Abstract

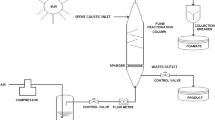

Iron powder is generated as an inevitable solid waste during the processing of the iron-based products in the foundry. This research presented an insight into utilizing the iron powder waste turned into iron powder layer by facile stacking. The iron powder layer could be employed for oil–water separation as it contained numerous coarse irregular-shaped hydrophilic iron particles. The iron powder layer showed a high average oil–water separation efficiency of around 99% for different oil–water mixtures tested along with reasonable flux and intrusion pressure averaging 44 Lm−2 min−1 and 0.4 kPa, respectively. The influence of various thicknesses (1 mm, 3 mm, and 5 mm) of the iron powder layer on oil–water separation performance showed that the flux values drastically declined for higher thicknesses. The iron powder layer also had superior stability in harsh conditions. Application of the iron powder layer for oil–water separation of the oily wastewater collected from the locomotive workshop exhibited almost 100% separation proficiency along with a reasonable flux value of 37.57 Lm−2 min−1, intrusion pressure value of 0.339 kPa, and a high possibility of recycling permeate for washing tasks in the locomotive workshop. Separation effectiveness was detected to be more than 98% even for the fifth cycle indicating prominent reusability of the iron powder layer. Thus, this research demonstrated a pronounced potential for eco-pollution reduction and practical application.

Graphical Abstract

Similar content being viewed by others

Data availability

The data used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Bian, H., Yong, J., Yang, Q., et al. (2020). Simple and low-cost oil/water separation based on the underwater superoleophobicity of the existing materials in our life or nature. Frontiers in Chemistry, 8, 1–7. https://doi.org/10.3389/fchem.2020.00507

Chen, L., Huang, Y., Yang, T., et al. (2020). Laser-structured superhydrophobic/ superoleophilic aluminum surfaces for efficient oil/water separation. Environmental Science and Pollution Research, 27, 43138–43149.

Etchepare, R., Oliveira, H., Azevedo, A., et al. (2017). Separation of emulsified crude oil in saline water by dissolved air flotation with micro and nanobubbles. Separation and Purification Technology, 186, 326–332. https://doi.org/10.1016/j.seppur.2017.06.007

Gupta, R. K., Dunderdale, G. J., England, M. W., et al. (2017). Oil/water separation techniques: A review of recent progresses and future directions. Journal of Materials Chemistry A, 5, 16025–16058.

Lan, W. U., Gang, G. E., & Jinbao, W. A. N. (2009). Biodegradation of oil wastewater by free and immobilized Yarrowia lipolytica W29. Journal of Environmental Sciences, 21, 237–242.

Li, C., Feng, G., Song, C., et al. (2018a). Improved oil removal ability by the integrated electrocoagulation (EC)-carbon membrane coupling with electrochemical anodic oxidation (CM/EAO) system. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 559, 305–313. https://doi.org/10.1016/j.colsurfa.2018.09.043

Li, J., Xu, C., Zhang, Y., et al. (2018b). Gravity-directed separation of both immiscible and emulsified oil/water mixtures utilizing coconut shell layer. Journal of Colloid and Interface Science, 511, 233–242. https://doi.org/10.1016/j.jcis.2017.09.111

Li, J., Zhao, Z., Li, D., et al. (2017). Multifunctional walnut shell layer used for oil/water mixtures separation and dyes adsorption. Applied Surface Science, 419, 869–874.

Li, X., Zhang, W., Liu, N., et al. (2018c). Superwetting copper meshes based on self-organized robust CuO nanorods: Efficient water purification for in situ oil removal and visible light photodegradation. Nanoscale, 10, 4561–4569.

Li, Z., Qian, W., Chen, Y., et al. (2021). A new treasure in industrial solid waste-coal fly ash for effective oil/water separation. Journal of the Taiwan Institute of Chemical Engineers, 118, 196–203. https://doi.org/10.1016/j.jtice.2020.12.026

Li, Z., Wu, J., Yue, X., et al. (2020). Study on the application of waste bricks in emulsified oil-water separation. Journal of Cleaner Production, 251, 119609. https://doi.org/10.1016/j.jclepro.2019.119609

Liu, W., Cui, M., Shen, Y., et al. (2019). Waste cigarette filter as nanofibrous membranes for on-demand immiscible oil/water mixtures and emulsions separation. Journal of Colloid and Interface Science, 549, 114–122. https://doi.org/10.1016/j.jcis.2019.04.057

Liu, Y., Chen, Y., Zhang, W., et al. (2018). A versatile CeO2/Co3O4 coated mesh for food wastewater treatment: Simultaneous oil removal and UV catalysis of food additives. Water Research, 137, 144–152. https://doi.org/10.1016/j.watres.2018.03.007

Otitoju, T. A., Ahmad, A. L., & Ooi, B. S. (2017). Superhydrophilic (superwetting) surfaces : A review on fabrication and application. Journal of Industrial and Engineering Chemistry, 47, 19–40.

Santos, F. S. D., Lago, F. R., Yokoyama, L., et al. (2017). Synthesis and characterization of zero-valent iron nanoparticles supported on SBA-15. Journal of Materials Research and Technology, 6(2), 178–183.

Singhal, R. K., Gangadhar, B., Basu, H., et al. (2012). Remediation of malathion contaminated soil using zero valent iron nano-particles. American Journal of Analytical Chemistry, 3, 76–82. https://doi.org/10.4236/ajac.2012.31011

Wang, J., Liu, S., & Guo, S. (2020a). Calcium ions enhanced mussel-inspired underwater superoleophobic coating with superior mechanical stability and hot water repellence for efficient oil/water separation. Applied Surface Science, 503, 144180. https://doi.org/10.1016/j.apsusc.2019.144180

Wang, J., & Wang, S. (2019). A simple and eco-friendly route for fabricating iron-based coating on metal mesh for efficient oil/water separation. Separation and Purification Technology, 226, 31–38.

Wang, Y., Luo, S., Chen, A., et al. (2020b). Environmentally friendly kaolin-coated meshes with superhydrophilicity and underwater superoleophobicity for oil/water separation. Separation and Purification Technology, 239, 116541. https://doi.org/10.1016/j.seppur.2020.116541

Wenhu, Z., Dejin, W., Ruoyu, F., et al. (2017). Studies on affecting factors and mechanism of oily wastewater by wet hydrogen peroxide oxidation. Arabian Journal of Chemistry, 10, S2402–S2405. https://doi.org/10.1016/j.arabjc.2013.08.022

You, H., Song, G., Liu, Q., et al. (2021). A facile route for the fabrication of a superhydrophilic and underwater superoleophobic phosphorylated PVA-coated mesh for both oil/water immiscible mixture and emulsion separation. Applied Surface Science, 537, 147986. https://doi.org/10.1016/j.apsusc.2020.147986

You, Q., Ran, G., Wang, C., et al. (2018). A novel superhydrophilic – underwater superoleophobic Zn-ZnO electrodeposited copper mesh for efficient oil/water separation. Separation and Purification Technology, 193, 21–28. https://doi.org/10.1016/j.seppur.2017.10.055

Zhang, C., Zhang, T., Huang, J., et al. (2020). Copper hydroxyphosphate nanosheets-covered robust membranes with superhydrophilicity and underwater ultralow adhesive superoleophobicity for oil/water separation and visible light photodegradation. Colloids and Surfaces A, 584, 124000. https://doi.org/10.1016/j.colsurfa.2019.124000

Zhao, B., Ren, L., Du, Y., et al. (2020). Eco-friendly separation layers based on waste peanut shell for gravity-driven water-in-oil emulsion separation. Journal of Cleaner Production, 255, 120184. https://doi.org/10.1016/j.jclepro.2020.120184

Acknowledgements

The authors gratefully acknowledge the kind support of the National Institute of Technology Tiruchirappalli, Tiruchirappalli, Tamil Nadu, India.

Author information

Authors and Affiliations

Contributions

V. Preethi—methodology formulation, performed the experiments, data interpretation, original draft preparation, critical review, editing, and revision of the manuscript. S. T. Ramesh and R. Gandhimathi—provided the resources required to conduct the experiments, validated the results, and supervised the study. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Iron powder waste was turned into an oil-water separating layer by facile stacking.

• Iron powder layer exhibited a very good oil-water separation efficiency.

• Flux drastically declined for higher thickness of the iron powder layer.

• Iron powder layer had superior stability in harsh conditions.

• Iron powder layer was applied for oil-water separation of locomotive wash wastewater.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Preethi, V., Ramesh, S.T. & Gandhimathi, R. Highly Efficacious Oil–Water Separation by Facile Stacking of the Iron Powder Waste. Water Air Soil Pollut 235, 149 (2024). https://doi.org/10.1007/s11270-024-06945-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-06945-5