Abstract

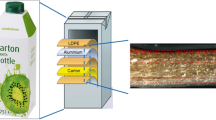

Laminated paperboard is widely used in packaging products. Interface delamination plays a crucial role in converting paperboard to a carton through the creasing and folding process. Thus, the aim of this study is to experimentally and numerically investigate the interface fracture behavior in pure crack opening mode (mode I) and sliding mode (mode II). Four experimental tests have been evaluated and compared to numerical simulation, namely, the z-directional tensile test (ZDT), double-notch shear test (DNS), double-cantilever beam test (DCB) and end-notched flexure test (ENF). It was shown that, for the paperboard specimens tested, the ZDT test was sufficient to fully characterize the mode I crack growth response. However, the DNS and ENF tests were required to determine the maximum shear stress and the fracture toughness of pure mode II, respectively. Further mixed-mode investigation would enable the analysis of paperboard delamination behavior during the creasing and folding process.

Similar content being viewed by others

References

Alava M, Niskanen K (2006) The physics of paper. Rep Prog Phys 69(3):669

Andersson C, Fellers C (2012) Evaluation of the stress-strain properties in the thickness direction–particularly for thin and strong papers. Nord Pulp Pap Res J 27(2):287

Beex LAA, Peerlings RHJ (2009) An experimental and computational study of laminated paperboard creasing and folding. Int J Solids Struct 46(24):4192–4207

Bolzon G, Talassi M (2014) A combined experimental and numerical study of the behaviour of paperboard composites up to failure. Compos Part B 66:358–367

Borgqvist E, Wallin M, Ristinmaa M, Tryding J (2015) An anisotropic in-plane and out-of-plane elasto-plastic continuum model for paperboard. Compos Struct 126:184–195

Carlsson L, Deruvo A, Fellers C (1983) Bending properties of creased zones of paperboard related to interlaminar defects. J Mater Sci 18(5):1365–1373

Carlsson LA, Gillespie JW, Pipes RB (1986) On the analysis and design of the end notched flexure (enf) specimen for mode-ii testing. J Compos Mater 20(6):594–604

Conde I, García B, Liarte E, Jiménez MA (2012) Analysis of adhesive joints in corrugated board under shear loading. Int J Adhes Adhes 38:50–57

Considine JM, Pierron F, Turner KT, Vahey DW (2014) General anisotropy identification of paperboard with virtual fields method. Exp Mech 54(8):1395–1410

Davies P, Sims GD, Blackman BRK, Brunner AJ, Kageyama K, Hojo M, Tanaka K, Murri G, Rousseau C, Gieseke B, Martin RH (1999) Comparison of test configurations for determination of mode ii interlaminar fracture toughness results from international collaborative test programme. Plast Rubber Compos 28 (9):432–437

Fellers C, Östlund S, Mäkelä P (2012) Evaluation of the scott bond test method. Nord Pulp Pap Res J 27(2):231–236

Fischer WJ, Hirn U, Bauer W, Schennach R (2012) Testing of individual fiber-fiber joints under biaxial load and simultaneous analysis of deformation. Nord Pulp Pap Res J 27(2):237–244

Hirn U, Schennach R (2015) Comprehensive analysis of individual pulp fiber bonds quantifies the mechanisms of fiber bonding in paper. Sci Rep:5

Huang H, Nygårds M (2011) Numerical and experimental investigation of paperboard folding. Nord Pulp Pap Res J 26(4):452–467

Isaksson P, Gradin P, Östlund S (2010) A simplified treatise of the scott bond testing method. Exp Mech 50(6):745–751

Korin C, Lestelius M, Tryding J, Hällback N (2007) Y-peel characterization of adhesively-bonded carton board: an objective method. J Adhes Sci Technol 21(2):197–210

Koubaa A, Koran Z (1995) Measure of the internal bond strength of paper board. Tappi J 78(3):103–111

Magnusson MS, Östlund S (2013) Numerical evaluation of interfibre joint strength measurements in terms of three-dimensional resultant forces and moments. Cellulose 20(4):1691–1710

Magnusson MS, Zhang X, Östlund S (2013) Experimental evaluation of the interfibre joint strength of papermaking fibres in terms of manufacturing parameters and in two different loading directions. Exp Mech 53 (9):1621–1634

Nygårds M (2008) Experimental techniques for characterization of elastic-plastic material properties in paperboard. Nord Pulp Pap Res J 23(4):432–437

Nygårds M, Fellers C, Östlund S (2007) Measuring out-of-plane shear properties of paperboard. J Pulp Pap Sci 33(2):105– 109

Nygårds M, Just M, Tryding J (2009) Experimental and numerical studies of creasing of paperboard. Int J Solids Struct 46(11–12):2493–2505

Schmied FJ, Teichert C, Kappel L, Hirn U, Bauer W, Schennach R (2013) What holds paper together: Nanometre scale exploration of bonding between paper fibres. Sci Rep:3

Stenberg N, Fellers C, Östlund S (2001) Measuring the stress-strain properties of paperboard in the thickness direction. J Pulp Pap Sci 27(6):213–221

Stenberg N, Fellers C (2002) Out-of-plane poisson’s ratios of paper and paperboard. Nord Pulp Pap Res J 17(4):387–394

Stier B, Simon J-W, Reese S (2015) Comparing experimental results to a numerical meso-scale approach for woven fiber reinforced plastics. Compos Struct 122:553–560

Tjahjanto DD, Girlanda O, Östlund S (2015) Anisotropic viscoelastic–viscoplastic continuum model for high-density cellulose-based materials. J Mech Phys Solids 84:1–20

Turon A, Davila CG, Camanho PP, Costa J (2007) An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng Fract Mech 74(10):1665– 1682

Xia QXS, Boyce MC, Parks DM (2002) A constitutive model for the anisotropic elastic-plastic deformation of paper and paperboard. Int J Solids Struct 39(15):4053–4071

Acknowledgments

The first author gratefully acknowledges the financial support of the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Stapleton, S., Simon, JW. et al. Experimental and Numerical Study of Paperboard Interface Properties. Exp Mech 56, 1477–1488 (2016). https://doi.org/10.1007/s11340-016-0184-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0184-8