstructure-property relationships of 420 stainless steel fabricated by laser-powder bed fusion. Powder Technol 343:738–746

Davis JR, A. S. M. I. H. Committee (1994) Stainless steels (ASM specialty handbook). ASM International, Materials Park

Acknowledgements

The authors like to thank the Walmart Foundation for funding aspects of this work, and Sandvik Osprey for providing the powders used in this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Momenzadeh, N., Nath, S., Berfield, T. et al. In Situ Measurement of Thermal Strain Development in 420 Stainless Steel Additive Manufactured Metals. Exp Mech 59, 819–827 (2019). https://doi.org/10.1007/s11340-019-00513-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00513-3