Abstract

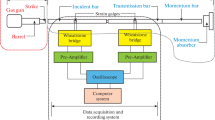

The phase fraction evolution in a material during quasi-static and dynamic tests can be studied by interrupting the test at predetermined elongation values. While it is straightforward to interrupt quasi-static tests at a predetermined level of elongation, this interruption presents difficulties at high strain rate conditions. In the present paper, an interruption mechanism has been developed to control the elongation of specimens at high strain rate using a modified split Hopkinson tensile bar. This interruption mechanism is based on the interaction between the test specimen and the external interruption device. The influence of the designed external device on the stress waves and also the ability of the system to support the interruption of the deformation process were considered in the numerical analysis and verified by the experimental results. Finally, the influences of strain and strain rates on the volume fraction evolution of the retained austenite in quenched & partitioned steel were reported.

Similar content being viewed by others

References

Davis JR (ed). Tensile testing, 2nd edn. ASM International, Materials Park, OH, 44073-0002

Hertzberg RW (1989) Deformation and fracture mechanics of engineering materials, 3rd edn. Wiley, New York

Meyers M (1994) Dynamic behavior of materials. Wiley, New York, p 299

Senuma TT (2001) Physical metallurgy of modern high strength steel sheets. ISIJ Int 41:520

Gussev MN, Busby JT, Byun TS, Parish CM (2013) Twinning and martensitic transformations in nickel-enriched 304 austenitic steel during tensile and indentation deformations. Mater Sci Eng A 588:299–307

Rodriguez-Martinez JA, Pesci R, Rusinek A (2011) Experimental study on the martensitic transformation in AISI 304 steel sheets subjected to tension under wide ranges of strain rate at room temperature. Mater Sci Eng A 528:5974–5982

Ueji R, Takagi Y, Tsuchida N, Shinagawa K, Tanaka Y, Mizuguchi T (2013) Crystallographic orientation dependence of ε martensite transformation during tensile deformation of polycrystalline 30 % Mn austenitic steel. Mater Sci Eng A 576:14–20

Xiong XC, Chen B, Huang MX, Wang JF, Wang L (2013) The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scripta Mater 68:321–324

Villa M, Grumsen FB, Pantleon K, Somers MAJ (2013) Martensitic transformation and stress partitioning in a high-carbon steel. Scripta Mater 67:621–624

Nambu S, Shibuta N, Ojima M, Inoue J, Koseki T, Bhadeshia HKDH (2013) In situ observations and crystallographic analysis of martensitic transformation in steel. Acta Mater 61:4831–4839

Gavriljuk VG, Theisen W, Sirosh VV, Polshin EV, Kortmann A, Mogilny GS, Petrov YN, Tarusin YV (2013) Low-temperature martensitic transformation in tool steels in relation to their deep cryogenic treatment. Acta Mater 61:1705–1715

Cakmak E, Choo H, An K, Ren Y (2012) A synchrotron X-ray diffraction study on the phase transformation kinetics and texture evolution of a TRIP steel subjected to torsional loading. Acta Mater 60:6703–6713

Field JE, Walley SM, Proud WG, Goldrein HT, Siviour CR (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30:725–775

Harding J, Wood EO, Campbell JD (1960) Tensile testing of materials at impact rates of strain. J Mech Eng Sci 2:88–96

Lindholm US, Yeakley LM (1968) High strain-rate testing: tension and compression. Exp Mech 8:1–9

Albertini C, Montagnani M (1976) Wave propagation effects in dynamic loading. Nucl Eng Des 37:115–124

Nicholas T (1981) Tensile testing of materials at high rates of strain. Exp Mech 21:177–185

Staab GH, Gilat A (1991) A direct-tension split Hopkinson bar for high strain-rate testing. Exp Mech 31:232–235

Thakur A, Nemat-Nasser S, Vecchio KS (1996) Dynamic Bauschinger effect. Acta Mater 44:2797–2807

Verleysen P, Degrieck J (2004) Experimental investigation of the deformation of Hopkinson bar specimens. Int J Impact Eng 30:239–253

Nemat-Nasser S, Isacs JB, Starrett JE (1991) Hopkinson techniques for dynamic recovery experiments. J Math Phys Sci 435:371–391

Hosur MV, Alexande J, Vaidya UK, Jeelani S (2001) High strain rate compression response of carbon/epoxy laminate composites. Compos Struct 52:405–417

Jia D, Lennon AM, Ramesh KT (2000) High strain rate pressure-shear recovery: a new experimental technique. Int J Solids Struct 37:1679–1699

El-Saeid Essa Y, Lopez-Puente J, Perez-Castellanos JL (2006) Numerical simulation and experimental study of a mechanism for Hopkinson bar test interruption. J Strain Anal 42:163–172

Ma DF, Chen DN, Wu SX, Wang HR, Hou YJ, Cai CY (2010) An interrupted tensile testing at high strain rates for pure copper bars. J Appl Phys 108:114902

Speer J, Matlock DK, De Cooman BC, Schroth JG (2003) Carbon partitioning into austenite after martensite transformation. Acta Mater 51:2611–2622

Clark AJ, Speer JG, Miller MK, Hackenberg RE, Edmonds DV, Matlock DK, Rizzo FC, Clarke KD, De Moor E (2008) Carbon partitioning to austenite from martensite or bainite during the Quench and Partition (Q&P) process: a critical assessment. Acta Mater 56:16–22

Speer JG, Rizzo-Assunção FC, Matlock DK, Edmonds DV (2005) The “Quenching and Partitioning” process: background and recent progress. Mater Res 8:417–423

Frew DJ, Forrestal MJ, Chen W (2002) Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar. Exp Mech 42:93–106

Frew DJ, Forrestal MJ, Chen W (2005) Pulse shaping techniques for testing elastic–plastic materials with a split Hopkinson pressure bar. Exp Mech 45:186–195

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc Phys Soc (B) 62:676–700

Hallquist JO (2003) LS-DYNA keywords use’s manual (version 970). LSTC, USA

Johnson GR, Cook WH (1983) A constitutive mode and data for metals subjected to large strains, high strain rate and high temperatures. Proceedings of Seventh Int Symposium on Ballistics, pp 541–547

Acknowledgments

The authors gratefully acknowledge the Shanghai Synchrotron Radiation Facility (SSRF) for providing the synchrotron XRD facility of beamline no. B13. The authors acknowledge the financial support from China Science Lab of Research & Development Center of General Motors, the National Nature Science Foundation of China under grant No.11072118, Defence Industrial Technology Development Program No.B1520110003, Zhejiang Provincial Natural Science Foundation of China under grant No.LY12A02003 and the K.C. Wong Magna Fund in Ningbo University. The authors would also like to express their sincere thanks to Baosteel Corporation for supplying the steel material.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Xiong, X., Yin, Z. et al. Interrupted Test of Advanced High Strength Steel with Tensile Split Hopkinson Bar Method. Exp Mech 54, 641–652 (2014). https://doi.org/10.1007/s11340-013-9828-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9828-0