Abstract

The ultimate strength of resistance spot welded joints fabricated from a wide range of steel grades, weld button size, and sheet thickness are reported for lap-shear and cross-tension specimens subjected to quasi-static and impact loading conditions. Test data are analyzed with respect to energy, impact speed, and loading rate. Loading rate is identified as a critical, test system independent parameter to reflect the strain rate sensitivity of the steels. An equation is fitted to the ultimate strength test data as a function of loading rate which is proposed to predict the separation of spot welded joint under dynamic loading. The model is validated by test data from open literature generated from other type of specimens and/or dynamic test conditions.

Similar content being viewed by others

References

Chao, Yuh J., Wang, K., Miller, K.W. and Zhu, X. (2009) “Dynamic separation of resistance spot welded joints: Part I—Experiments,” submitted to Experimental Mechanics. doi:10.1007/s11340-009-9276-z

Ewing, K. W., Cheresh, M., Thompson, R., and Kukuchek, P. (1982) “Static and impact strengths of spot-welded HSLA and low carbon steel joints,” SAE Paper 820281.

Birch RS, Alves M (2000) Dynamic failure of structural joint systems. Thin-walled Struct 36:137–154

Lin S-H, Pan J, Wu S, Tyan T (2004) Failure loads of spot weld specimens under impact opening and shear loading conditions. Exp mech 44(2):147–157

Miller, K. W., Chao, Y.J., Martinez, A., Zhu, X.K., Liu, S. and Wang, P.C. (2003) “Quasi-static and impact strength of fatigue damaged spot welds,” SAE paper 2003-01-0610, also in Welding and Joining, SP-1766, SAE International.

Schneider F, Jones N (2003) Influence of spot-weld failure on crushing of thin-walled structural sections. Int J Mech Sci 45:2061–2081

Sun X, Khaleel MA (2007) Dynamic strength evaluations for self-piercing rivets and resistance spot welds joining similar and dissimilar metals. Int J Imapct Eng 34:1668–1682

Song JH, Huh H, Lim JH, Park SH (2008) Effect of tensile speed on the failure load of a spot weld under combined loading conditions. Int J Mod Phys B 22(9–11):1469–1474

Wang, K and Chao, Y.J., “A new material constitutive model for high strain rate behavior of steels,” in review for publication.

Cowper, G. R. and Symonds, P. S. “Strain hardening and strain rate effects in the impact loading of cantilever beams,” Brown University, Division of Applied Mechanics Report No. 28, 1958.

Johnson, G.R. and Cook, W.H. “A constitutive model and data for metals subjected to large strains, high strain rate and high temperatures,” Proceedings of the Seventh International Symposium on Ballistics, Hague, Netherlands, 541–547, 1983.

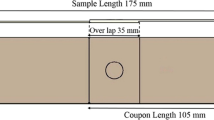

ANSI/AWS/SAE/D8.9–97, Recommended Practices for Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials, American Welding Society, 1997.

Chao YJ (2003) Ultimate strength and failure mechanisms of resistance spot weld subjected to tensile, shear and combined tensile/shear loads ASME. J Eng Mater Technol 125:125–132

Sawhill, J. M., Jr. and Furr, S. T. “Spot Weldability Tests for High-Strength Steels,” SAE 810352, Society of Automotive Engineers 1982

Chao, Y.J. and Wang, K., “Ultimate strength of resistance spot welds made of steels,” manuscript in preparation.

You H, Yum YJ (1997) Loading Rate Effect on Mode I Interlaminar Fracture of Carbon /Epoxy Composite. J Reinf Plast Compos 16(6):537–549

Yoon KK, Van Der Sluys WA, Hour K (2000) Effect of Loading Rate on Fracture Toughness of Pressure Vessel Steels. J Press Vessel Technol 122(2):125–129

Rossi P., Van Mier J.G.M., Toutlemonde F., Le Maou F., and Boulay C., “Effect of loading rate on the strength of concrete subjected to uniaxial tension,” International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 1995, Volume 32(4), 156A–156A(1).

Marone C (1998) The effect of loading rate on static friction and the rate of fault healing during the earthquake cycle. Nature 391:69–72

Zhang Z.X., Kou S.Q., Yu J., Yu Y., Jiang L.G. and Lindqvist P.-A., “Effects of loading rate on rock fracture,” International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 1999, 36(5), 597–611(15).

Needleman A, Rosakis AJ (1999) The effect of bond strength and loading rate on the conditions governing the attainment of intersonic crack growth along interfaces. J Mech Phys Solids 47(12):2411–2449

Courtney AC, Wachtel EF, Myers ER, Hayes WC (1994) Effects of loading rate on strength of the proximal femur. Calcif Tissue Int 55(1):53–8

Race A, Broom ND, Robertson P (2000) Effect of loading rate and hydration on the mechanical properties of the disc. Spine 25(6):662–669

Wang Jaw-Lin, Parnianpour M, Shirazi-Adl A, Engin Ali E (2000) Viscoelastic Finite-Element Analysis of a Lumbar Motion Segment in Combined Compression and Sagittal Flexion: Effect of Loading Rate. Spine 25(3):310–318

Mowery, J., Keener, S., Kuhn, J.E., Chen, V.L., Gatto, J.A. and Hill, S. “Failure of aircraft structural joints under impulse loading,” SAE Paper 965584, 1996.

ASM Handbook, 4th edition, vol.8—Mechanical Testing, ASM International, 1995.

Chao, Y.J., “Failure mode of spot welds: interfacial vs. pullout,” Science and Technology of Welding and Joining, 8(2), pp.133–137, 2003.

Acknowledgement

The authors wish to thank former students from this group, Dr. Shu Liu, Dr. Yil Kim and Mr. Rishi Gaddam, who provided much needed help in preparing the test samples, welding, and maintaining the drop weight apparatus including the high speed data acquisition system. Valuable technical discussions with Drs. P.C.Wang and Yih-Charng Deng of General Motor Corporation are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, K., Chao, Y.J., Zhu, X. et al. Dynamic Separation of Resistance Spot Welded Joints: Part II—Analysis of Test Results and a Model. Exp Mech 50, 901–913 (2010). https://doi.org/10.1007/s11340-009-9277-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-009-9277-y