Abstract

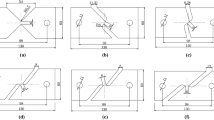

An in-plane shear specimen made of dual phase steel designed for ductile fracture studies is presented and then analyzed experimentally and numerically. In the experiment, digital image correlation (DIC) technique is utilized to measure the deformation of the specimen. Based on the implicit nonlinear FE solver Abaqus/Standard, numerical analysis of the specimen is performed by using plane stress and solid elements respectively. The elongation of the specimen’s gauge length and the shear strain distribution within the shear zone are compared between the experimental and numerical results and a general good agreement is obtained. Thereafter, based on calculated results, the stress state of the shear zone is investigated in detail. It is shown that the shear stress is dominant within the shear zone despite of the emergence of normal stresses. The deformation is concentrated in the shear zone, where the incipient fracture is most likely to occur. The stress triaxiality and the Lode parameter at the fracture initiation are found to be maintained at a relatively low level, which implies that the stress state achieved by the specimen is close to pure shear. The present study demonstrates that the proposed in-plane shear specimen is suitable for investigation of the fracture behavior of high strength materials under shear stress states.

Similar content being viewed by others

References

Jeanneau M, Pichant P (2000) The trends of steel products in the European automotive industry. Text of a conference presented at the 55th Congress of ABM, Brazil

Heimbuch R (2006) An overview of the auto/steel partnership and research needs. report in advanced high strength steel workshop. Arlington, Virginia, USA

G’Sell C, Boni S, Shrivastava S (1983) Application of the plane simple shear test for determination of the plastic behavior of solid polymers at large strains. J Mater Sci 18:903–918

Bouvier S, Haddadi H, Levee P, Teodosiu C (2006) Simple shear tests: experimental techniques and characterization of the plastic anisotropy of rolled sheets at large strains. J Mater Process Technol 172:96–103

Iosipescu N (1967) New accurate procedure for single shear testing of metals. J Mater 2(3):537–566

Walrath D E, Adams D F (1981). The Iosipescu Shear Test as Applied to Composite Materials. Exp Mech, 105–110.

Odegard G, Kumosa M (1999) Elasto-plastic analysis of the Iosipescu shear test. J Compos Mater 33(21):1983–2001

Barnes JA, Kumosa M, Hull D (1987) Theoretical and experimental evaluation of the Iosipescu shear test. Compos Sci Technol 28:251–268

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46:81–98

Tarigopula V, Hopperstad OS, Langseth M et al (2008) A study of large plastic deformations in dual phase steel using digital image correlation and FE analysis. Exp Mech 48:181–196

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Bao Y (2005) Dependence of ductile crack formation in tensile tests on stress triaxiality, stress and strain ratios. Eng Fract Mech 72:505–522

Seppala ET, Belak J, Rudd RE (2004) Effect of stress triaxiality on void growth in dynamic fracture of metals: a molecular dynamics study. Phys Rev B 69:134101

Wierzbicki T, Xue L(2005). On the effect of the third invariant of the stress deviator on ductile fracture. Technical report, Impact and Crashworthiness Laboratory, Massachusetts Institute of Technology, Cambridge, MA.

Bruck HA, McNeill SR, Sutton MA, Peters WH (1988) digital image correlation using Newton-Raphson method of partial differential correction [C]. SEM spring conference on experimental mechanics held in Portland on June 5–10

Zhang D, Eggleton CD, Arola DD (2002) Evaluating the mechanical behavior of arterial tissue using digital image correlation. Exp Mech 42(4):409–416

Belytschko T, Liu WK, Moran B (2000) Finite elements for nonlinear continua & structures. John Wiley & Sons

ABAQUS Theory Manual, Version 6.6 (2006). Hibbitt, Karlsson and Sorensen Inc., Pawtucket, USA

Wierzbicki T, Bao Y, Lee Y-W, Bai Y (2005) Calibration and evaluation of seven fracture models. Int J Mech Sci 47:719–743

Acknowledgements

The present work has been supported financially by National Natural Science Foundation of China (Grant No. 50775120). Thanks are also given to SSAB Swedish Steel Works for supplying DP800 sheet metal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Gui, L. & Fan, Z. Experimental and Numerical Analysis of an In-Plane Shear Specimen Designed for Ductile Fracture Studies. Exp Mech 51, 891–901 (2011). https://doi.org/10.1007/s11340-010-9385-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-010-9385-8