Abstract

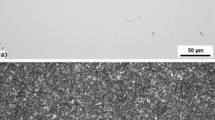

Crack length evaluations for cyclic loading and sustained loading at high temperature and a mix of both have been conducted on Inconel 718 surface crack specimens at 550 ∘C. The choice of method for evaluating the crack length is seen to have a non-negligible impact on the resulting crack propagation rate values. In this paper, some aspects regarding how to evaluate such testing when using the potential drop technique are presented, with the aim of giving a firm explanation on how to proceed for the best possible result.

Similar content being viewed by others

References

Pédron JP, Pineau A (1982) The effect of microstructure and environment on the crack growth behaviour of Inconel 718 alloy at 650 ∘C under fatigue, creep and combined loading. Material Science and Engineering 56(2):143–56

Larsen JM, Nicholas T (1983) Load sequence crack growth transients in a superalloy at elevated temperature. Fracture Mechanics: Fourteenth Symposium - Volume II: Testing and Applications, ASTM STP 791:II–536–II–552

Nicholas T, Weerasooriya T (1986) Hold-time effects in elevated temperature fatigue crack propagation. Fracture Mechanics: 17th Volume, ASTM STP 905:155–168

Weerasooriya T (1987) Effect of frequency on fatigue crack growth rate of Inconel 718 at high temperature. Air Force Wright Aeronautical Laboratories Report, AFWAL-TR-87-4038, Wright-Patterson Air Force Base, OH

Ghonem H, Zheng D (1992) Depth of intergranular oxygen diffusion during environment-dependent fatigue crack growth in alloy 718. Mater Sci Eng A A150(2):151–60

Andrieu E, Molins R, Ghonem H, Pineau A (1992) Intergranular crack tip oxidation mechanism in a nickel-based superalloy. Mater Sci Eng: A 154(1):21–28

Ghonem H, Nicholas T, Pineau A (1993) Elevated temperature fatigue crack growth in alloy 718-part II: Effects of environmental and material variables. Fatigue & Fracture of Engineering Materials & Structures 16(6):577–590

Pfaendtner J A, McMahon CJ Jr (2001) Oxygen-induced intergranular cracking of a Ni-base alloy at elevated temperatures - an example of dynamic embrittlement. Acta Materialia 49(16):3369–3377. doi:10.1016/S1359-6454(01)00005-2

Antunes F V, Ferreira J M, Branco CM, Byrne J (2001) Influence of stress state on high temperature fatigue crack growth in Inconel 718. Fatigue & Fracture of Engineering Materials & Structures 24(2):127–135. doi:10.1046/j.1460-2695.2001.00375.x

Gustafsson D, Moverare J J, Johansson S, Hörnqvist M, Simonsson K, Sjöström S, Sharifimajda B (2010) Fatigue crack growth behaviour of Inconel 718 with high temperature hold times. Procedia Engineering 2(1):1095–1104. doi:10.1016/j.proeng.2010.03.118

Bika D, Pfaendtner J A, Menyhard M, McMahon CJ Jr (1995) Sulfur-induced dynamic embrittlement in a low-alloy steel. Acta Metallurgica et Materialia 43(5):1895–908. doi:10.1016/0956-7151(94)00388-X

Liu X B, Ma L Z, Chang KM, Barbero E (2005) Fatigue crack propagation of Ni-based superalloys. Acta Metallurgica Sinica 18(1):55–64

Krupp U (2005) Dynamic embrittlement - time-dependent quasi-brittle intergranular fracture at high temperatures. Int Mater Rev 50(2):83–97. doi:10.1179/174328005X14320

Woodford DA (2006) Gas phase embrittlement and time dependent cracking of nickel based superalloys. Energy Materials: Materials Science and Engineering for Energy Systems 1(1):59–79. doi:10.1179/174892306X99679

Krupp U, Kane W M, Liu X, Dueber O, Laird C, McMahon CJ Jr (2003) The effect of grain-boundary-engineering-type processing on oxygen-induced cracking of IN718. Mater Sci Eng: A 349(1-2):213–217. doi:10.1016/S0921-5093(02)00753-0

Viskari L, Hörnqvist M, Moore K L, Cao Y, Stiller K (2013) Intergranular crack tip oxidation in a Ni-base superalloy. Acta Materialia 61(10):3630–3639. doi:10.1016/j.actamat.2013.02.050

Lundström E, Simonsson K, Gustafsson D, Månsson T (2014) A load history dependent model for fatigue crack propagation in Inconel 718 under hold time conditions. Eng Fract Mech 118:17–30. doi:10.1016/j.engfracmech.2014.02.005

McMahon CJ Jr (2006) Comments on identification of SAGBO-induced damage zone ahead of crack tip to characterize sustained loading crack growth in alloy 783. Scripta Materialia 54(2):305–307. doi:10.1016/j.scriptamat.2005.09.030

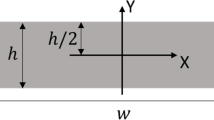

Newman JC Jr, Raju IS (1984) Stress-intensity factor equations for cracks in three-dimensional finite bodies subjected to tension and bending loads NASA Technical Memorandum 85793

Lundström E, Simonsson K, Månsson T, Gustafsson D (2014) Modelling of fatigue crack growth in Inconel 718 under hold time conditions - application to a flight spectrum. Advanced Materials Research 891–892:759–764. doi:10.4028/www.scientific.net/AMR.891-892.759

Acknowledgments

The authors would like to thank Lic. Eng. Mattias Calmunger and Dr. Robert Eriksson, Linköping University, for the SEM support, Mr. Patrik Härnman and Mr. Bo Skoog, Linköping University, for the laboratory work, and the project teams at Linköping University, Siemens Industrial Turbomachinery AB and GKN Aerospace Engine Systems for valuable discussions. This research has been funded by the Swedish Energy Agency, Siemens Industrial Turbomachinery AB, GKN Aerospace Engine Systems, and the Royal Institute of Technology through the Swedish research programme TURBO POWER, the support of which is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Storgärds, E., Simonsson, K. Crack Length Evaluation for Cyclic and Sustained Loading at High Temperature Using Potential Drop. Exp Mech 55, 559–568 (2015). https://doi.org/10.1007/s11340-014-9963-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9963-2