Abstract

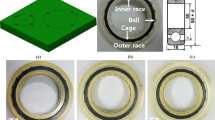

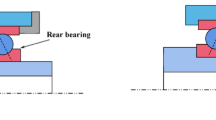

Although stress analysis of the bearing contact problem has been a subject of significant interest, it is rare to find experimental studies on the topic. The problem is attributed to the difficulty in designing an experimental system, which can apply radial and axial loads and permit direct measurement of the bearing contact stresses. A novel experimental configuration is presented which simultaneously applies radial and axial ball bearing loads on a bearing housing into which an assembled photoelastic model of the bearing is mounted. The technique is demonstrated and validated by measuring contact stresses of angular contact ball bearings using the “frozen stress” photoelastic experimental hybrid method (PEHM). Experimental results reveal that ball deformations are mainly concentrated at the contact points. Ball 0, positioned at the base of the bearing housing, experienced the highest magnitude of stresses located near the geometric center of the contact region. Stresses are observed to progressively decrease with increased distance from ball 0 along the circular bearing groove toward balls 4 L and 4R (near the three and nine o-clock positions) where the lowest stress magnitudes were observed. It was also shown that the most highly loaded balls were located in the lower semi-circular section. PEHM measurements are found to be in very good agreement with finite element analysis.

Similar content being viewed by others

References

Pandiyarajan R, Starvin MS, Ganesh KC (2012) Contact stress distribution of large diameter ball bearing using Hertzian elliptical contact theory. Procedia Eng 38:264–269

Tang Z, J-P SUN (2011) The contact analysis for deep groove ball bearing based on ANSYS. Procedia Eng 23:423–428

Bourdon A, Rigal J, Play D (1999) Static rolling bearing models in a C.A.D. environment for the study of complex mechanisms: part II-complete assembly. Model J Tribol 121(2):215–223

Kanga Y, Shen P-C (2006) A modification of the Jones Harris method for deep-groove ball bearings. Tribol Int 39(11):1413–1420

Starvin MS, Babu S, Sriramachandra A, Manisekar K, Chellapandi P (2013) Finite element simulation of non- linear deformation behaviour in large diameter angular contact thrust bearing. SRE 8(3):128–138

Durelli AJ, Wu D (1983) Use of coefficients of influence to solve some inverse problems in plane eleasticity. J Appl Mech 50:288–296

Durelli AJ, Wu D (1984) Loads between disks in a system of discrete elements. Exp Mech 25:337–341

Medri G, Strozzi A (1984) Mechanical analysis of elastomeric seals by numerical methods. Ind Eng Chem Prod Res Dev 23(4):596–600

Hawong JS, Lin CH, Rhee J, Rowlands RE (1995) A hybrid method to determine individual stresses in orthotropic composites using only measured isochromatic data. J Compos Mater 29(18):2366–2387

Lin ST, Rowlands RE (1999) Hybrid stress analysis. Opt Lasers Eng 32:257–298

Ramesh K (2000) Digital Photoelasticity: advanced techniques and application. Springer Verlag, Berlin, Germany

Nam JH, Hawong JS, Han SL, Park SH (2008) Contact stress of O-ring under uniform squeeze rate by photoelastic experimental hybrid method. J Mech Sci Technol 22(12):2337–2349

Azianou EA, Debray K, Bolaers F, Chiozzi P, Palleschi F (2013) Modeling of the behavior of a deep groove ball bearing in its housing. JAMP 1:45–50

Harris TA and Kotzalas MN (2007) Rolling Bearing Analysis, Essential Concepts of Bearing Technology, 5th ed., CRC Taylor & Francis Group, Boca Raton, Florida

Swain D, Philip J, Pillai SA, Ramesh K (2016) A revisit to the frozen stress phenomena in Photoelasticity. Exp Mech 56:903–917

Mose BR, Shin DK, Shin DC (2017) Investigating the performance of seals using photoelastic experimental hybrid method and finite element analysis. J Adv Mech Des Syst 11(2):1–12

Muskhelishvili NI (1963) Some basic problems of mathematical theory of elasticity, 4th edition, P. Noordhoff Ltd., Groningen

Bazaraa MS, Shetty CM (1979) Nonlinear programming theory and algorithms. John Wiley & Sons Inc, U.S.A.

NTN Corporation (2015) Ball and Roller Bearings, CAT. NO. 2202-XII/E

Pavlov VG (2008) Wear calculations for radial ball bearings. Russ Eng Res 28(7):643–650

Ma S-Y, Zhang J-G (2010) Contact analysis on rolling bearing by finite element method. Machinery Design & Manufacture 9:8–10

Shin DC, Nam JH, Hawong JS, Lee JH (2009) Influences of biaxial tensile loads on the stress fields near the mixed mode crack. J Mech Sci Technol 23:2320–2329

Shin DC, Hawong JS, Lee SW, Alunda OB, Lim HS (2014) Contact behavior analysis of X-ring under internal pressure and uniform squeeze rate using photoelastic experimental hybrid method. J Mech Sci Technol 28(10):4063–4073

Acknowledgements

This work was supported by the 2016 Yeungnam University Research Grant. This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2015R1D1A1A01061205).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mose, B.R., Shin, D.K. & Nam, J.H. Development of an Experimental System to Measure Stresses in a Bearing Using Photo-elasticity. Exp Mech 58, 437–447 (2018). https://doi.org/10.1007/s11340-017-0361-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-017-0361-4