Abstract

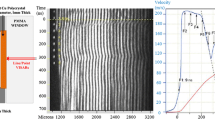

This paper investigates the anisotropy of void evolution and its relation with ductility in the high strength rolled aluminum alloy 7075-T7351. Smooth tension specimens are extracted from three principal material orientations, i.e. rolling (R), transverse (T), and short transverse (S). The mechanical behavior of these specimens is characterized and the varying ductility in the three orientations is clearly observed. Electron Backscattered Diffraction (EBSD), optical microscopy, and Scanning Electron Microscopy (SEM) are employed to characterize the grain structure and the size, location, and chemical composition of the intermetallic particles. In-situ X-ray Tomography (XCT) experiments are performed to obtain tomographic images of the specimens at critical loading steps. The radiographs acquired during the tensile test are then reconstructed and examined through quantitative analysis to partition particles and voids. These tomographic images enable us to visualize void evolution as the specimens are loaded along material orientations. The tomographic images clearly illustrate anisotropy in the void evolution and highlight the importance of local coalescence in developing 1D and 2D void structures prior to global coalescence. Fractography confirms tomography. These findings motivate model forms with appropriate internal variables to adequately describe the dominant mechanisms which govern anisotropic void evolution.

Similar content being viewed by others

References

ASM Handbook, Volume 02 - Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM, 1990. 4.58: 7075, Alclad 7075 5.6Zn-2.5Mg-1.6Cu-0.23Cr

Tirosh J, Shirizly A, Rubinski L (1999) Evolution of anisotropy in the compliances of porous materials during plastic stretching or rolling - analysis and experiments. Mech Mater 31:449–460

Garrison WM, Moody NR (1987) Ductile fracture. J Phys Chem Solids 48(11):1035–1074

Tvergaard V, Needleman A (2006) Three dimensional microstructural effects on plane strain ductile crack growth. Int J Solids Struct 43:6165–6179

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I - yield criteria and flow rules for porous ductile media. J Eng Mater - T ASME 99(1):2–15

Thomason PF (1993) Ductile fracture by the growth and coalescence of microvoids of non-uniform size and spacing. Acta Metall Mater 58:2127–2134

Ortiz M, Molinari A (1992) Effect of strain-hardening and rate sensitivity on the dynamic growth of a void in a plastic material. J Appl Mech - T ASME 59(1):48–53

Weinberg K, Mota A, Ortiz M (2006) A variational constitutive model for porous metal plasticity. Comp Mech 37:142–152

Benzerga AA, Leblond J-P (2010) Ductile fracture by void growth and coalescence. Adv Appl Mech 44:170–297

Agarwal H, Gokhale AM, Horstemeyer MF, Graham S (2002) Quantitative characterization of three-dimensional damage evolution in a wrought al-alloy under tension and compression. Metall Mater Trans A 33A(11):2599–2606

Agarwal H, Gokhale AM, Graham S, Horstemeyer MF (2003) Void growth in 6061-aluminum alloy under triaxial stress state. Mater Sci Eng A 342:35–42

Jordon JB, Horstemeyer MF, Solanki K, Bernald JD, Berry JT, Williams TN (2009) Damage characterization and modeling of a 7075-t651 aluminum plate. Mater Sci Eng A 527:169–178

Baruchel J, Buffiere JY, Maire E, Merle P, Peix G (2000) X-ray tomography in material science.Hermes Science Publications, Paris

Babout L, Ludwig L, Maire E, Buffiere JY (2003) Damage assessment in metallic structural materials using high resolution synchrotron X-ray tomography. Nucl Instrum Meth B 200:303–307

Qian L, Toda H, Uesugi K, Ohgaki T, Kobayashi M, Kobayashi T (2008) Three-dimensional visualization of ductile fracture in an Al-Si alloy by high-resolution synchrotron X-ray microtomography. Mater Sci Eng A 483-484:293–296

Morgeneyer TF, Starink MJ, Sinclair I (2008) Evolution of voids during ductile crack propagation in an aluminum alloy sheet toughness test studied by synchrotron radiation computed tomography. Act Mater 56:1671–1679

Maire E, Zhou S, Adrien J, Dimichiel M (2011) Damage quantification in aluminum alloys using in situ tensile tests in X-ray tomography. Eng Frac Mech 78:2679–2690

Polmear IJ (1995) Light Alloys, Metallurgy of the Light Metals, 3rd edn. Wiley

Barth HD, Launey ME, MacDowell AA, Ager III JW, Ritchie RO (2010) On the effect of X-ray irradiation on the deformation and fracture behavior of human cortical bone. Bone 46:1475–1485

Fischler MA, Bolles RC (1981) Random sample consensus - a paradigm for model-fitting with applications to image-analysis and automated cartography. Communications of The ACM 24(6):381–395. ISSN 0001-0782

Thomason PF (1990) Ductile facture of metals. Pergamon Press

Acknowledgments

Sandia National Laboratories is a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000. The authors greatly appreciate the help from the staff members Alastair MacDowell, Dula Parkinson and Jamie Nasiatka at the Advanced Light Source, Lawrence-Berkeley National Laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, H., Lu, WY., Foulk, J.W. et al. An Examination of Anisotropic Void Evolution in Aluminum Alloy 7075. Exp Mech 53, 1583–1596 (2013). https://doi.org/10.1007/s11340-013-9765-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9765-y