Abstract

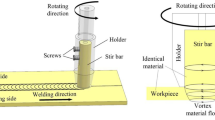

Bronze foil of 0.1 mm thickness was placed between faying surfaces of two plates to be butt-welded as marker material to reveal the flow behavior of weld metal during friction stir welding of 7075-T651 aluminum alloy. By tracing the bronze foil fragments in the weld after welding, the metal flow behavior during the welding process was revealed. Besides, the tool forces in the welding process were measured by the octagonal loop resistance turning dynamometer to expound the periodic variation of metal flow pattern. Results show that the flow behavior of the weld metal is different along the thickness direction. The flow pattern presents a periodic variation, and a formula has been proposed to calculate the periodicity of the metal flow. In addition, the weld nugget zone presents a “spoon” shape and the fine grains at the spoon handle and those at the spoon bowl are originated from different zones. A plastic metal flow model in FSW was proposed based on the results. Furthermore, the formation of defects was explained by researching the weld metal flow behavior.

Similar content being viewed by others

References

Thomas WM, Nicholas ED, Needham JC, Church MG, Templesmith P, Dawes CJ, Patent GB (1991) Friction stir welding. International patent application no. PCT/GB92102203 and Great Britain patent application no. 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1–2):1–78

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding-Process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Dawes CJ, Thomas WM (1996) Friction stir process welds aluminum alloys. Weld J 75(3):41–45

Rhodes CG, Mahoney MW, Bingel WH (1997) Effects of friction stir welding on microstructure of 7075 aluminum. Scripta Mater 36(1):69–75

Xu WF, Liu JH, Chen DL (2011) Material flow and core/multi-shell structures in a friction stir welded aluminum alloy with embedded copper markers. J Alloy Comp 509(33):8449–8454

Leal RM, Leitao C, Loureiro A (2008) Material flow in heterogeneous friction stir welding of thin aluminium sheets: effect of shoulder geometry. Mater Sci Eng 498(1–2):384–391

Buffa G, Hua J, Shivpuri R (2006) Design of the friction stir welding tool using the continuum based FEM model. Mater Sci Eng A-Struct 419(1–2):381–388

Coelho RS, Kostka A, Sheikhi S (2008) Microstructure and mechanical properties of an AA6181-T4 aluminium alloy to HC340LA high strength steel friction stir overlap weld. Adv Eng Mater 10(10):961–972

Cui GR, Ma ZY, Li SX (2008) Periodical plastic flow pattern in friction stir processed Al-Mg alloy. Scripta Mater 58(12):1082–1085

Cui L, Yang XQ, Zhou G (2012) Characteristics of defects and tensile behaviors on friction stir welded AA6061-T4 T-joints. Mater Sci Eng, A 543:58–68

Kim YG, Fujii H, Tsumura T (2003) Three defect types in friction stir welding of aluminum die casting alloy. Mater Sci Eng, A 415(1–2):250–254

Zhang Y, Sato YS, Kokawa H (2008) Microstructural characteristics and mechanical properties of Ti-6Al-4V friction stir welds. Mater Sci Eng, A 485(1–2):448–455

Lee WB, Yeon YM, Jung SB (2003) The improvement of mechanical properties of friction-stir-welded A356 Al alloy. Mater Sci Eng, A 355(1–2):154–159

Liu HJ, Fujii H, Maeda M (2003) Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. J Mater Process Tech 142(3):692–696

Lombard H, Hattingh DG, Steuwer A (2008) Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy. Eng Fract Mech 75(3–4):341–354

Chen HB, Yan K, Lin T (2006) The investigation of typical welding defects for 5456 aluminum alloy friction stir welds. Mater Sci Eng, A 433(1–2):64–69

Zhang H, Lin SB, Wu L (2006) Defects formation procedure and mathematic model for defect free friction stir welding of magnesium alloy. Mater Design 27(9):805–809

Donath T, Beckmann F, Zettlert R (2004) Investigation of material flow in friction stir welding using computed microtomography. 8th International conference on synchrotron radiation instrumentation. San Francisco 705:1312–1315

Seidel TU, Reynolds AP (2001) Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall Mater Trans A 32(11):2879–2884

Schmidt HNB, Dickerson TL, Hattela JH (2006) Material flow in butt friction stir welds in AA2024-T3. Acta Mater 54(4):1199–1209

Hamilton C, Dymek S, Blicharski M (2008) A model of material flow during friction stir welding. Mater Charact 59(9):1206–1214

Silva AA, Arruti E, Janeiro G (2011) Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 aluminum alloys friction stir welds. Mater Design 32(4):2021–2027

Li Y, Murr LE, McClure JC (1999) Flow visualization and residual microstructures associated with the friction-stir welding of 2024 aluminum to 6061 aluminum. Mater Sci Eng, A 271(1–2):213–223

Guerra A, Schmidt C, McClure JC (2002) Flow patterns during friction stir welding. Mater Charact 49(2):95–101

Reynolds AP (2008) Flow visualization and simulation in FSW. Scripta Mater 58(5):338–342

Arora A, Zhang Z, De A (2009) Strains and strain rates during friction stir welding. Scripta Mater 61(6):863–866

Nandan R, Roy GG, Lienert TJ (2006) Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci Technol Weld Joi 11(5):526–537

Qian JW, Li JL, Xiong JT (2012) Periodic variation of torque and its relations to interfacial sticking and slipping during friction stir welding. Sci Tech Weldi Joi 17(4):338–341

Fonda R, Reynolds A, Feng CR (2013) Material flow in friction stir welds. Metall Mater Trans A 44A(1):337–344

Fonda R, Bingert JF (2007) Texture variations in an aluminum friction stir weld. Scripta Mater 57(11):1052–1055

Yan JH, Sutton MA, Reynolds AP (2007) Processing and banding in AA2524 and AA2024 friction stir welding. Sci Tech Weldi Joi 12(5):390–401

Fonda RW, Knipling KE, Bingert JF (2009) Texture development in aluminum friction stir welds. Mater Process Texture 200:17–28

Acknowledgments

The authors would like to thank for financial support the National Natural Science Foundation of China (51005180), the Fok Ying-Tong Education Foundation for Young Teachers in the Higher Education Institutions of China (131052), the Fundamental Research Fund of NPU (JC201233) and the 111 Project (B08040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W.Y., Li, J.F., Zhang, Z.H. et al. Metal Flow during Friction Stir Welding of 7075-T651 Aluminum Alloy. Exp Mech 53, 1573–1582 (2013). https://doi.org/10.1007/s11340-013-9760-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9760-3