Abstract

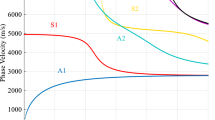

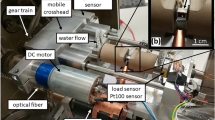

Two strain localization modes: the Piobert-Lüders band propagation and the development of necking, were investigated in uniaxial tensile tests for a low alloyed and low carbon steel. These two macroscopic localization phenomena were simultaneously monitored by speckle interferometry (ESPI) and acoustic emission (AE). The coupling of these two experimental techniques gives complementary information about strain localization features and mechanisms. For Lüders bands, it was found that the acoustic activity heard during the travel of the Piobert-Lüders band varies in closely correlated to the tensile force fluctuations, the relations between strain rate, band velocity, band width and plastic strain were investigated. Although the strain rate in the wake of the wave front is not always zero, the acoustic activity remains concentrated in the wave front itself. For necking, the acoustic activity is found to decrease regularly through the homogeneous plasticity stage and the diffuse necking stage and then increases when the localized necking starts, while ESPI patterns show a gradual strain concentration.

Similar content being viewed by others

References

Hähner P (1994) Theory of solitary plastic waves – part I: Lüders bands in polycrystals. Appl Physics A Solids Surf 58:41–48

Wattrisse B, Chrysochoos A, Muracciole J-M, Némoz-Gaillard M (2001) Kinematic manifestations of localisation phenomena in steels by digital image correlation. Eur J Mech A Solids 20:189–211

Plekhov OA, Naimark OB, Saintier N, Palin-Luc T (2009) Elastic–plastic transition in iron: structural and thermodynamic features. Tech Phys 54(8):1141–1146

Shabadi R, Kumar S, Roven HJ, Dwarakadasa ES (2004) Characterisation of PLC and parameters using laser speckle technique. Mater Sci Eng A 364:140–150

Neuhäuser H, Klose FB, Hagemanna F, Weidenmüller J, Dierke H, Hähner P (2004) On the PLC effect in strain-rate and stress-rate controlled tests–studies by laser scanning extensometry. J Alloys Compd 378:13–18

Klose FB, Hagemann F, Hähner P, Neuhäuser H (2004) Investigation of the Portevin-le Châtelier effect in al-3wt.%mg alloys by strain-rate and stress-rate controlled tensile tests. Mater Sci Eng A 387–389:93

Jiang Z, Zhang Q, Jiang H, Chen Z, Wu X (2005) Spatial characteristics of the Portevin-le Chatelier deformation bands in al-4 at%cu polycrystals. Mater Sci Eng A 403:154–164

Dierke H, Krawehl F, Graff S, Forest S, Săchl J, Neuhäuser H (2007) Portevin–le Chatelier effect in al–mg alloys: influence of obstacles – experiments and modelling. Comput Mater Sci 39:106–112

N. Ranc, D. Wagner (2008) Experimental study by pyrometry of Portevin–Le Châtelier plastic instabilities − Type A to type B transition. Mater Sci Eng A, 474(1–2):188–196

Min J, Hector LG, Carsley JE, Stoughton TB, Carlson BE, Lin J (2015) Spatio-temporal characteristics of plastic instability in AA5182-O during biaxial deformation. Mater Des 83:786–794

Cottrell AH, Bilby BA (1948) Dislocation theory of yielding and strain ageing of iron. Proc Phys Soc 62:49–62

Lomer WM (1952) The yield phenomenon in polycrystalline mild steel. J Mech Phys Solids 1:64–73

Johnston WG, Gilman JJ (1959) Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals. J Appl Phys 30:129–144

Butler JF (1962) Lüders front propagation in low carbon steels. J Mech Phys Solids 10:313–334

Hall EO (1970) Yield point phenomena in metals and alloys. Plenum Press, New York

Zhang J, Jiang Y (2005) Lüders bands propagation of 1045 steel under multiaxial stress state. Int J Plast 21(3):651–670

Coër J, Manach PY, Laurent H, Oliveira MC, Menezes LF (2013) Piobert–Lüders plateau and Portevin–le Chatelier effect in an al–mg alloy in simple shear original research. Mech Res Commun 48:1–7

Sun HB, Yoshida F, Ohmori M, Ma X (2003) Effect of strain rate on Lüders band propagating velocity and Lüders strain for annealed mild steel under uniaxial tension. Mater Lett 57(29):4535–4539

Hutanu R, Clapham L, Rogge RB (2005) Intergranular strain and texture in steel Lüders bands. Acta Mater 53(12):3517–3524

Louche H, Chrysochoos A (2001) Thermal and dissipative effects accompanying Lüders band propagation. Mater Sci Eng A 307(1–2):15–22

Considère A (1885) Mémoire sur l’Emploi du Fer et de l’Acier dans les Constructions. Annales des Ponts et Chaussées 9:574–775

Swift HW (1952) Plastic instability under plane stress. J Mech Phys Solids 1:1–18

Hill R (1952) On discontinuous plastics states, with special reference to localized necking in thin sheets. J Mech Phys Solids 1:19–30

Rudnicki JW, Rice JR (1975) Conditions for the localization of deformation in pressure-sensitive dilatant materials. J Mech Phys Solids 23:371–394

Chien WY, Pan J, Tang SC (2004) A combined necking and shear localization analysis for aluminium sheets under biaxial stretching conditions. Int J Plast 20:1953–1981

Dunand M, Mohr D (2010) Hybrid experimental–numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 47:1130–1143

Mellor PB (1956) Stretch forming under fluid pressure. J Mech Phys Solids 5(1):41–56

Mahmudi R (1996) Plastic instability in equi-biaxial deformation of aluminium alloy sheet. J Mater Process Technol 57:266–271

Marciniak Z, Kuczyński K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9:609–620

D. Banabic, H.-J. Bunge, K. Pöhlandt A.E. Tekkaya (2000) Formability of metallic materials, Engineering Materials, Springer, Berlin

Guelorget B, François M, Vial-Edwards C, Montay G (2006) Strain rate measurement by ESPI: a new look at the strain localization onset. Mater Sci Eng A 415:234–241

Labergère C, Guelorget B, François M (2014) Strain rate distribution and localization band width evolution during tensile test. Int J Solids Struct 51:3944–3961

Montay G, François M, Tourneix M, Guelorget B, Vial-Edwards C, Lira I (2007) Analysis of plastic strain localization by a combination of the speckle interferometry with the bulge test. Opt Lasers Eng 45:222–228

Montay G, François M, Tourneix M, Guelorget B, Vial-Edwards C, Lira I (2007) Strain and strain rate measurement during the bulge test by electronic speckle pattern interferometry. J Mater Process Technol 18:428–435

Wang ZJ, Liu Y (2010) Investigation on deformation behavior of sheet metals in viscous pressure bulging based on ESPI. J Mater Process Technol 210:1536–1544

Ding L, Lin JP, Min JY, Pang Z, Ye Y (2013) Necking of Q&P Steel during uniaxial tensile test with the aid of DIC technique. Chin J Mech Eng 26:1–6

Tvergaard V (1993) Necking in tensile bars with rectangular cross-section. Comput Methods Appl Mech Eng 103:273–290

Petit J, Montay G, François M (2014) Strain rate measurements by speckle interferometry for necking investigation in stainless steel. Int J Solids Struct 51:540–550

Bao C, Francois M, Le Joncour L (2015) Influence of specimen geometry on strain localization phenomena in steel sheets. Appl Mech Mater 784:514–519

Petit J, Montay G, Francois M (2011) Localisation phenomenon investigation on SMATed stainless steel samples by speckle interferometry. Strain 47:363–371

Richefeu V, Chrysochoos A, Huon V, Monerie Y, Peyroux R, Wattrisse B (2012) Toward local identification of cohesive zone models using digital image correlation. Eur J Mech A Solids 34:38–51

Akhmetzyanov M, Albaut G (2004) Study of large plastic strains and fracture in metal elements by photoelastic coating method. Int J Fract 128:223–231

Chrysochoos A, Louche H (2000) An infrared image processing to analyse the calorific effects accompanying strain localization. Int J Eng Sci 38:1759–1788

Creath K (1985) Phase-shifting speckle interferometry. Appl Opt 24(18):3053–3058

Guelorget B, François M, Montay G (2009) Strain localization band width evolution by electronic speckle pattern interferometry strain rate measurement. Scr Mater 60(8):647–650

Bao C, François M, Le Joncour L (2016) A closer look at the diffuse and localized necking of a metallic thin sheet evolution of the two bands pattern. Strain 52:244–260

Murav’ev TV, Zuev LB (2008) Acoustic emission during the development of a Lüders band in a low-carbon steel. Tech Phys 53(8):1094–1098

Sachse W, Yamaguchi K, Roget J (1991) Acoustic emission: current practice and future directions. ASTM Spec Tech Publ 1077:45

Malen K, Bolin L (1974) A theoretical estimate of acoustic emission stress amplitudes. Phys Status Solidi B 61:645–697

Hsu NN, Simmons JA, Hardy SC (1977) An approach to acoustic emission signal analysis. Theory and experiment. Mater Eval 95:100–106

Scruby CB, Wadley HNG, Hill JJ (1983) Dynamic elastic displacement at tile surface of an elastic half-space due to defect sources. J Phys D Appl 16:1069–1083

Rouby D, Fleischmann P, Duvergier C (1983) Un modèle de source d'émission acoustique pour l'analyse de l'émission continue et de l'émission par salves. Philos Mag A 47:671–687 and 689–705

Gillis PP (1972) Acoustic emission. ASTM Spec Tech Publ 505:20

Fitzgerald ER (1960) Mechanical resonance dispersion and plastic flow in crystalline solids. J Acoust Soc Am 32:1270

James DR, Carpenter SH (1971) Relationship between acoustic emission and dislocation kinetics in crystalline solids. J Appl Phys 42:4685

Fleischmann P, Lakestani F, Baboux JC (1977) Analyse Spectrale et Energétique d'une Source Ultrasonore en Mouvement – Application à l'Emission Acoustique de l'Aluminium soumis à Déformation Plastique. Mater Sci Eng 29:205–212

Kotoul M, Bilek Z (1990) Acoustic emission during deformation and crack loading in structural steels. Int J Press Vessel Pip 44:291–307

Sehofield BH (1964) ASD-TDR-63-509, part II. Lessels and Associates, Waltham Massachusetts

Tetelman AS, Chow R. (1972) Acoustic emission testing and microcracking processes. Am Soc Test Mater Spec Publ 505, p. 30

Deschanel S, Ben Rhouma W, Weiss J (2013) Study of dislocation and fracture dynamics during fatigue of aluminum from acoustic emission data. Proceedings of ICF13, Session: Statistical Physics and Fracture, Beijing

Baram J, Rosen M (1979) Acoustic emission generated during the tensile testing of Aluminium alloys. Mater Sci Eng 40:21–29

Akbari, M, Ahmadi, M. (2009) The application of acoustic emission technique to plastic deformation of low carbon steel. Physics Procedia, 2010, 3:795–801, from International Congress on Ultrasonics, Universidad de Santiago de Chile

Nikitin ES, Semukhin BS, Zuev LB (2008) Localized plastic flow and spatiotemporal distribution of acoustic emission in steel. Tech Phys Lett 34(8):666–667

Fleischmann P (1979) Etude par émission acoustique des propriétés dynamiques des dislocations. Application à la déformation plastique de l’aluminium. PhD Thesis, INSA de Lyon, p. 141

R. Jones, C. Wykes (1989) Holographic and speckle interferometry, 2nd edn. vol. 6, Cambridge Studies in Modern Optics, Cambridge University Press, Cambridge

Cloud G (1995) Optical methods of engineering analysis. Cambridge University Press, NY

Petit J, Wagner D, Ranc N, Montay G, François M (2013) Comparison of different techniques for the monitoring of the Lüders bands development. Proceedings of ICF13, Session: Plasticity, Beijing

Jacquot P (2008) Speckle interferometry: a review of the principal methods in use for experimental mechanics applications. Strain 44:57–69

Ghiglia DC, Romero LA (1996) Minimum Lp-norm two-dimensional phase unwrapping. Opt Soc Am 13:1999–2013

Petit J (2010) Elastic-plastic behaviour and strain localisation – Multi-scale study by ESPI and acoustic emission. PhD Thesis, University of Technology of Troyes

Haneef T, Lahiri BB, Bagavathiappan S, Mukhopadhyay CK, Philip J, Rao BPC, Jayakumar T (2015) Study of the tensile behavior of AISI type 316 stainless steel using acoustic emission and infrared thermography techniques. J Mater Res Technol 4(3):241–253

Mielnik EM (1996) Metalworking science and engineering, McGraw-Hill, pages 156 to 160

Maziere M, Forest S (2015) Strain gradient plasticity modeling and finite element simulation of Luders band formation and propagation. Contin Mech Thermodyn 27(1–2):83–104

Zhu Y, Vaillant J, François M, Montay G, Bruyant A (2017) Co-axis digital holography based on sinusoidal phase modulation using generalized lock-in detection. Appl Opt 56(13):F97–F104

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Petit, J., Montay, G. & François, M. Strain Localization in Mild (Low Carbon) Steel Observed by Acoustic Emission - ESPI Coupling during Tensile Test. Exp Mech 58, 743–758 (2018). https://doi.org/10.1007/s11340-018-0379-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-018-0379-2