Abstract

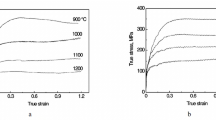

An integrated experimental technique was developed for high-rate mechanical characterization of 304L stainless steel at elevated temperatures by using a modified split Hopkinson pressure bar (SHPB). A sandwich structure consisting of two platens and the specimen in between was heated before mechanical loading while the bars were maintained at room temperature to eliminate the temperature gradient effect on the wave propagation in the bars. Upon contacting the cold bars, temperature gradients form in the platens, leaving the temperature in specimen constant and uniform. Pulse shaping techniques were employed to maintain constant strain-rate deformation and dynamic stress equilibrium in the specimen. Dynamic compressive stress-strain curves at elevated temperatures for the 304L stainless steel were obtained. To relate recrystallization to impact loading, a momentum trapping system was employed to apply a single loading on the specimen during one dynamic experiment. We also controlled the quenching time to study its effect on recrystallization.

Similar content being viewed by others

References

Chiesa M, Antoun B, Brown A, Regueiro R, Jones R, Bamman D, Yang N (2004) Using modeling and simulation to optimize forged material properties. In: Proceedings of the 25th Forging Industry Technical Conference, April 19–21, 2004, Detroit, MI

Brown AA, Bamman DJ, Regueiro RA, Chiesa ML, Antoun BR, Yang N (2005) Modeling the recrystallization behavior of 304L stainless steel. In: 11th International Plasticity Symposium, January, 2005, Kauai, HI

Lee W, Lin C (2001) Impact properties and microstructure evolution of 304L stainless steel. Mater Sci Eng A 308:124–135. doi:10.1016/S0921-5093(00)02024-4

Belyakov A, Miura H, Sakai T (1998) Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel. Mater Sci Eng A 255:139–147. doi:10.1016/S0921-5093(98)00784-9

Ellwood S, Griffiths LJ, Parry DJ (1984) Strain rate and temperature effects at high strain rates in AISI 321 stainless. Inst Phys Conf Ser 70:55–62

Chiddister JL, Malvern LE (1963) Compression-impact testing of aluminum at elevated temperatures. Exp Mech (April), 81–90. doi:10.1007/BF02325890

Frantz CE, Follansbee PS, Wright WT (1984) Experimental techniques with the split Hopkinson pressure bar. In: Proceedings of the 8th International Conference on High Energy Rate Fabrication, Texas, pp 229–236

Rosenberg Z, Dawicke D, Strader E, Bless SJ (1986) A new technique for heating specimens in split-Hopkinson-bar experiments using induction-coil heaters. Exp Mech, (September), 275–278. doi:10.1007/BF02320053

Seo S, Min O, Yang H (2005) Constitutive equation for Ti-6Al-4 V at high temperatures measured using the SHPB technique. Int J Impact Eng 31:735–754. doi:10.1016/j.ijimpeng.2004.04.010

Lennon AM, Ramesh KT (1998) A technique for measuring the dynamic behavior of materials at high temperatures. Int J Plast 14:1279–1292. doi:10.1016/S0749-6419(98)00056-4

Mates SP, Rhorer R, Whitenton E, Burns T, Basak D. A pulse-heated Kolsky bar technique for measuring the flow stress of metals at high loading and heating rates. Exp Mech (online available, doi 10.1007/s11340-008-9137-1)

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc R Soc London B, Biological Sciences 62:679–700

Leroy M, Raad MK, Nkule L, Cheron R (1984) Influence of instantaneous dynamic decremental/incremental strain rate tests on the mechanical behavior of metals—application to high-purity polycrystalline aluminum. In: 3 rd Conference of Mechanical Properties at High Rates of Strain 70, pp 31–38

Song B, Chen W, Antoun BR, Frew DJ (2007) Flow stress obtained on ductile specimens deforming at high strain rates. Exp Mech 47:671–679. doi:10.1007/s11340-007-9048-6

Chen W, Song B, Frew DJ, Forrestal MJ (2003) Dynamic small strain measurements of metal specimen with a split Hopkinson bar. Exp Mech 43:20–23. doi:10.1007/BF02410479

Nemat-Nasser S, Isaacs JB, Starrett JE (1991) Hopkinson techniques for dynamic recovery experiments. Proc Royal Soc A435:371–391. doi:10.1098/rspa.1991.0150

Song B, Chen W (2004) Loading and unloading SHPB pulse shaping techniques for dynamic hysteretic loops. Exp Mech 44:622–627. doi:10.1007/BF02428252

Gray GT (2000) Classic split-Hopkinson pressure bar testing. Mechanical Testing and Evaluation. ASM Handbook 8:462–476

Follansbee PS, Frantz C (1983) Wave propagation in the split Hopkinson pressure bar. ASME Trans J Eng Mater Tech 105:61–66

Song B, Chen W (2005) Split Hopkinson pressure bar techniques for characterizing soft materials. Latin Amer J Solids Struct 2:113–152

Apostol M, Vuoristo T, Kuokkala VT (2003) High temperature high strain rate testing with a compressive SHPB. Journal de Physique IV 110:459–464. doi:10.1051/jp4:20020736

Briggs TL, Campbell JD (1972) The effect of strain rate and temperature on the yield and flow of polycrystalline niobium and molybdenum. Acta Metall 20:711–724. doi:10.1016/0001-6160(72)90100-9

Acknowledgement

The authors would like to thank Dr. Chul Jin Syn for his assistance in dynamic experiments. This work was performed at Purdue University and supported by Sandia National Laboratories. Sandia National Laboratories is operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy under Contract DE-AC04-91AL85000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, B., Antoun, B.R., Nie, X. et al. High-rate Characterization of 304L Stainless Steel at Elevated Temperatures for Recrystallization Investigation. Exp Mech 50, 553–560 (2010). https://doi.org/10.1007/s11340-009-9253-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-009-9253-6