Abstract

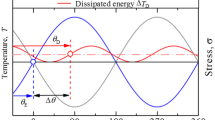

This paper deals with the determination of the thermal response of elastomeric materials subjected to cyclic loading. In this case, the material undergoes large deformations, so a suitable motion compensation technique has been developed to track the material points and their temperature during the test. Special attention is paid to the Narcissus effect and to the detector matrix of the infrared camera used in the study. Heat sources are then derived from the temperature maps. The thermoelastic inversion phenomenon has been experimentally evidenced during a cyclic test performed on an elastomeric notched specimen. The heat source distribution close to the crack tip has also been deduced from the temperature maps, thus highlighting the relevance of the approach.

Similar content being viewed by others

References

Lindley PB, Gent AN, Lake GJ (1964) Cut growth and fatigue of rubbers. I. The relationship between cut growth and fatigue. J Appl Polym Sci 8:455–466

Gent AN, Hindi M (1990) Effect of oxygen on the tear strength of elastomers. Rubber Chem Technol 63:123–134

Greensmith HW (1956) Rupture of rubber. IV. Tear properties of vulcanizates containing carbon black. J Polym Sci 21:175–187

Rivlin RS, Thomas AG (1953) Rupture of rubber. I. Characteristic energy for tearing. J Polym Sci 3:291–318

Thomas AG (1958) Rupture of rubber. V. Cut growth in natural rubber vucanizates. J Polym Sci 31:467–480

Le Cam JB, Huneau B, Verron E, Gornet L (2004) Mechanism of fatigue crack growth in carbon black filled natural rubber. Macromolecules 37:5011–5017

Le Gorju Jago K (2007) Fatigue life of rubber components: 3D damage evolution from X-ray computed microtomography. In: Boukamel A, Laiarinandrasana L, Méo S, Verron E (eds) Constitutive models for rubber. V. Balkema, London

Chrysochoos A, Louche H (2001) Thermal and dissipative effects accompanying luders band propagation. Mater Sci Eng A Struct 307:15–22

Berthel B, Chrysochoos A, Wattrisse B, Galtier A (2007) Infrared image processing for the calorimetric analysis of fatigue phenomena. Exp Mech (in press)

Wattrisse B, Chrysochoos A, Muracciole JM, Némoz-Gaillard M (2001) Analysis of strain localization during tensile tests by digital image correlation. Exp Mech 41(1):29–39

Sakagami T, Nishimura T, Yamaguchi T, Kubo N (2006) Development of a new motion compensation technique in infrared stress measurement based on digital image correlation method. Nihon Kikai Gakkai Ronbunshu A / Trans Jpn Soc Mec Eng 72:1853–1859

Nguyen QS, Germain P, Suquet P (1983) Continuum thermodynamics. J Appl Sci 50:1010–1020

Boccara N (1968) Les principes de la thermodynamique classique. In: PUF coll. SUP

Chrysochoos A, Louche H (2000) An infrared image processing to analyse the calorific effects accompanying strain localisation. Int J Eng Sci 38:1759–1788

Boulanger T, Chrysochoos A, Mabru C, Galtier A (2004) Calorimetric analysis of dissipative and thermoelastic effects associated with the fatigue behavior of steels. Int J Fatigue 26:221–229

Berthel B, Wattrisse B, Chrysochoos A, Galtier A (2007) Thermoelastic analysis of fatigue dissipation properties of steel sheets. Strain 43(3):273–279

Balandraud X, Chrysochoos A, Leclercq S, Peyroux R (2001) Influence of the thermomechanical coupling on the propagation of a phase change front. C R Acad Sci Ser IIB Mec 329(8):621–626

Chrysochoos A, Maisonneuve O, Martin G, Caumon H, Chezeau JC (1989) Plastic and dissipated work and stored energy. Nucl Eng Des 114:323–333

Chrysochoos A, Belmhajoub F (1992) Thermographic analysis of thermomechanical couplings. Arch Mech 44(1):55–68

Granta (2006) CES selector. http://www.grantadesign.com/products/ces/

Mullins L (1948) Effect of stretching on the properties of rubber. Rubber Chem Technol 21:281–300

Zienkiewicz OC (1977) The finite element method in engineering science. McGraw-Hill, London

Gough J (1805) Proc Lit and Phil Soc Manchester, 2nd, ser. 1:288

Joule JP (1857) On some thermodynamic properties of solids. Philos Mag 4th 14:227

Anthony RL, Caston RH, Guth E (1942) Equations of state for naturals and synthetic rubber like materials: unaccelerated natural soft rubber. J Phys Chem 46:826

Acknowledgements

The support of this research by the “Agence Nationale pour la Recherche” is gratefully acknowledged (PHOTOFIT project). Thanks are also due to the French Laboratory of the Trelleborg company for providing the material tested in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pottier, T., Moutrille, MP., Le Cam, JB. et al. Study on the Use of Motion Compensation Techniques to Determine Heat Sources. Application to Large Deformations on Cracked Rubber Specimens. Exp Mech 49, 561–574 (2009). https://doi.org/10.1007/s11340-008-9138-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9138-0