Abstract

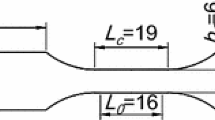

The high temperatures and large strain limits associated with superplastic materials amplify the possibility of the tensile test outcomes being sensitive to the shape and size of the specimen geometry. In spite of that, the disparities in the specimen geometries used throughout the numerous efforts on characterising this unique class of materials are rather astonishing. There is an urge to evaluate the dependency of a superplastic tensile test on specimen geometry, before a much-needed universally-adopted standard specimen can be designed; which is the main objective of this comprehensive experimental investigation. More than 20 geometries, covering multiple variations in gauge length, gauge width, grip length and grip width values, are tested at identical conditions, and the corresponding material behaviour is compared in terms of deformation uniformity, material flow and the extracted stress/strain curves. The results reveal the influences of each geometrical parameter, as well as their combined effects, and guide the selection of an optimum specimen geometry for accurate and unified tensile testing of superplastic metallic materials.

Similar content being viewed by others

References

Verma R, Friedman P, Ghosh KS, Kim C (1996) Characterization of superplastic deformation behavior of a fine grain 5083 Al alloy sheet. Metall Mater Trans 27A:1889–1898

Lee C, Huang J (2004) Cavitation characteristics in AZ31 Mg alloys during LTSP or HSRSP. Acta Mater 52:3111–3122

Chino Y, Iwasaki H, Mabuchi M (2004) Cavity growth rate in superplastic 5083 Al and AZ31 Mg alloys. J Mater Res 19(11):3382–3388

Watanabe H, Takara A, Somekawa H, Mukai T, Higashi K (2005) Effect of texture on tensile properties at elevated temperatures in an AZ31 magnesium alloy. Scr Mater 52:449–454

Mukhopadhyay P, Biswas S, Chokchi A (2009) Deformation characterization of superplastic AA7475 alloy. Trans Indian Inst Met 62(2):149–152

Liu J, Chen D, Chen Z, Yan H (2009) Deformation behavior of AZ31 magnesium alloy during tension at moderate temperatures. J Mater Eng Perform 18(7):966–972

Abu-Farha F, Khraisheh M (2007) Analysis of superplastic deformation of AZ31 magnesium alloy. Adv Eng Mater 9(9):777–783

Chang J, Taleff E, Krajewsky P (2009) Effect of microstructure on cavitation during hot deformation of a fine-grained aluminum-magnesium alloy as revealed through three-dimensional characterization. Metall Mater Trans 40A(13):3128–3137

Hong Y, RongShi C, EnHou H (2009) Superplasticity of Mg-5.8Zn-1Y-Zr alloy sheet fabricated by combination of extrusion and hot-rolling processes. Sci China Ser E: Technol Sci 52(1):166–171

Ma Y, Langdon T (1994) Factors influencing the exceptional ductility of a superplastic Pb-62 pct Sn alloy. Metall Mater Trans 25A(10):2309–2311

Johnson K, Khaleel M, Lavender C, Pitman S, Smith J, Smith M, Hamilton C (1994) The effect of specimen geometry on the accuracy of constitutive relations in a superplastic 5083 aluminum alloy. Mater Sci Forum 170–172:627–632

Johnson K, Khaleel M, Lavender C, Smith M (1995) Accuracy issues in modeling superplastic metal forming. Proceedings of the Annual Meeting of the Minerals Materials and Metals Society, Las Vegas, Nevada

Bate P, Ridley N, Sotoudeh K (2008) Effect of gauge length in superplastic tensile tests. Mater Sci Technol 24(10):1265–1270

Method for evaluation of tensile properties of metallic superplastic materials, JIS H 7501, 2002

Standard test method for determining the superplastic properties of metallic sheet materials, ASTM E2448, 2005

Method for evaluation of tensile properties of metallic superplastic materials, BS ISO 20032, 2007

Khaleel M, Johnson K, Lavender C, Smith M, Hamilton C (1996) Specimen geometry effect on the accuracy of constitutive relations in a superplastic 5083 aluminum alloy. Scr Mater 34(9):1417–1423

Abu-Farha F, Curtis R (2009) Quick-mount grips: towards an improved standard for uniaxial tensile testing of metallic superplastic sheets. Materialwiss Werkstofftech 40(11):836–841

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abu-Farha, F., Nazzal, M. & Curtis, R. Optimum Specimen Geometry for Accurate Tensile Testing of Superplastic Metallic Materials. Exp Mech 51, 903–917 (2011). https://doi.org/10.1007/s11340-010-9396-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-010-9396-5