Abstract

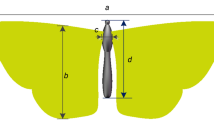

Experiments are performed to determine the mass and stiffness variations along the wing of the blowfly Calliphora. The results are obtained for a pairs of wings of 10 male flies and fresh wings are used. The wing is divided into nine locations along the span and seven locations along the chord based on venation patterns. The length and mass of the sections is measured and the mass per unit length is calculated. The bending stiffness measurements are taken at three locations, basal (near root), medial and distal (near tip) of the fly wing. Torsional stiffness measurements are also made and the elastic axis of the wing is approximately located. The experimental data is then used for structural modeling of the wing as a stepped cantilever beam with nine spanwise sections of varying mass per unit lengths, flexural rigidity (EI) and torsional rigidity (GJ) values. Inertial values of nine sections are found to approximately vary according to an exponentially decreasing law over the nine sections from root to tip and it is used to calculate an approximate value of Young’s modulus of the wing biomaterial. Shear modulus is obtained assuming the wing biomaterial to be isotropic. Natural frequencies, both in bending and torsion, are obtained by solving the homogeneous part of the respective governing differential equations using the finite element method. The results provide a complete analysis of Calliphora wing structure and also provide guidelines for the biomimetic structural design of insect-scale flapping wings.

Similar content being viewed by others

References

Templin RJ (2000) The spectrum of animal flight: insects to pterosaurs. Prog Aerosp Sci 36:393–436

Shyy W, Berg M, Ljungqvist D (1999) Flapping and flexible wings for biological and micro air vehicles. Prog Aerosp Sci 35:455–505

Dickinson MH, Lehmann FO, Sane SP (1999) Wing rotation and the aerodynamic basis of insect flight. Science 284:1954–1960

Maybury WJ, Lehmann FO (2004) The fluid dynamics of flight control by kinematic phase lag variation between two robotic insect wings. J Exp Biol 207:4707–4726

Ellington CP (1999) The novel aerodynamics of insect flight: applications to micro-air vehicles. J Exp Biol 202:3439–3448

Ansari SA, Zbikowski R, Knowles K (2006) Aerodynamic modelling of insect-like flapping flight for micro air vehicles. Prog Aerosp Sci 42:129–172

Szmelter J, Zbikowski R (2002) A study of flow arising from insect wing flapping motion. Int J Numer Methods Fluids 40:497–505

Delauriar JD, Harris JM (1982) Experimental-study of oscillating-wing propulsion. J Aircr 19:368–373

Wang ZJ (2000) Vortex shedding and frequency selection in flapping wing flight. J Fluid Mech 410:323–341

Hall KC, Hall SR (1996) Minimum induced power requirements for flapping flight. J Fluid Mech 323:285–315

Okamoto M, Yasuda K, Azuma A (1996) Aerodynamics characteristics of the wings and body of a dragonfly. J Exp Biol 199:281–294

Wang ZJ (2005) Dissecting insect flight. Annu Rev Fluid Mech 37:183–210

Meyers MA, Chen PY, Lin AYM, Seki Y (2008) Biological materials: structure and mechanical properties. Prog Mater Sci 53:1–206

Wang XS, Li Y, Shi YF (2008) Effects of sandwich microstructures on mechanical behavior of dragonfly wing vein. Compos Sci Technol 68:186–192

Machida K, Oikawa T (2007) Structure analysis of the wings of anotogaster sieboldii and hybris subjacens. Key Eng Mater 345–346:1237–1240

Smith MJC (1996) Simulating moth wing aerodynamics: towards the development of flapping wing technology. AIAA J 34:1348–1355

Wootton RJ, Herbert RC, Young PG, Evans KE (2003) Approaches to the structural modelling of insect wings. Philos Trans R Soc Lond B Biol Sci 358:1577–1587

Combes SA, Daniel TL (2003a) Flexural stiffness in insect wings I. scaling and the influence of wing venation. J Exp Biol 206:2979–2987

Combes SA, Daniel TL (2003b) Flexural stiffness in insect wings II. spatial distribution and dynamic wing bending. J Exp Biol 206:2989–2997

Ennos AR (1988) The importance of torsion in the design of insect wings. J Exp Biol 140:137–160

Ennos AR (1988) The inertial cause of wing rotation in diptera. J Exp Biol 140:161–169

Ennos AR (1995) Mechanical behaviour in torsion of insect wings, blades of grass and other canbered structures. Proc R Soc Lond B Biol Sci 140:161–169

Sunada S, Zeng LJ, Kawachi K (1998) The relationship between dragonfly wing structure and torsional deformation. J Theor Biol 193:39–45

Rosenfeld NC, Wereley NM (2009) Time-periodic stability of a flapping insect wing structure in hover. J Aircr 46:450–464

Barbakadze N, Enders S, Gorb S, Arzt E (2006) Local mechanical properties of the head articulation cuticle in the beetle Pachnoda marginata (Coleoptera, Scarabaeidae). J Exp Biol 209:722–730

Langer MG, Ruppersberg JP, Gorb S (2004) Adhesion forces measured at the level of a terminal plate of the fly’s seta. Proc R Soc Lond B Biol Sci 271:2209–2215

Deng XY, Schenato L, Wu WC, Sastry SS (2006a) Flapping flight for biomimetic robotic insects: part I—System modeling. IEEE Trans Robot 22:776–788

Deng XY, Schenato L, Sastry SS (2006b) Flapping flight for biomimetic robotic insects: part II—Flight control design. IEEE Trans Robot 22:789–803

Gorb SN, Popov VL (2002) Probabilistic fasteners with parabolic elements: biological system, artificial model and theoretical considerations. Philos Trans R Soc Lond Ser A Math Phys Eng Sci 360:211–225

Matushkina N, Gorb S (2007) Mechanical peoperties of the endophytic ovipositor in damselflies (Zygopetra, Odonata) and their oviposition substrates. Zoology 110:167–175

Rao SS (2004) Mechanical vibrations, 4th edn. Pearson Education (Singapore) Pte. Ltd., Indian Branch, Delhi

Bao L, Hu JS, Yu YL, Cheng P, Xu BQ, Tong BG (2006) Viscoelastic constitutive model related to deformation of insect wing under loading in flapping motion. Appl Math Mech 27:741–748

Vincent JFV, Wegst UGK (2004) Design and mechanical properties of insect cuticle. Arthropod Struct Develop 33:187–199

Watson GS, Watson JA (2004) Natural nano-structures on insects—possible functions of ordered arrays characterized by atomic force microscopy. Appl Surf Sci 235:139–144

Cook RD, Malkus RD, Plesha ME, Witt RJ (2005) Concepts and applications of finite element analysis. Wiley, Singapore

Gere JM, Timoshenko SP (1999) Mechanics of materials. Stanley Thrones, Kingston upon Thames

Acknowledgement

The first author thanks the Alexander von Humboldt foundation for providing a fellowship for conducting part of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ganguli, R., Gorb, S., Lehmann, FO. et al. An Experimental and Numerical Study of Calliphora Wing Structure. Exp Mech 50, 1183–1197 (2010). https://doi.org/10.1007/s11340-009-9316-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-009-9316-8