Abstract

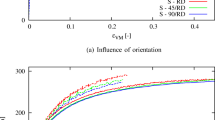

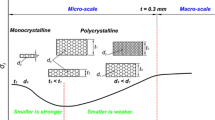

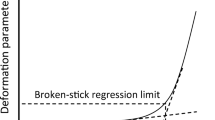

This article extends the concept of forming limit curves to very thin (0.1 mm) metallic materials. The forming limit curves for these materials are referred in this paper as microforming limit curves. To study the microformability of such materials, a microdrawing press based on the Marciniak principle, coupled with an image acquisition system, was designed and built in the laboratory. Images of the sample surface were obtained during the microdrawing process and processed using a deformation measurement system based on image correlation. The microformability of aluminium 1050A (99.5 %) and aluminium alloy (Al-3 % Mg) were characterised in tests at three different geometries and then analysed. Besides, a new technique for estimating the strain at the onset of necking was developed and tested against a proven method. This technique is more easily automated because it does not rely on subjective criteria. Thus, it is possible to have the microforming limit curve for very thin sheet by a rapid and objective experimental method.

Similar content being viewed by others

References

Vollertsen F, Hu Z, Niehoff HS, Theiller C (2004) State of the art in micro forming and investigations into micro deep drawing. J Mater Process Technol 151:70–79

Keeler SP, Backhofen WA (1965) Plastic instability and facture in sheet stretched over rigid punches. ASM Trans Q 56:25–48

Nakazima K, Kikuma T, Hazuka K (1971) Study on the formability of steel sheets. Yawata Tech Rep 284:678–680

Marciniak Z, Kuczynski K (1967) Limit strain in the process of stretch forming sheet metal. Int J Mech Sci 9:609–620

Gronostajski J, Dolny A (1980) Determination of the forming limit curves of Marciniak’s punch. Mem Sci Rev Metall 4:570–578

Rasmussen SN (1981) Theorical prediction of strain path dependence of limit strain in sheet material. CIRP Annal 30(1):179–184

Arrieux R, Chalons J, Bedrin C, Boivin M (1984) Computer aided measurement of grid network deformation for the determination of forming limit diagrams. CIRPS Annal:171–174

Lacombe J (1969) Méthode d’utilisation des grilles susceptible d’aider l’interprétation des emboutis. Colloque GAMI/ISMCM, Paris 25–30

Keeler SP, Brazier WG (1969) Relationship between laboratory material characterisation and press-shop formability. Proc Microalloy Union Carbide New York 75:517–530

Vacher P, Dumoulin S, Morestin F, Mguil-Touchal S (1999) Bidimensional strain measurement using digital images. Proc Inst Mech Eng Part C 213:811

Veerman C, Hartman L, Peels J, Neve P F (1971) Determination of appearing and admissible strain in cold reduced sheets. Sheetmet Ind 678–694

Veerman C, Neve P F (1972) Some aspects of the determination of forming limit diagrams-onset of localized necking. Sheetmet Ind 421–425

Bragard A, Baret JC, Bonnarens H (1972) A simplified technique to determine the FLD at the onset of necking. Proc. IDDRG, Amsterdam, DDR/WGI/21 P/72

Hecker SS (1972) A simple forming limit curve technique and results on aluminium alloys. Proc. 7th International Deep Drawing Research Group Congress, Amsterdam 51

Kobayashi I, Ishiga M, Abe T (1972) of the strain ratio on the deforming limit of steel sheets and its application to actual press forming. Proc. 7th International Deep Drawing Research Group Congress 52–60

Ben Tahar M (2005) Contribution à l’étude et la simulation du procédé d’hydroformage. Doctoral Thesis, Ecole des Mines de Paris

Vacher P, Haddad A, Arrieux R (1999) Determination of forming limit diagrams using image analysis by correlation method. CIRP Ann Manuf Technol 48(1):227–230

Pires GP, Robert MH, Arrieux R (2004) Studies on drawing of the aluminium A 5052 alloy in the thixocast condition. J Mater Process Technol 157–158:596–603

Sène NA, Balland P, Arrieux R, Moreau JM (2011) Micro-deep drawing on aluminium crystals to validate multiscale modelling. Exp Mech. doi:10.1007/s11340-010-9398-3

Balland P, Dumoulin S, Milkansen C, Arrieux R, Sergent A, Barathay S, Hans JR (2007) Détermination des courbes limites de formage sur des matériaux nanostructurés. Proc. 18ème Congrès Français de Mécanique, Grenoble

Chihab K (1986), Etude des instabilités de la déformation plastique associées à l’effet Portevin-Le Châtelier dans les alliages Aluminium-Magnésium. Doctoral Thesis, Université de Poitiers

Louche H, Bouabdallah K, Vacher P, Coudert T, Balland P (2008) Kinematic fields and acoustic emission observations associated with the Portevin-Le Châtelier effect on an Al–Mg alloy. Exp Mech 48(6):741–751

Tabourot L, Vacher P, Coudert T, Toussaint F (2005) Numerical determination of strain localisation during finite element simulation of deep drawing operations. J Mater Process Technol 159:152–158

Sène NA, Balland P, Arrieux R (2008) About necking detection to determine forming limit diagrams for mini stamping. 17th International Scientific and Technical Conference—Design and Technology of Drawpieces and Die Stampings—Poland

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sène, N.A., Balland, P., Arrieux, R. et al. An Experimental Study of the Microformability of Very Thin Materials. Exp Mech 53, 155–162 (2013). https://doi.org/10.1007/s11340-012-9623-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-012-9623-3